Zipper lower stopper and quick-release zipper using same

A zipper and bottom stop technology, which is applied in the field of zippers, can solve the problems affecting the basic function of the bottom stop fastening, affecting the operation speed, and affecting the applicability, etc., to achieve rapid disengagement and fastening strength, enhance the lateral tensile strength, Taking into account the effect of splitting and buckling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, this case is described in further detail.

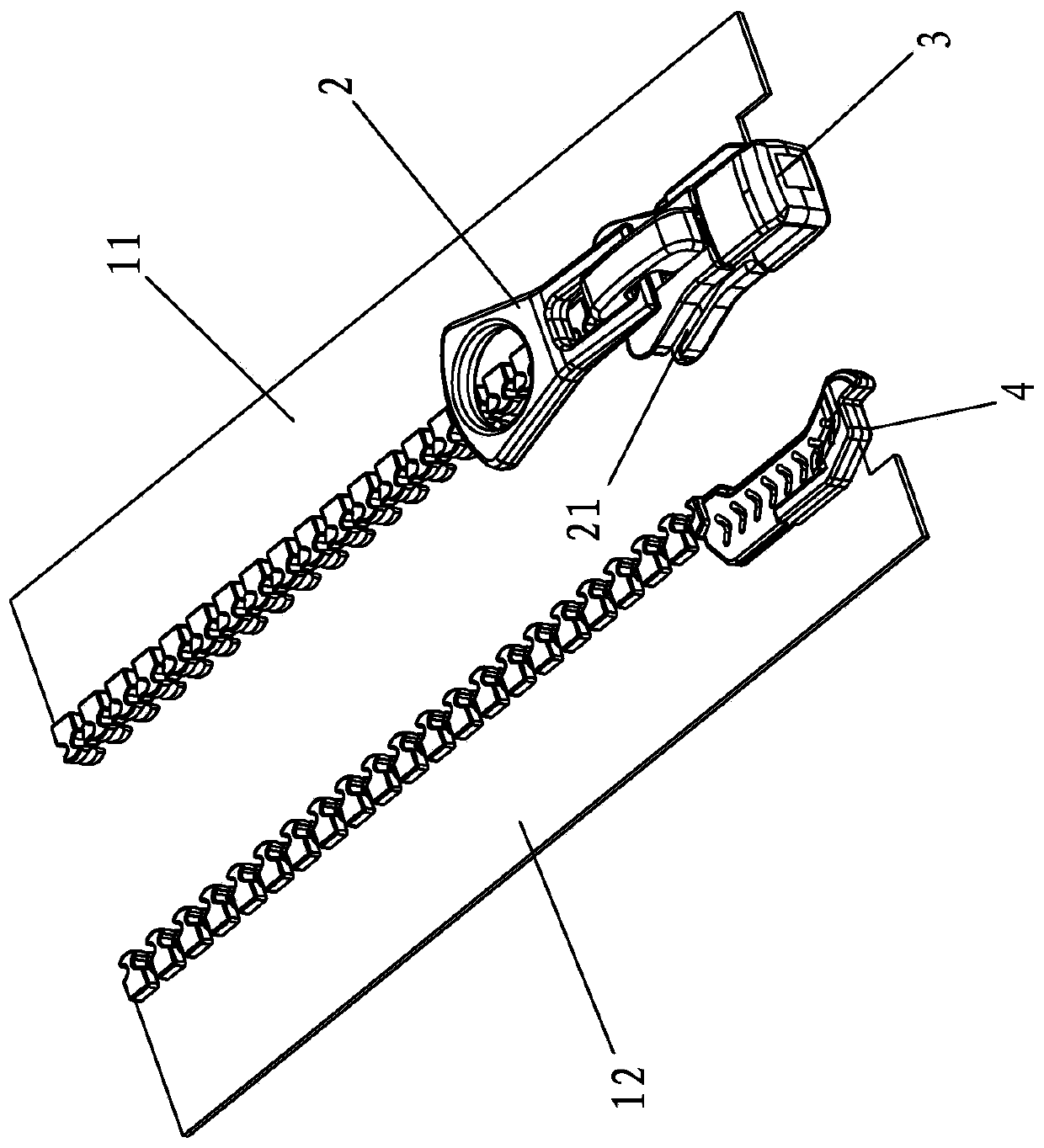

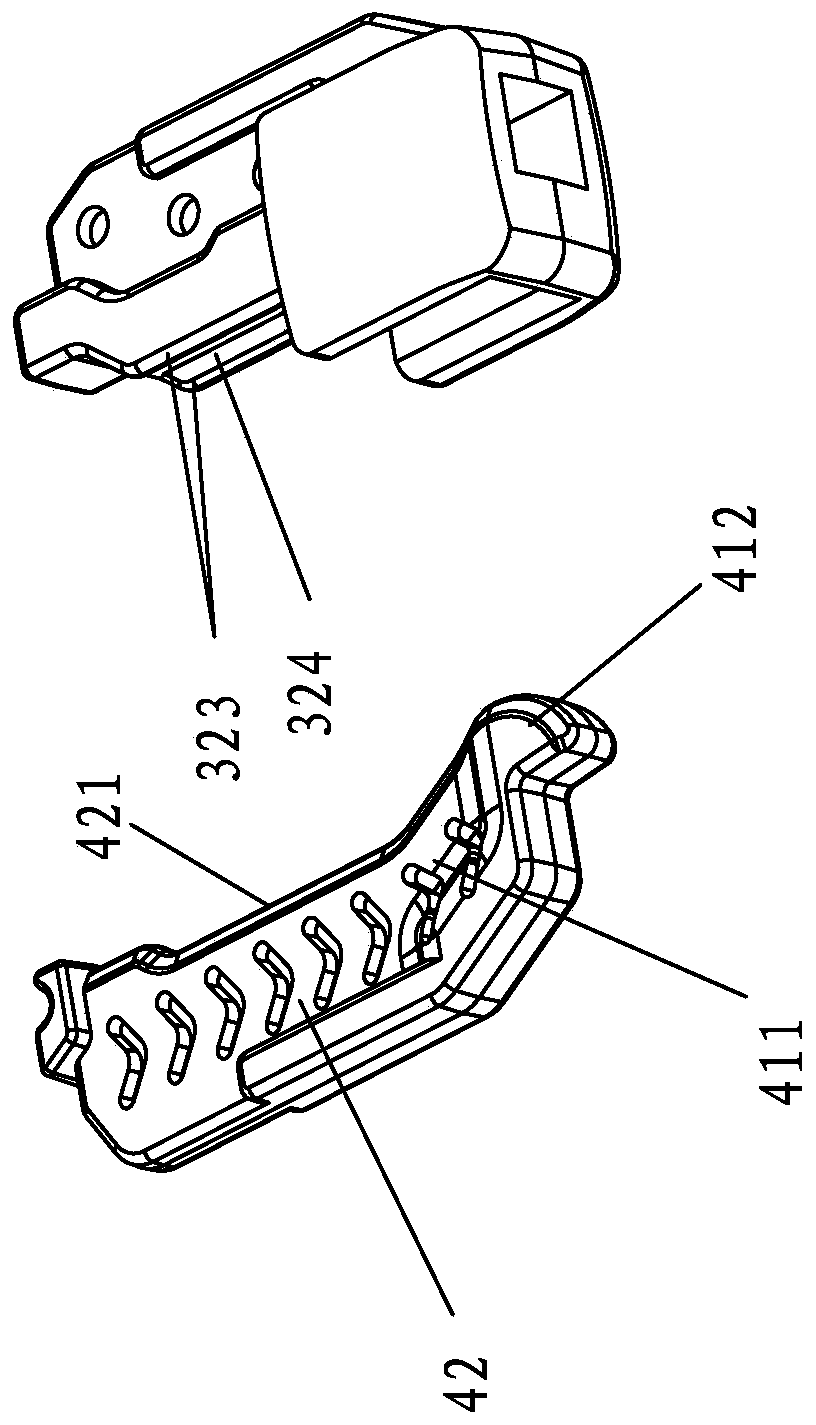

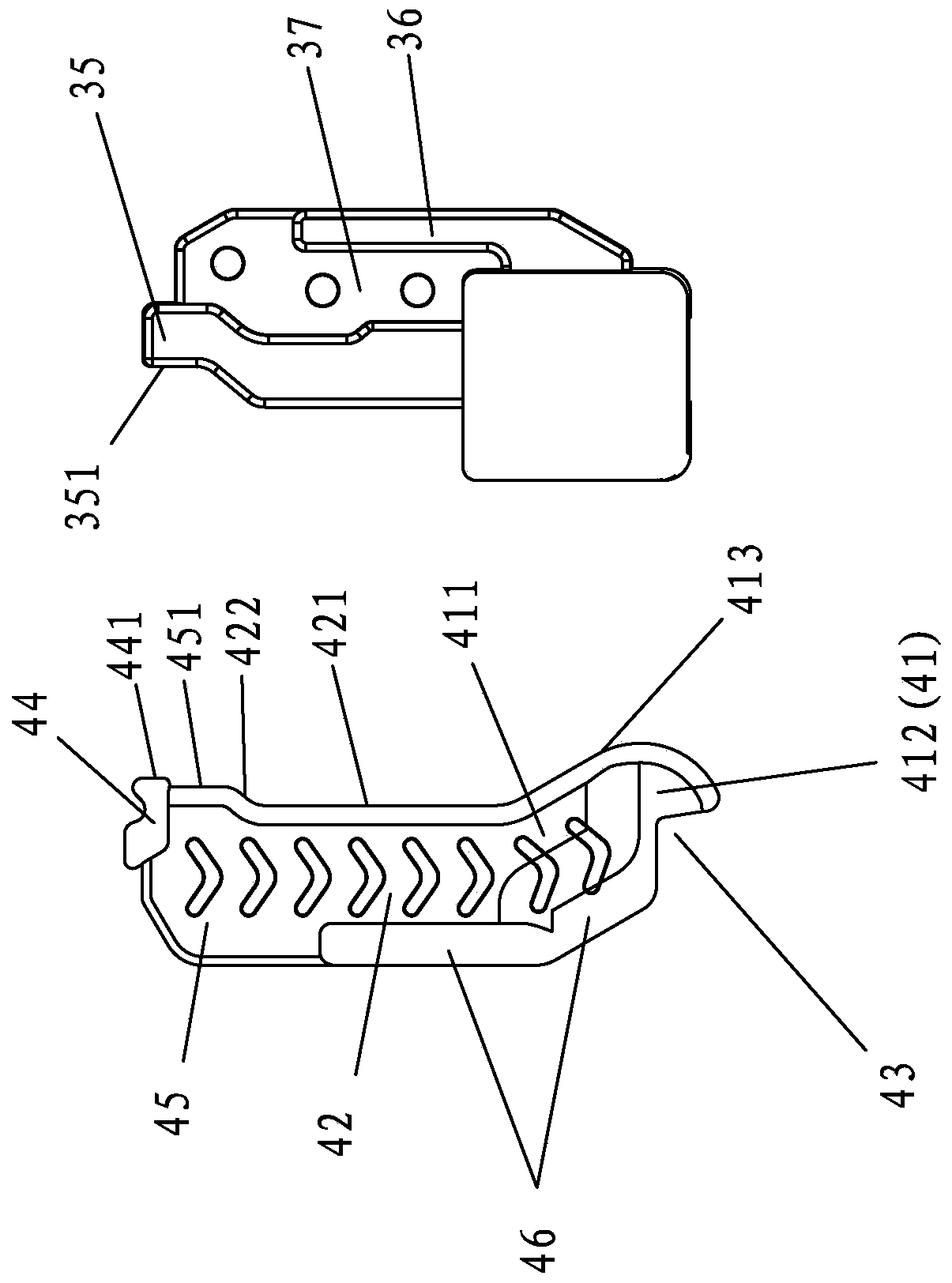

[0037] This case involves a quick release zipper, such as Figure 1-7 As shown, it includes two chain belts, slider 2 and bottom stop. The two chains are respectively a left chain 11 and a right chain 12, and the left chain 11 and the right chain 12 are respectively provided with a row of chain teeth capable of engaging with each other. The bottom stop includes a left stop 3 and a right stop 4, the left stop 3 and the right stop 4 are respectively arranged on the left chain belt 11 and the right chain belt 12 one by one, and the slider 2 is installed on the left chain belt 11 , the slider 2 has upper and lower ship plates, and the two sides of the upper and lower ship plates are respectively provided with a left side side groove and a right side side groove 21, and the slider 2 is installed on the left chain belt 11 through the left side side groove, and the right side The stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com