Assembled bridge guard plate structure system and construction method thereof

A panel structure and assembled technology, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as extended construction period, hidden safety hazards, and influence on the use effect during the operation period, so as to improve the use effect, strong operability, and realize The effect of factory work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in combination with specific embodiments.

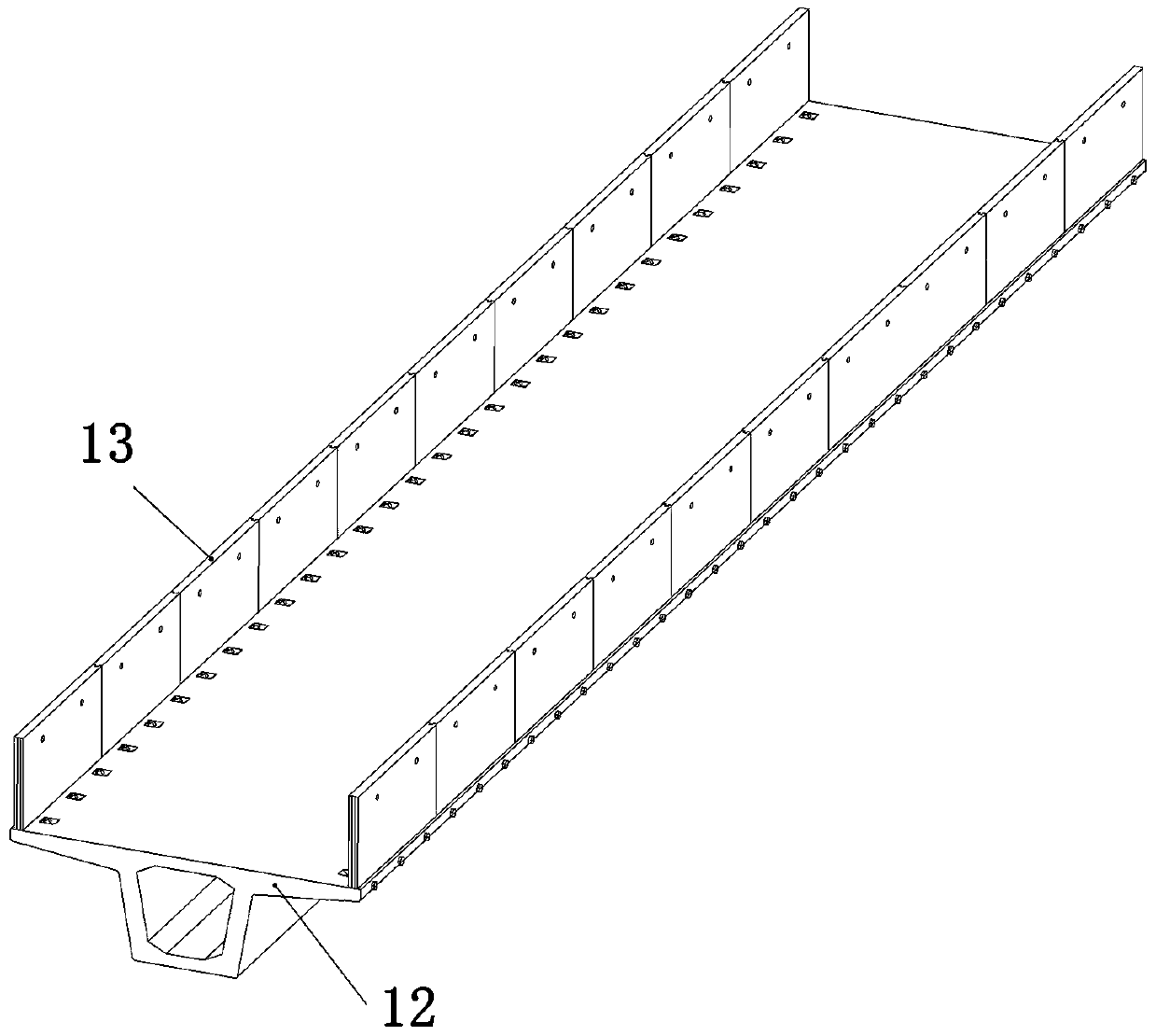

[0039] The present invention relates to an assembled bridge guard plate structure system. The system includes a box girder 12 and a guard plate 13. The guard plate 13 is upright and longitudinally arranged above the flange ends on both sides of the box girder 12. The bottom end of the guard plate 13 is inserted into the box girder. 12 flange plates, fixed and assembled by bolts 10.

