Installation mechanism and installation method of workbench of multi-station servo hot forging forming machine

A technology of installation mechanism and forming machine, which is applied in the direction of auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the forging and pressing of multi-station servo hot forging forming machines, and the accuracy is not high, so as to increase the operation stability and facilitate Transport and anti-slip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

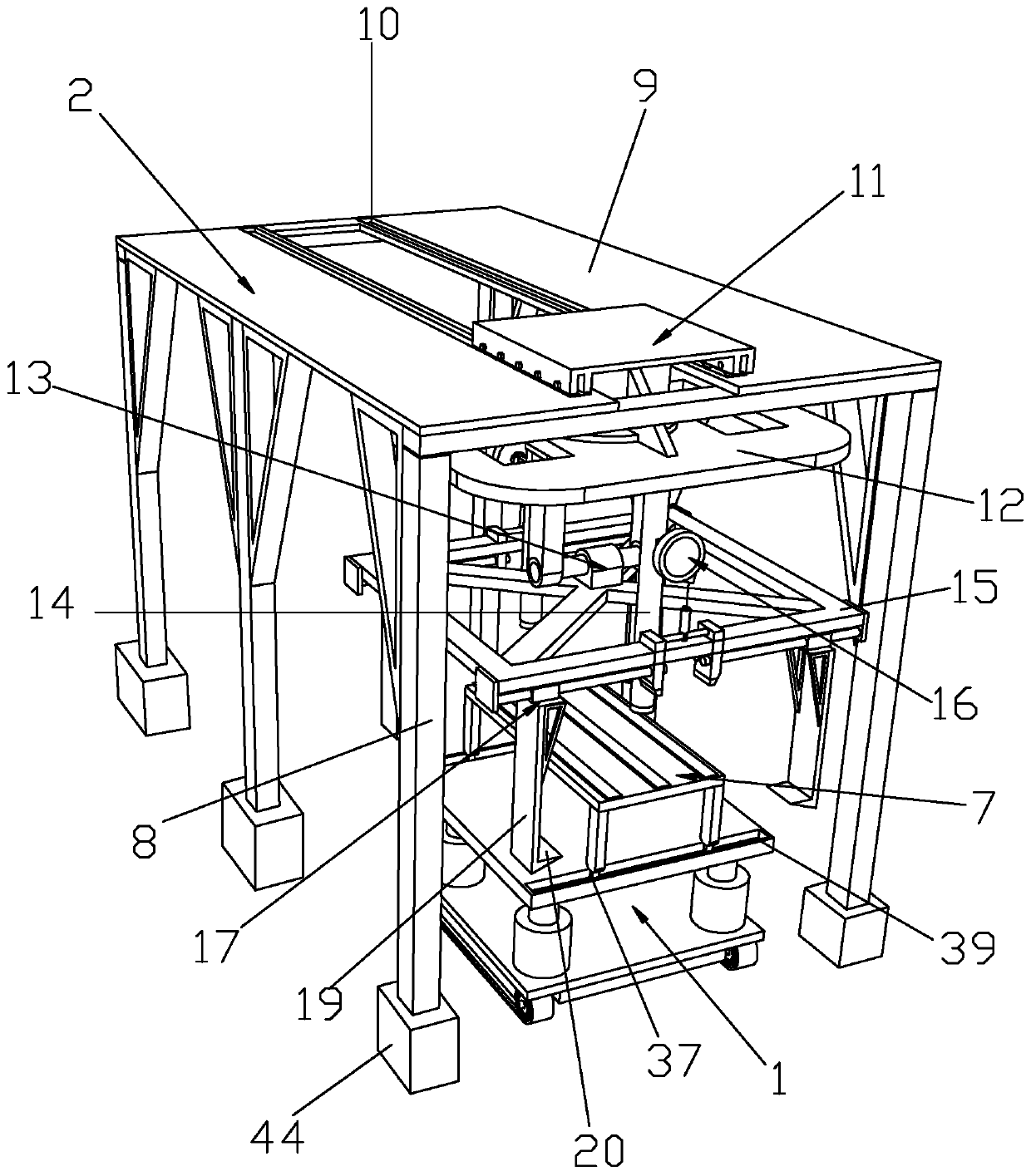

