An intelligent choke for natural gas wells

A choke, natural gas technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increasing operating costs, hidden dangers of operating accidents, affecting normal production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

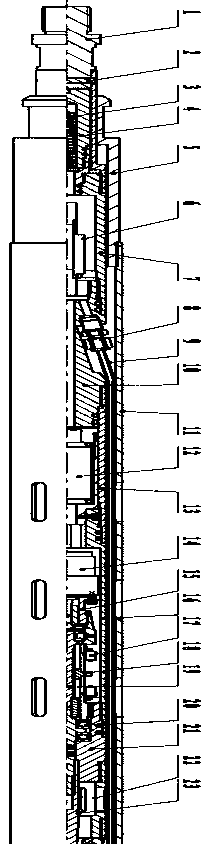

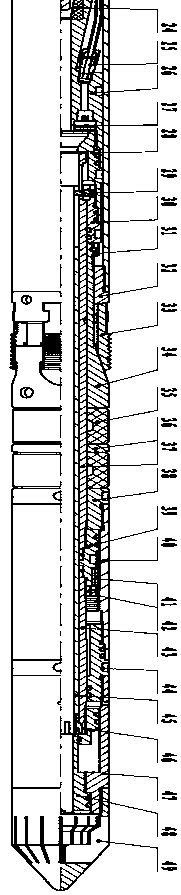

[0023] Such as figure 1 with figure 2 As shown, an intelligent choke device for a natural gas well includes a delivery head 1, a delivery pin 2, a fishing head 5, a lifting outer tube 11, a throttling control adjustment unit, a mechanical anchor setting unit, a setting pin 29 and a sealing ring 30, the feeding head 1 is connected to the upper part of the fishing head 5 through the feeding pin 2, the pulling outer tube 11 is covered with the lower part of the fishing head 5, and the throttling control adjustment unit is connected to the lower part of the feeding head 1 and is located between the fishing head 5 and the lifting head. Pull the inner side of the outer tube 11, and the mechanical anchor setting unit is sequentially connected to the lower part of the throttle control adjustment unit through the setting pin 29 and the sealing ring 30; the throttle control adjustment unit includes a wireless antenna 3, a radome 4, Wireless module and circuit board module 6, circuit b...

Embodiment 2

[0025] Such as figure 1 with figure 2As shown, on the basis of Example 1, the mechanical anchor setting unit includes a lifting retaining ring 31, a slip seat 32, a slip 33, a cone 34, a rubber tube 35, a spacer ring 36, an upper center Tube 37, rubber cartridge seat 38, central tube connector 39, locking cover 40, locking pawl 41, limit ring 42, lower central tube 43, piston 44, release lever 45, sealing body 46, sealing cover 47, setting seal The push rod 48 and the filter body 49, the cone 34 and the lifting retaining ring 31 are all connected to the lower end of the sealing ring 30, and the slip seat 32 and the slip 33 are connected to the outside of the cone 34 sequentially from top to bottom, The lower part of the setting pin 29 is sequentially connected with the upper central tube 37, the central tube connecting body 39 and the lower central tube 43 from top to bottom, and the upper central tube 37 is sleeved with the rubber tube 35, the spacer ring 36 and the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com