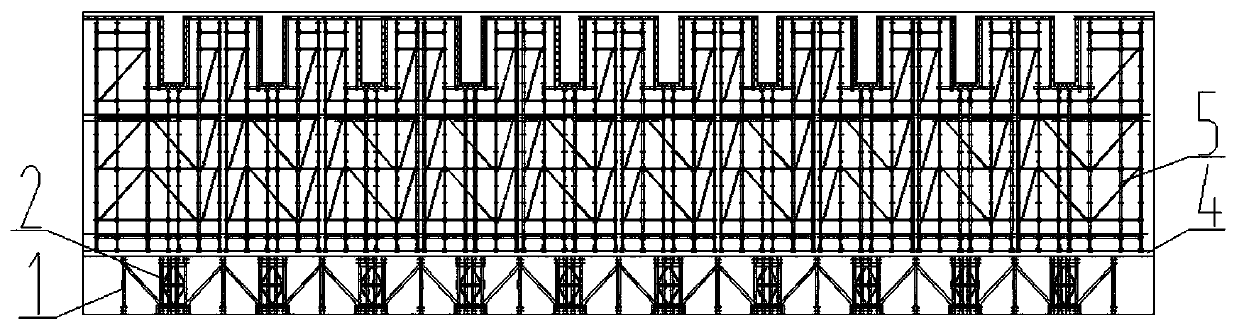

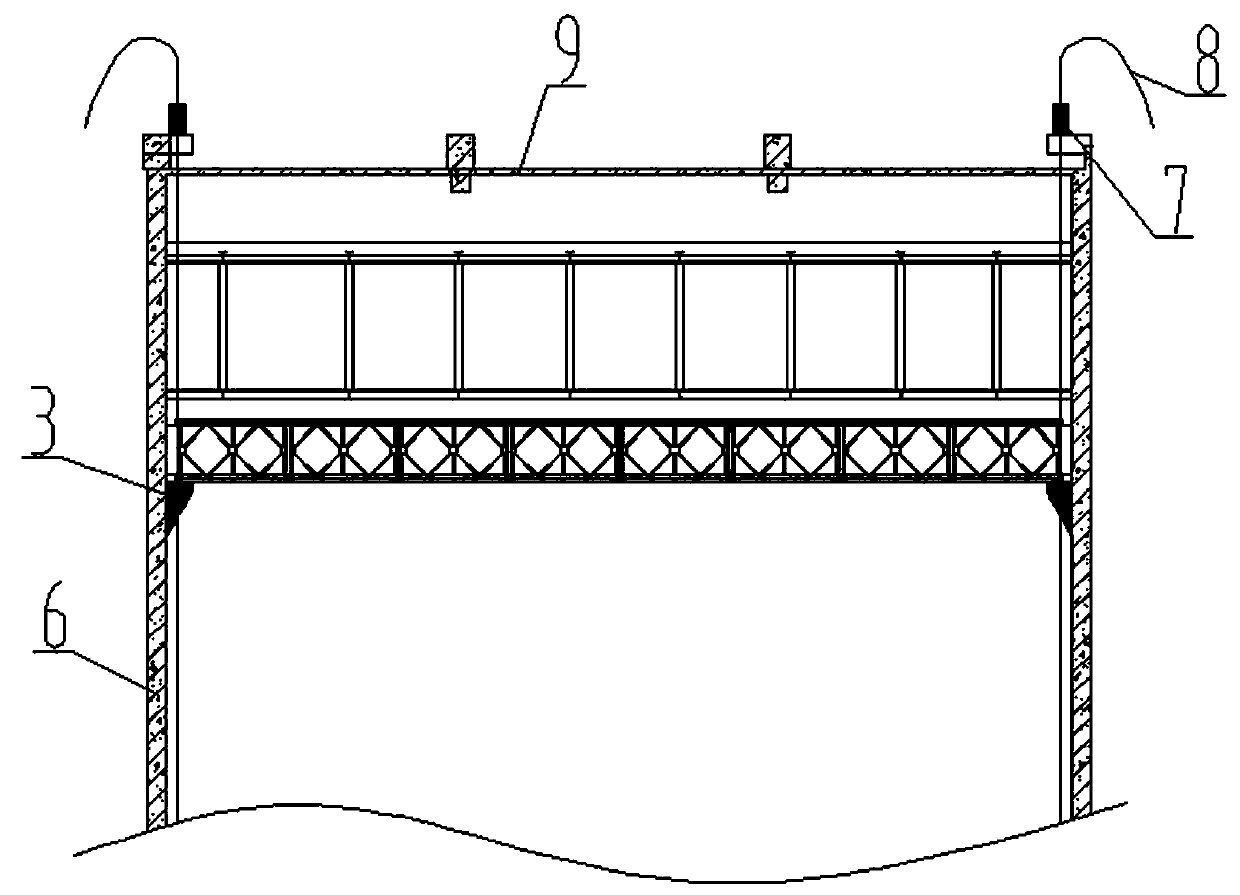

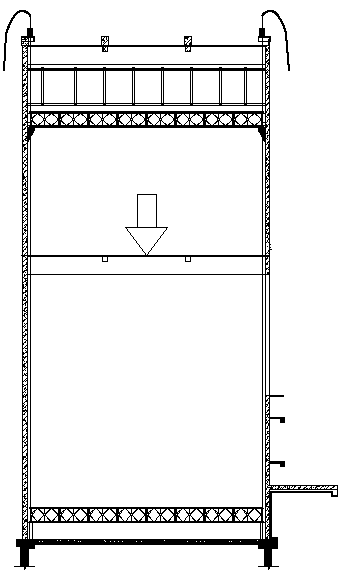

Application and construction method of high-altitude, large-span and heavy-load tool-type formwork supporting steel platform

A formwork support and construction method technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult construction safety, high labor intensity, self-importance, etc., to reduce the risk of personnel operating errors, reduce Construction operation risks and the effect of overcoming poor safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0050] The invention provides the use of a high-altitude large-span heavy-duty structure tool-type formwork supporting steel platform, which is used for the construction platform of the top floor of high-altitude large-span building structures, aerial conjoined structures, high-altitude large-span, and large cantilever structures. The more dangerous construction operations in the air are transformed into pre-assembly operations on the ground to realize the overall installation of the platform on the ground, and the necessary steps such as preloading, testing, acceptance, and monitoring parameter optimization are carried out on the ground, which minimizes safety risks and overcomes the traditional landing. Due to the disadvantage of poor safety and reliabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com