Drilling tool flow device for deep water downhole

A deep-water well and diameter technology, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problems of inability to manually put diameter gauges on two-story platforms, high safety risks, low production efficiency, etc. Diameter operation procedures, meet the requirements of tripping, and provide the effect of liquid flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

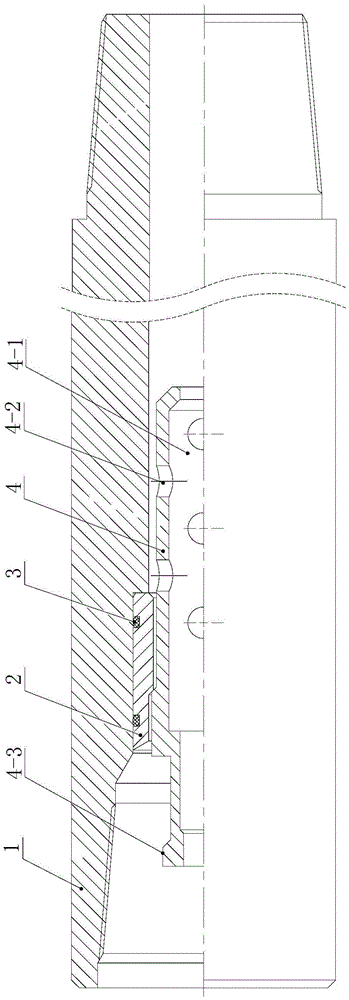

[0019] see figure 1 , deep-water downhole drilling tool drift device, including a fixed nipple 1, a recovery seat 2 and a drift gauge 4 arranged in the fixed nipple, and the seal between the fixed nipple and the recovery seat is sealed by a sealing ring 3. The diameter gauge is axially formed with a through axial circulation hole 4-1, and a plurality of side wall circulation through holes 4-2 are formed on the side wall of the diameter gauge, and one end of the diameter gauge is provided with The boss type fishing head 4-3 is provided with an outer chamfer that is convenient for recovery at the other end of the diameter gauge, so as to play a guiding and correcting role, so that the diameter gauge is not easily stuck in the drilling tool, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com