Internal-bridging connection terminal structure

A technology for connecting terminals and terminals, applied in the direction of connection, clamping/spring connection, and components of connecting devices, etc., can solve the problems of complex lines, difficult to apply multiple wiring modes, etc., and achieve the effect of convenient on-site operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

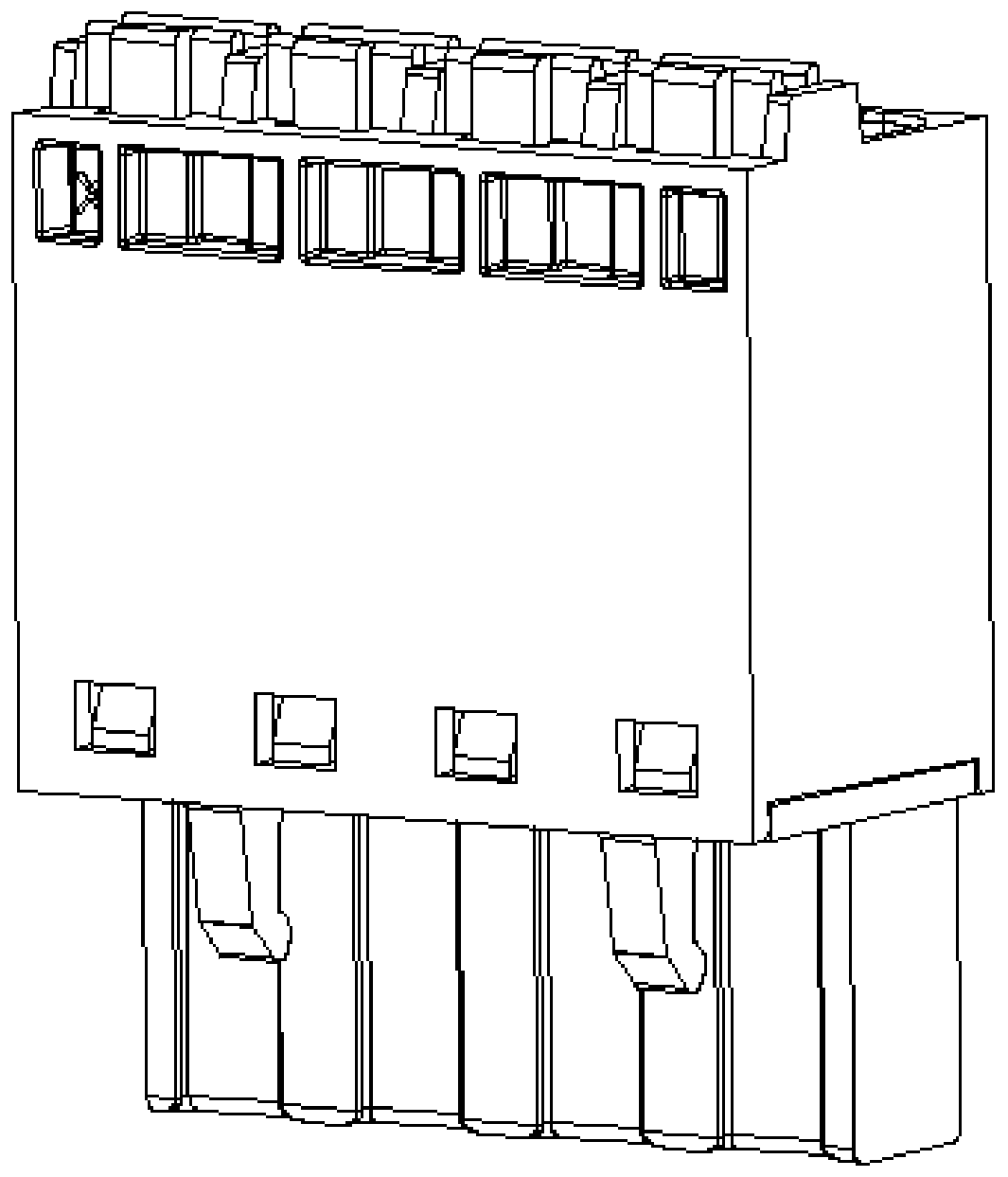

[0044] Embodiment 1: A screw-type internal bridging connection terminal structure, including a first terminal base body 1, the first terminal base body is made of insulating material, and a first clamping component 2 is arranged inside the first terminal base body , the clamping assembly 2 is composed of a bolt 21, a square box 22, and a first bridge structure terminal 23, and the screw 21, the square box 22, and the first bridge structure terminal 23 are arranged inside the first terminal base body 1 in a separated manner Therefore, the bolt 21, the square box 22 and the first bridge structure connection terminal 23 are separate components.

