Modular marine observation buoy device equipped with automatic propulsion mechanism

An automatic propulsion and modular technology, applied to buoys, ship propulsion, propulsion components, etc., can solve the problems of limited loading area, high installation cost, and inability to splice and use, and achieve the effect of improving structural rationality and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

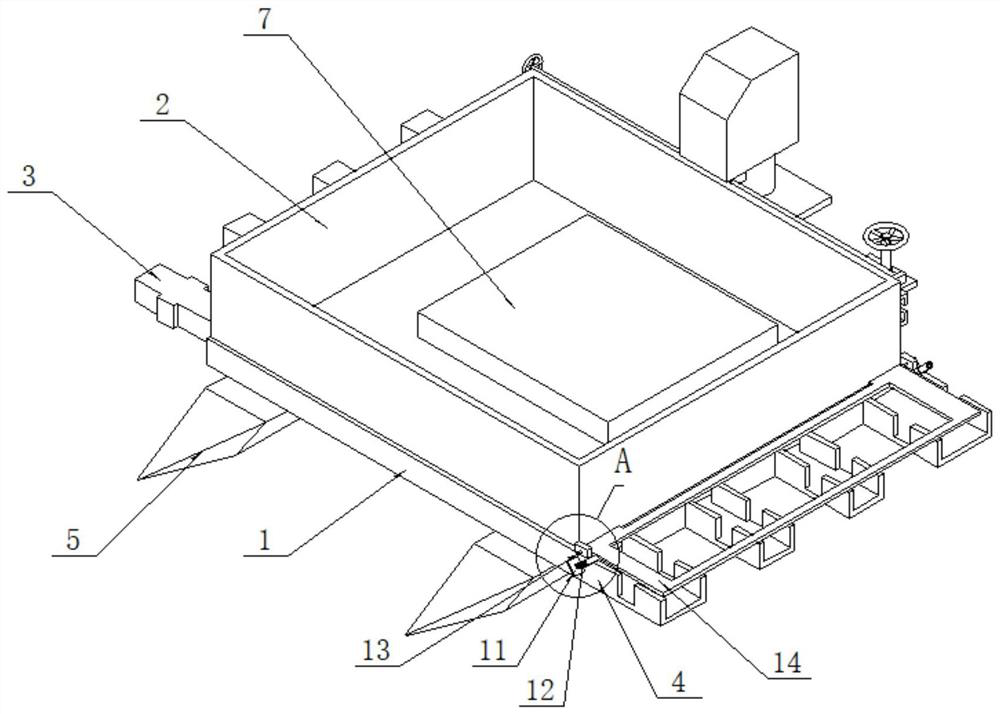

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides the modular marine observation buoy equipment that is installed with automatic propulsion mechanism, comprises base plate 1 and propeller propeller 6; The top chamber 2 of square cavity structure is installed on the top surface of base plate 1; The middle position of top chamber 2 is from bottom to There is a rectangular inner floating body 7 running through it; the bottom surface of the bottom plate 1 is provided with two cone-shaped side floating bodies 5 located on both sides of the inner floating body 7; Left deck 3 and right deck 4; Propeller propeller 6 is positioned at the rear side of top cavity 2 in a vertical manner; Left deck 3 and right deck 4 are all light-weight shell cavity structures, wherein right deck 4 The housing cavity structure is upward, and the housing cavity of the left card base 3 is downward, and a draw rail and a draw groove structure are provided betwee...

