Quick labeling method and device for stepped holes in three-dimensional model

A technology of 3D models and stepped holes, applied in the direction of design optimization/simulation, etc., can solve problems such as high requirements for engineers, need to improve efficiency, low labeling efficiency, etc., and achieve the goals of improving labeling efficiency, simple and convenient labeling methods, and shortening labeling time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

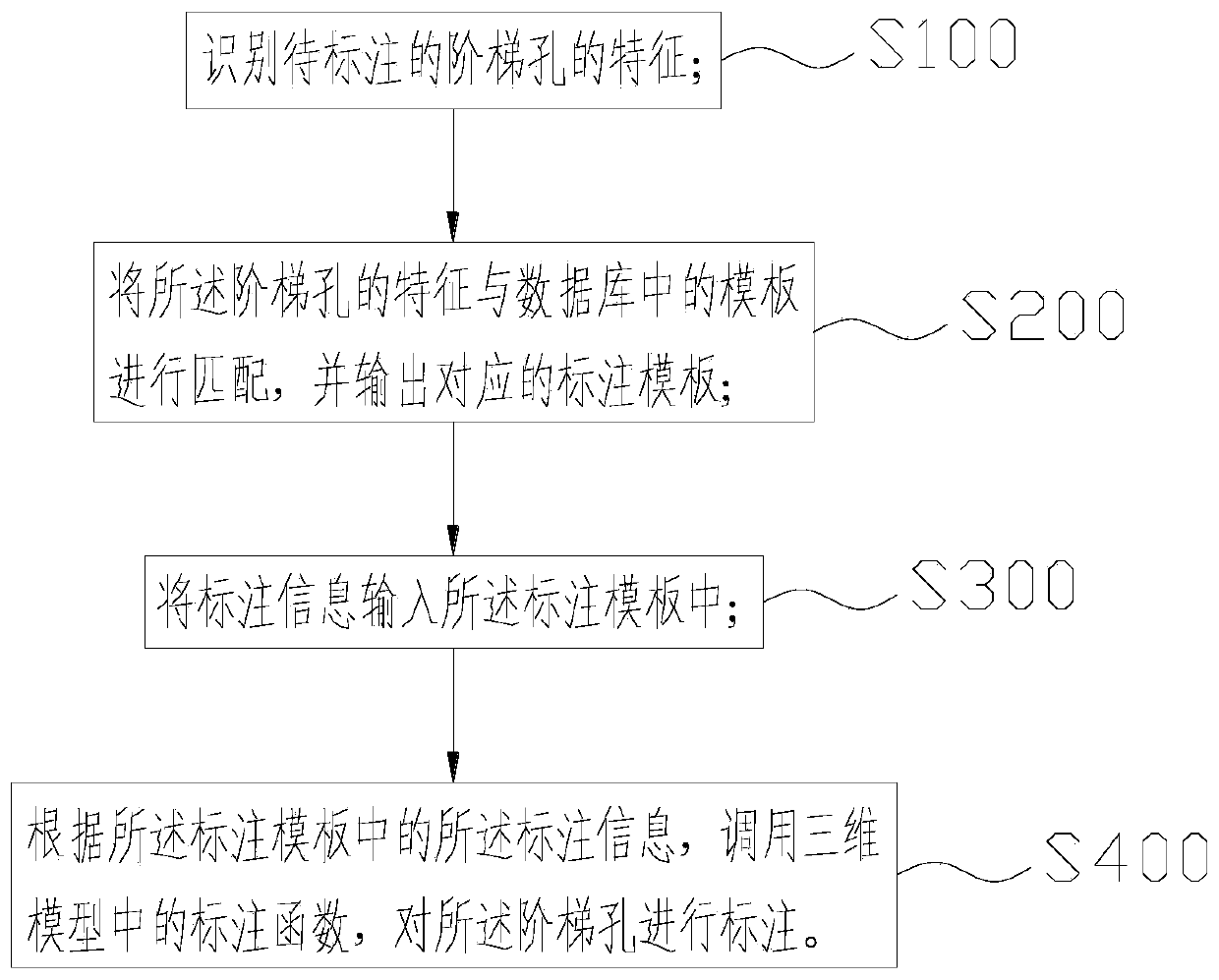

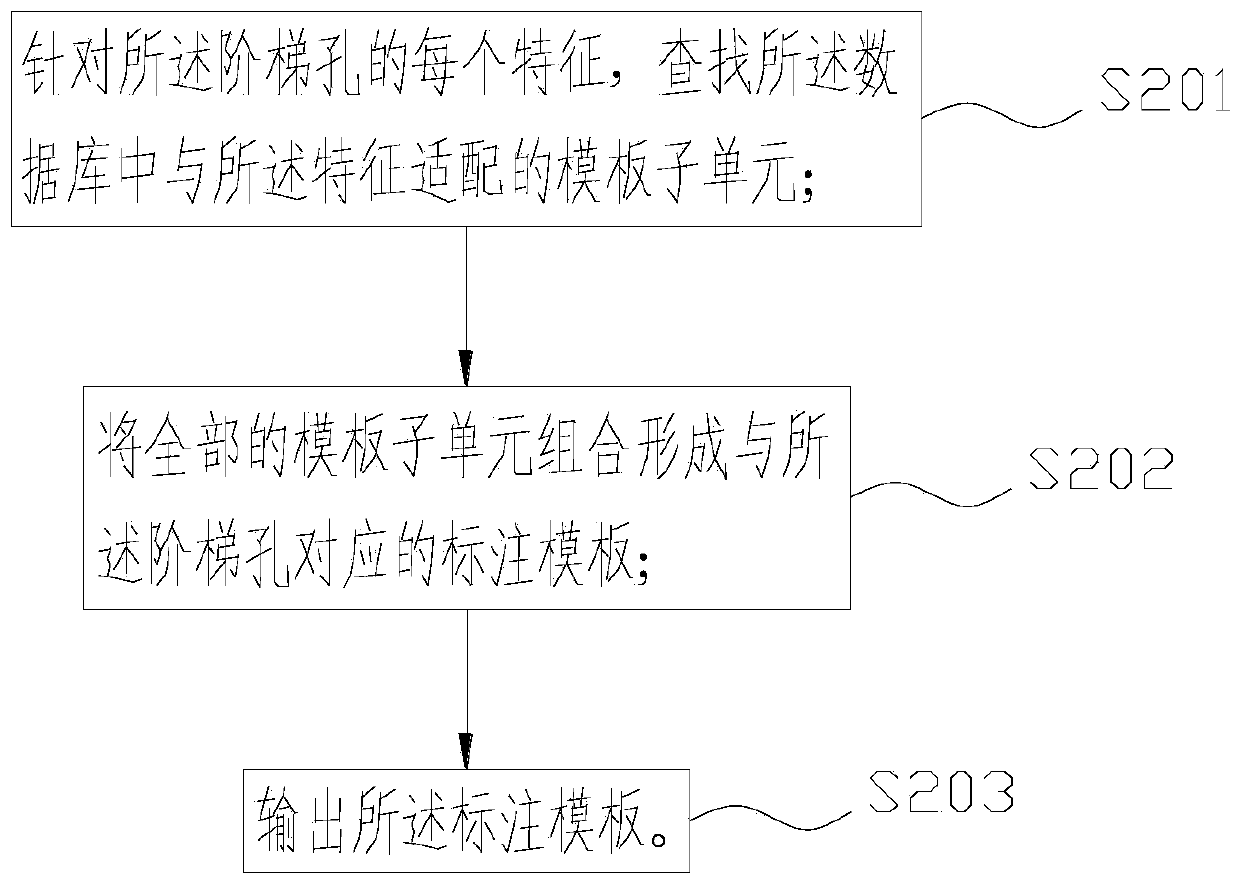