[0045] The first bridge structure connection terminal 23 comprises a first connection terminal 231, a second connection terminal 232 and a bridge structure 233 symmetrically arranged with the first connection terminal 231, wherein the bridge structure 233 is a pair of the first connection terminal 231 and the first connection terminal 231...

Embodiment 2

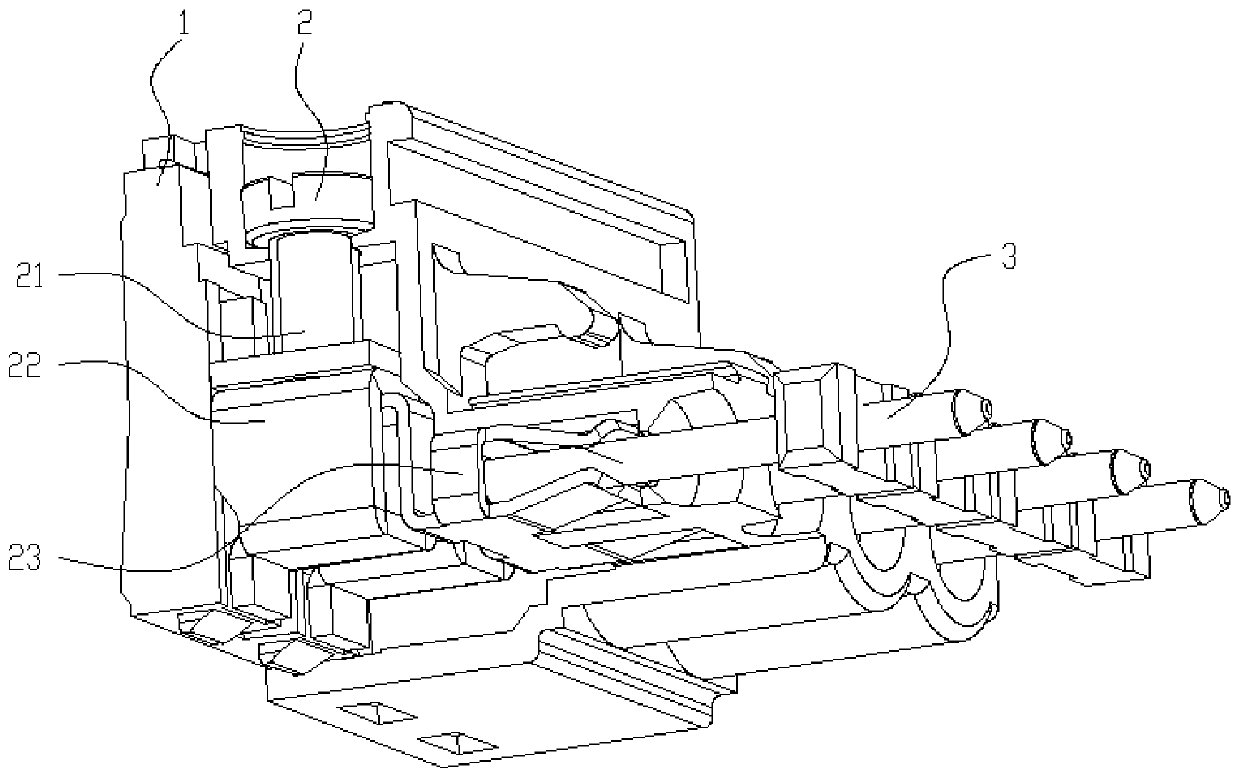

[0048] Embodiment 2: A shrapnel-type internal bridging connection terminal structure, including a second terminal base body 4, the second terminal base body is made of insulating material, and a second clamping component 5 is arranged inside the second terminal base body , the second clamping assembly 5 is composed of a handle 51, an elastic piece 5-2 and a second bridge structure terminal 53, and the handle 51, the elastic piece 52 and the second bridge structure terminal 53 are arranged separately on the second terminal base body 4 Inside, therefore, the handle 51 , the elastic piece 52 and the second bridge structure terminal 53 are separate parts from each other.

[0049] The second bridge structure connection terminal 53 includes a third connection terminal 531, a fourth connection terminal 532 and a second bridge structure 533 arranged symmetrically with the third connection terminal 531, wherein the second bridge structure 533 is a fourth connection of a symmetrical layo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap