Conductive silver paste for flexible thin-film solar cell module and preparation method of conductive silver paste

A technology of solar cells and conductive silver paste, which is applied in the field of solar cells, can solve the problem of damage to the comprehensive conductivity of components, and achieve the effects of improving stability and reliability, good wettability, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

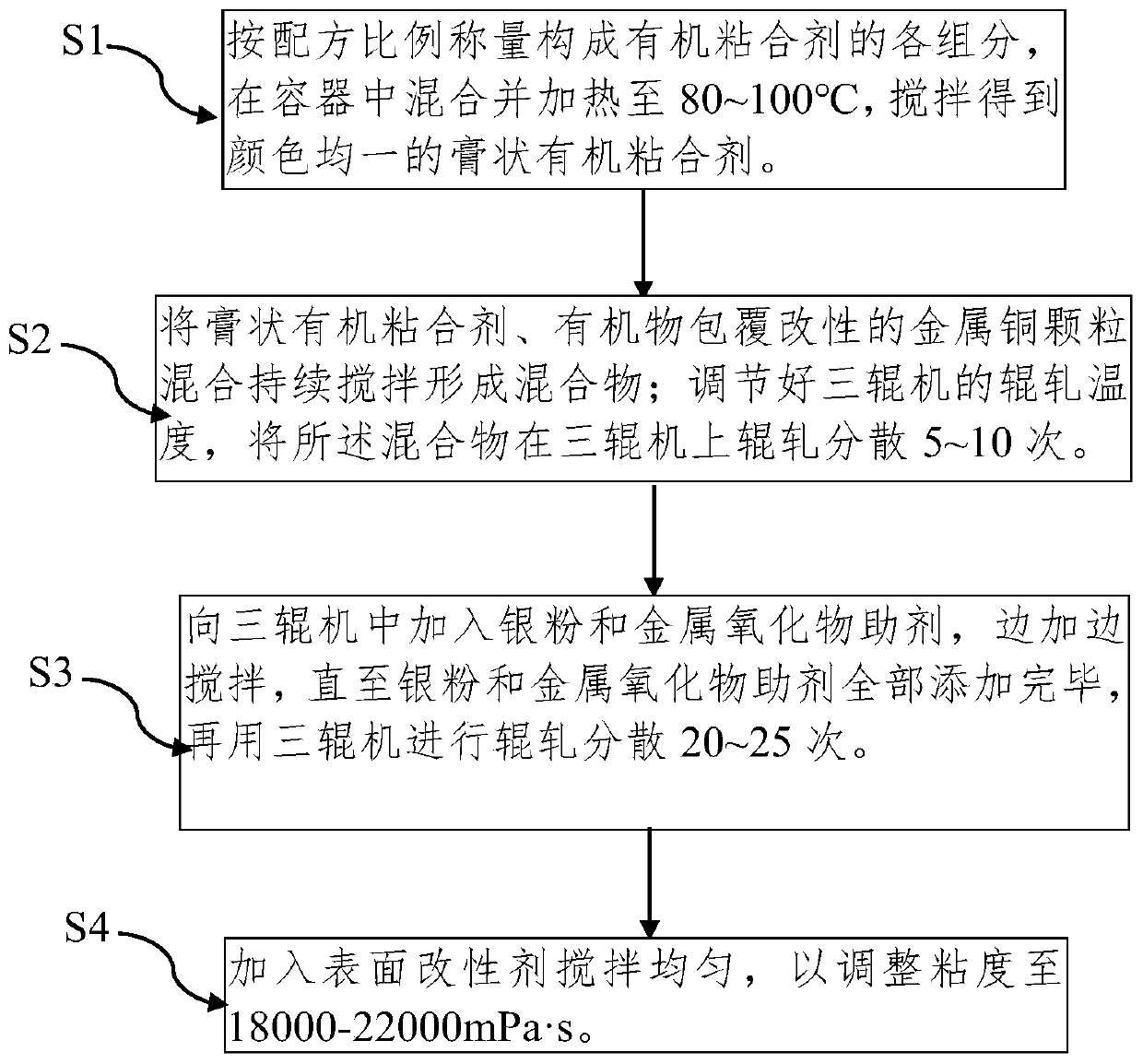

[0040] according to figure 1 Shown, be the preparation method of a kind of flexible thin film solar cell module of the present invention conductive silver paste, it comprises:

[0041] S1: Weigh the components constituting the organic adhesive according to the proportion of the formula, mix them in a container and heat to 80-100°C, and keep stirring to obtain a paste-like organic adhesive with uniform color for later use; it is preferable to use an oil bath to keep the temperature constant Heat to 80-90°C, and stir for 4 hours.

[0042] S2: Mix the paste-like organic binder and organic-coated modified metal copper particles, and continue to stir to form a mixture; adjust the rolling temperature and the rolling gap of the three-roll mill, and place the mixture on the three-roll mill Disperse by rolling for 5-10 times; the preferred rolling temperature is 25-28°C.

[0043] S3: then continuously add silver powder and metal oxide additives in the three-roll machine, stir while a...

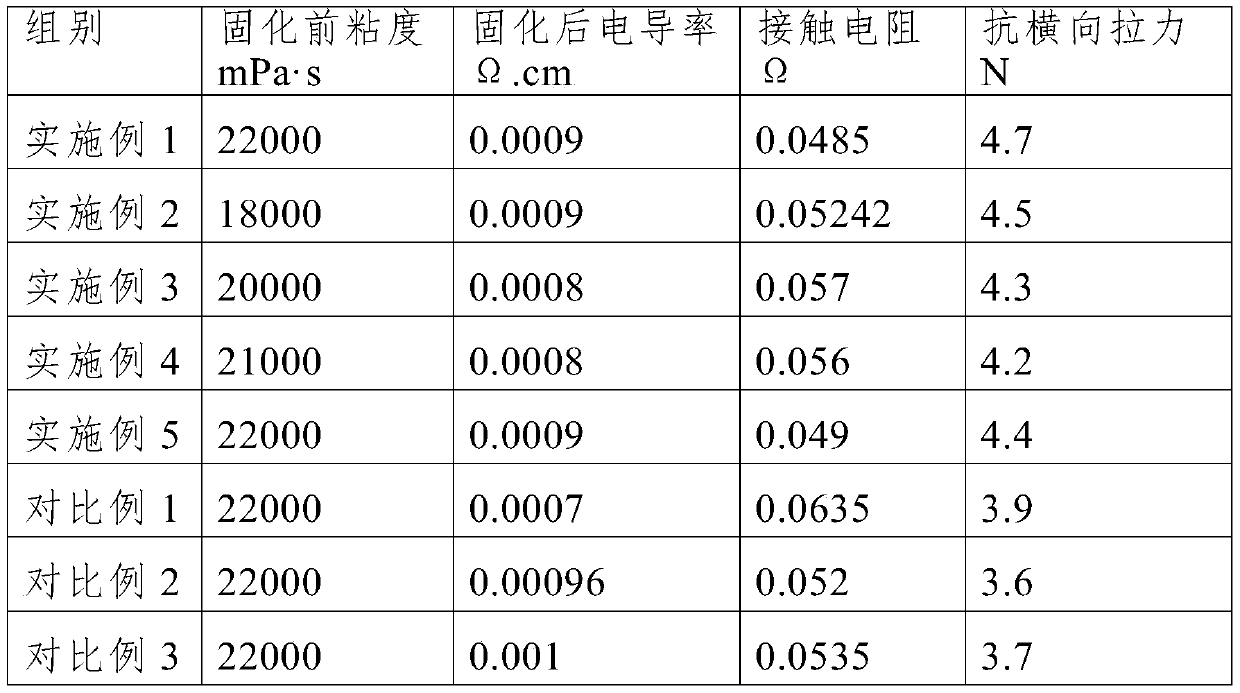

Embodiment 1

[0049] (1) Preparation of organic binder

[0050] Take by weight respectively 20% terpineol, 29% ethylene glycol phenyl ether acetate, 29% diethylene glycol butyl ether, 2% lauryl alcohol ester, 14% rosin, 3% Polypropylene resin and 3% lecithin were uniformly mixed in a beaker, heated to 90° C. in an oil bath at a constant temperature, and stirred continuously for 4 hours to obtain a paste-like organic adhesive with uniform color for future use.

[0051] (2) The preparation of conductive paste is divided into four steps:

[0052] The first step, take by weighing the above-mentioned organic binder that mass percent is 20% and the Cu particle that 2% organic matter is coated with modification, fully stirs evenly in the stainless steel round basin, takes by weighing 75% silver powder (average particle diameter) simultaneously 0.5~3 μm spherical silver powder) and 3% metal oxide doping aid SnO powder (particle size is equivalent to silver powder) in another stainless steel round ...

Embodiment 2

[0059] (1) Preparation of organic binder

[0060] Take by weight respectively 20% terpineol, 29% ethylene glycol phenyl ether acetate, 24% diethylene glycol butyl ether, 2% lauryl alcohol ester, 14% rosin, 3% Polypropylene resin, 5% nitrocellulose, and 3% lecithin were uniformly mixed in a beaker, heated to 90° C. in an oil bath, and kept stirring for 4 hours to obtain a paste-like organic adhesive with uniform color for use.

[0061] (2) The preparation of conductive paste is divided into four steps:

[0062] The first step, take by weighing the above-mentioned organic binder that mass percent is 20% and the Cu particle that 8% organic matter coats modification, fully stir in the stainless steel round basin, weigh 70% silver powder (average particle diameter) simultaneously 0.5-3μm spherical silver powder) and 1% metal oxide doping aid ZnO powder and 1% Y 2 o 3 The powder (the particle size of the auxiliary agent is equivalent to that of silver powder) is stored in another...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com