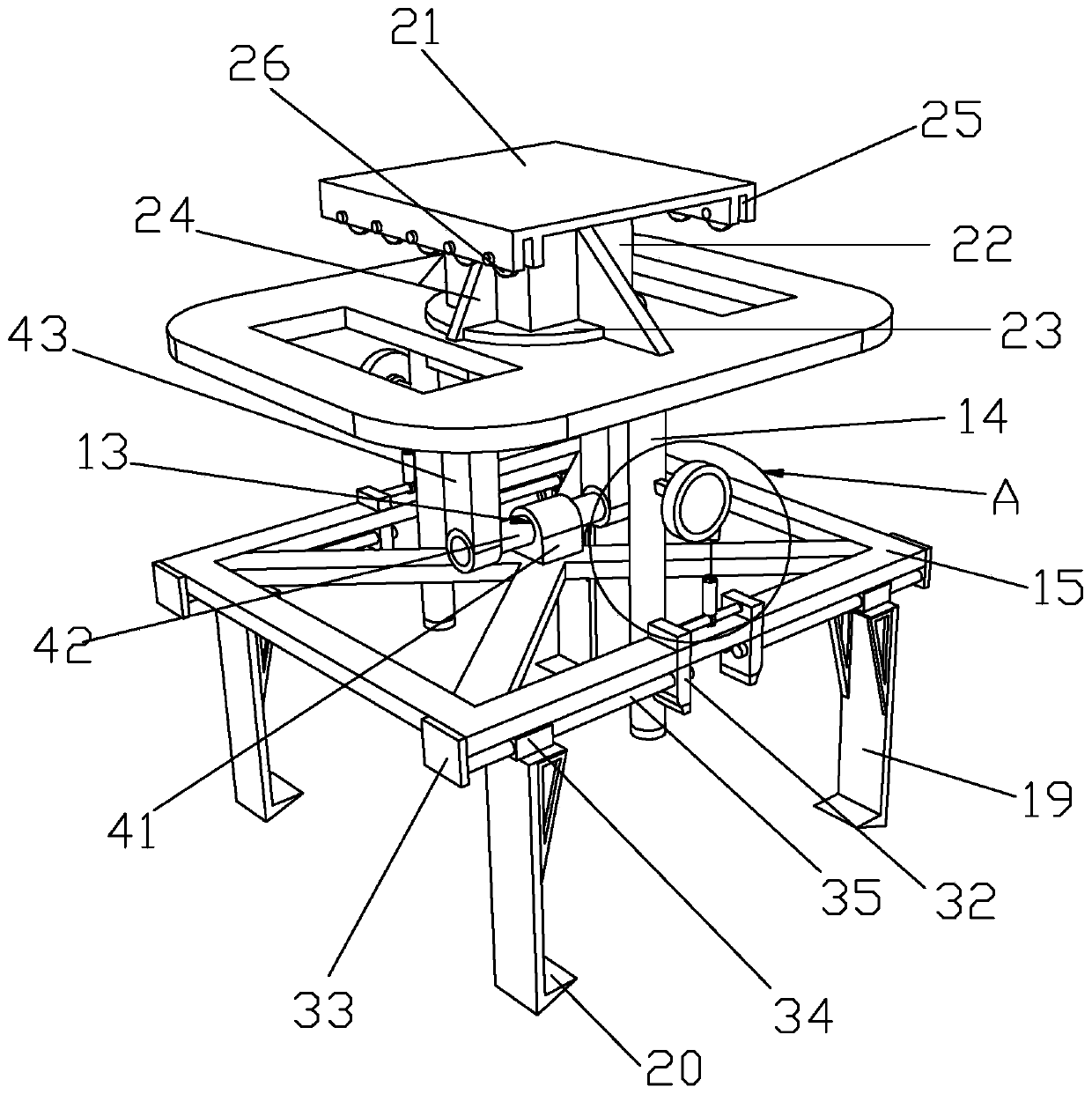

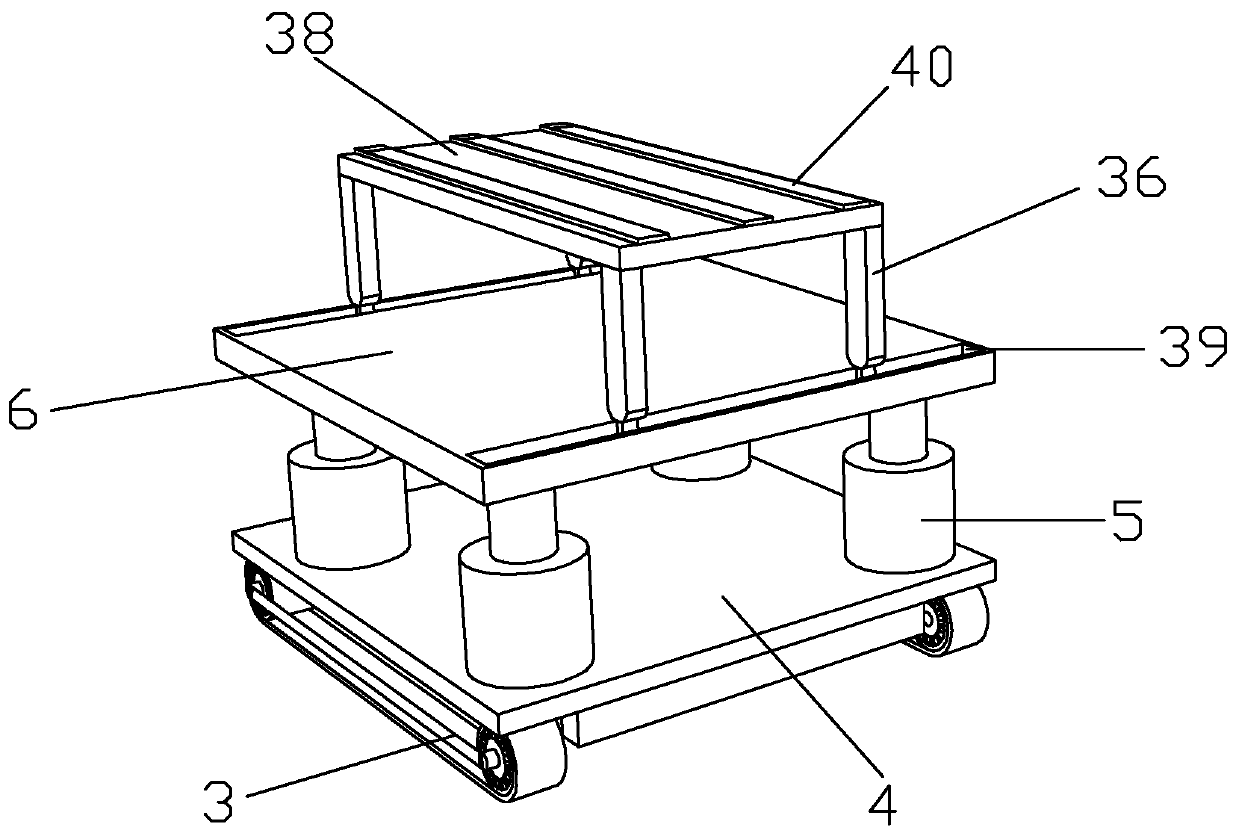

[0038] Such as Figure 1 to Figure 4 As shown, it is the installation mechanism of the workbench of the multi-station servo hot forging machine of the present invention, which includes a transport device 1 and a work frame 2. The transport device 1 includes a pulley 3, a first connecting plate 4, a first cylinder 5, a second connecting Plate 6 and sliding frame 7, sliding frame 7 plays the effect of supporting wedge-shaped workbench. The transport device 1 moves through the pulley 3, which is convenient for transportation; the first cylinder 5 pushes the second connecting plate 6 to move up and down, which is convenient for lifting the wedge-shaped workbench to the position of the clamping device 17, and is convenient for fixing the clamping device 17. And adjust the position of the wedge-shaped worktable to be centered by sliding with the second connecting plate 6 . The belt pulley 3 is connected with the first connecting plate 4, the first connecting plate 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com