Method used

Image

Examples

Embodiment

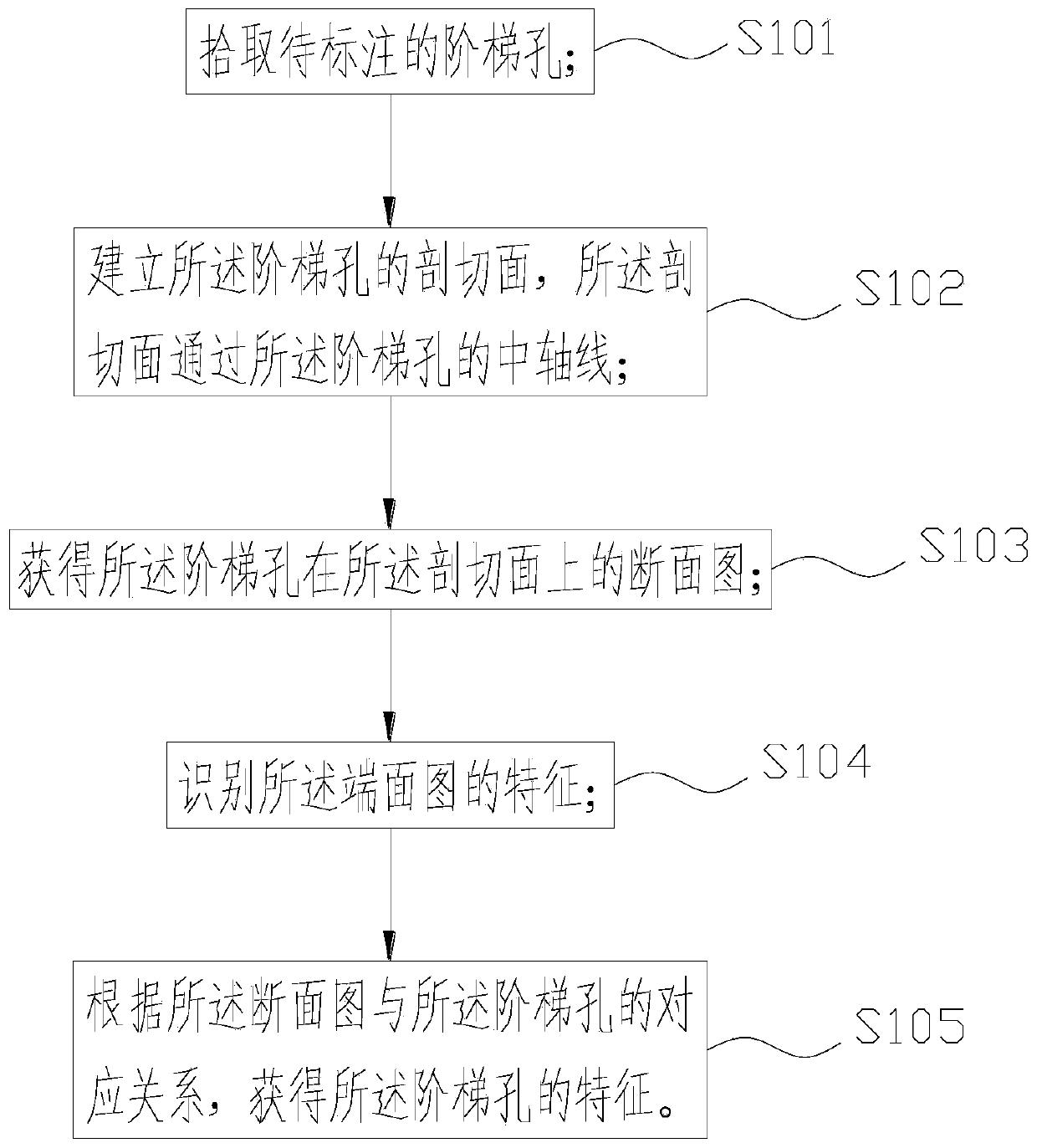

[0106] 1) Pick a stepped hole: You can pick a stepped hole by picking a feature of the stepped hole, for example, select the top edge of the stepped hole, such as Figure 7 shown.

[0107] Also includes the number and feature name of the input feature.

[0108] 2) Create a section plane and obtain a section diagram: it is used to store the marked information later. The section plane passes through the axis of the hole. There is no limit on the surface, but it is necessary to avoid sectioning to the place where the hole is broken.

[0109] 3) Feature recognition: use feature recognition technology to identify the features of the end view, and obtain the features of the stepped holes according to the corresponding relationship between the cross-sectional view and the stepped holes. For example, define the type of a cylindrical surface as 0, the type of a conical surface as 1, the type of a torus as 2, and the type of a fillet as 3. The types of each order form the shape code i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com