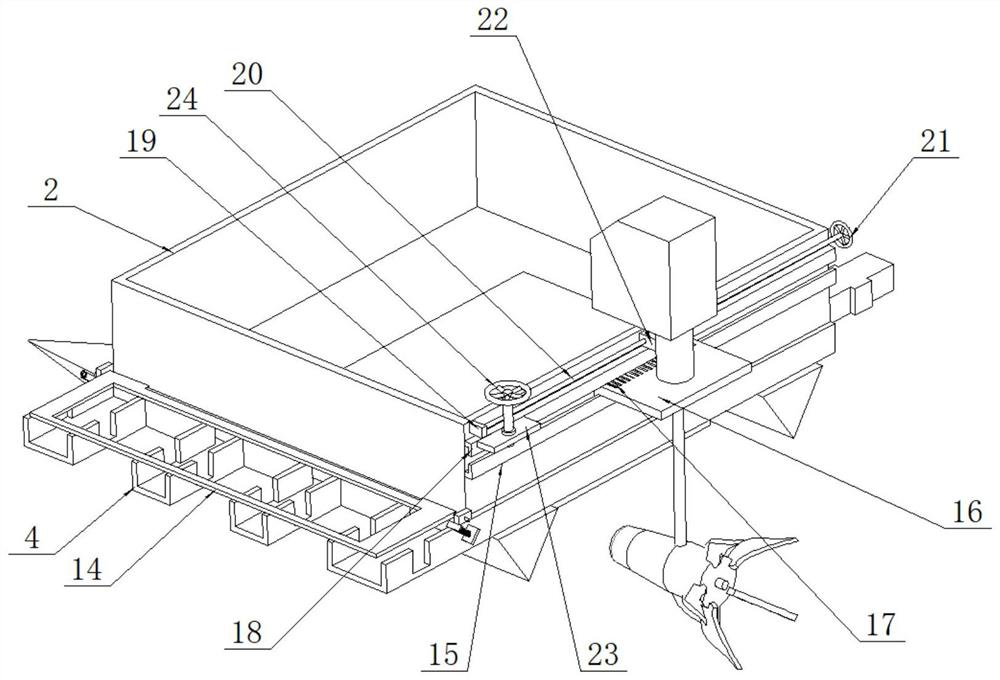

Embodiment 1

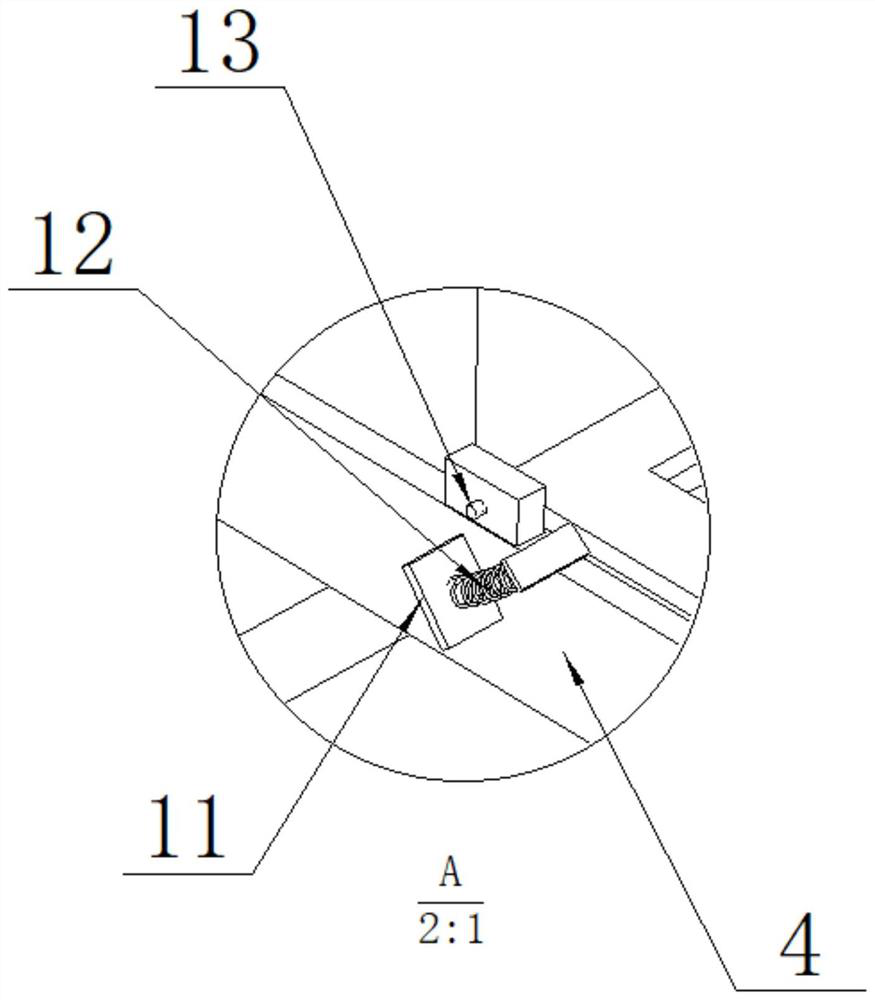

[0035]Embodiment 1: The rear end surface of the top cavity 2 is welded with a lower guide plate 15 and an upper guide plate 18 that can form a guide cavity structure according to the upper and lower corresponding relationship, and the guide cavity formed by the two is slidably fitted with a slide plate 16 that can slide back and forth , the propeller propeller 6 is installed on the slide plate 16 in a vertically penetrating and fixed manner, and the slide plate 16 can be adjusted to slide back and forth. Therefore, the floating body of this structure and the floating body of the same structure use the left card seat 3 and the right card seat on both sides 4. When buckled in use, the combined floating body can be powered by adjusting the propeller propeller 6 on one floating body to reach the middle position; the top surface of the right card seat 4 passes through two hinged seats 13 rotations are fitted with a pressing plate 14 that can be pressed down. Two connecting plates 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com