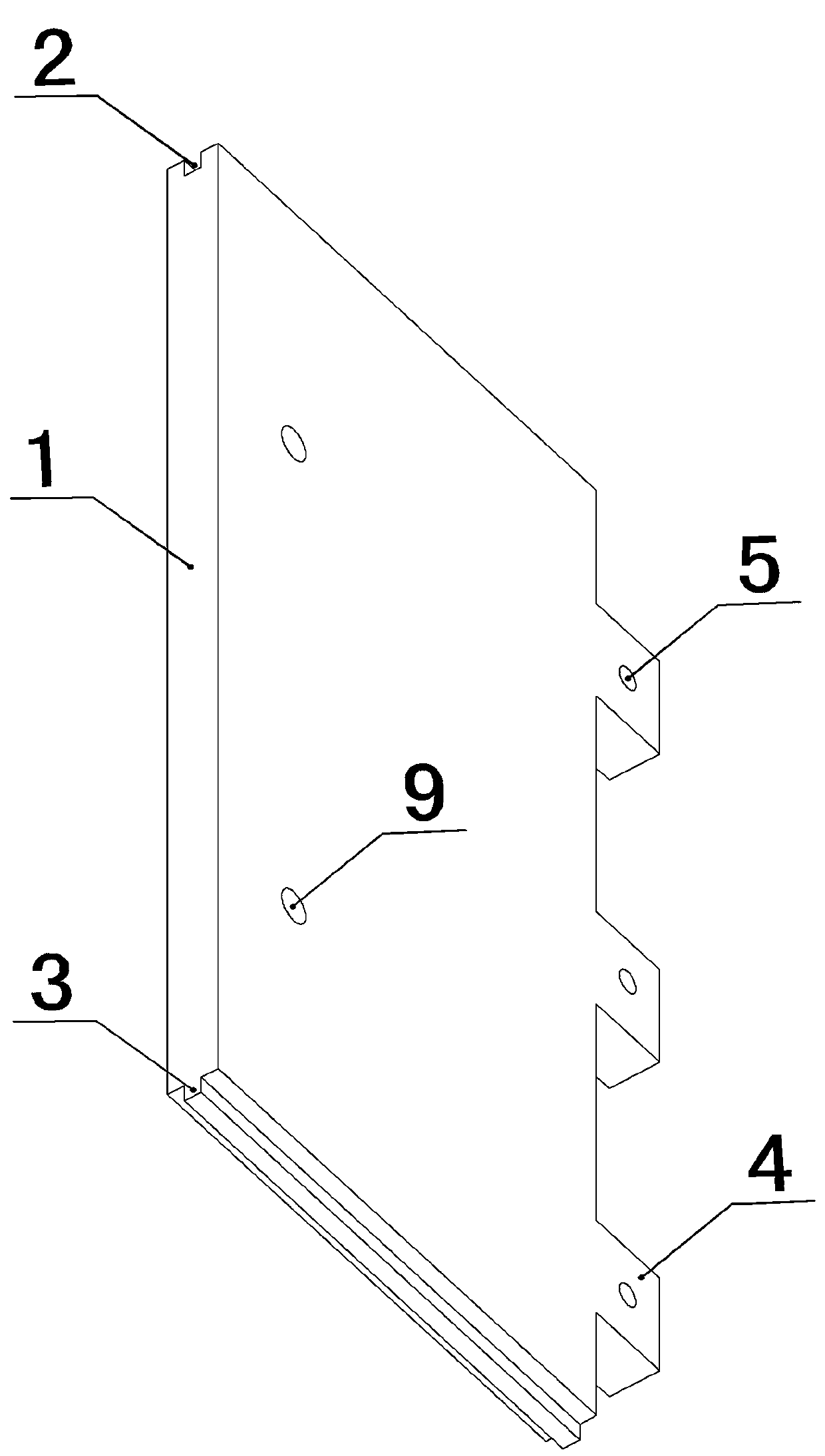

[0040] The guard plate 13 includes a plurality of panels 1 sequentially connected in the longitudinal direction, and strip-shaped tenon 2 and tenon 3 are respectively provided on the front and rear ends of the panel 1 in the longitudinal direction, and the positions are corresponding, and the size and shape match. When the adjacent panels 1 are butted, the corresponding tenon 3 is inserted into the tenon 2 to connect with each other. The tenon 2 and the tenon 3 at both ends of the panel 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com