An Intelligent Optical Cable Monitoring System for Optical Cable Protection

A monitoring system and optical cable protection technology, which is applied in the direction of optical instrument testing, machine/structural component testing, optical fiber/optical waveguide equipment testing, etc. It can solve problems such as damage, normal life impact, and failure to notify optical cable maintenance personnel in time. Achieve the effect of high statistical degree and convenient integrated management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

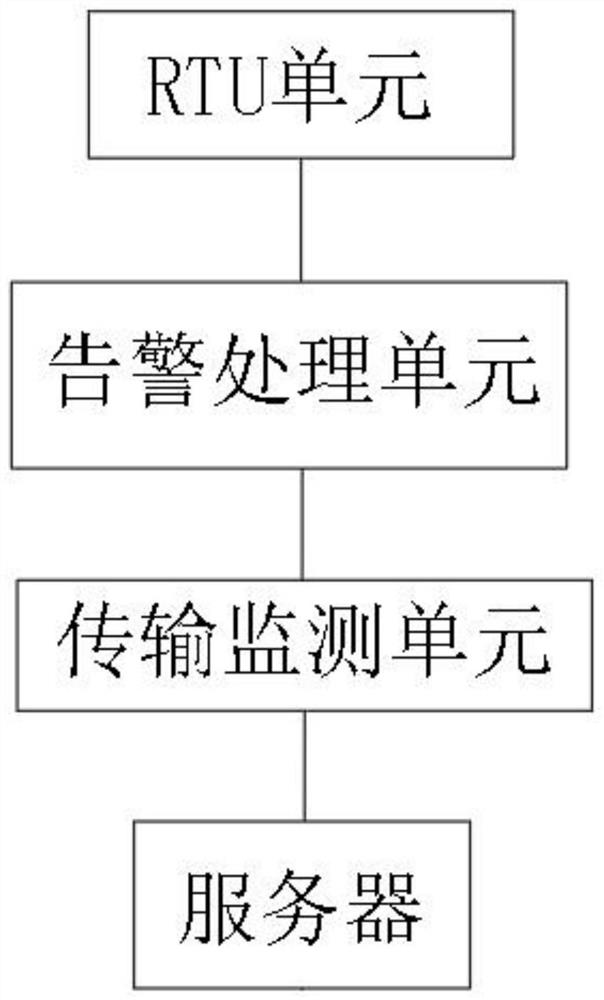

[0064] Such as figure 1 As shown, an intelligent optical cable monitoring system for optical cable protection includes an RTU unit, an alarm processing unit, a transmission monitoring unit, a server, and a retrieval unit;

[0065] Among them, the RTU unit includes an RTU module, an execution module, and a matching switching module. The RTU module is used for terminal detection instruments to collect remote data. The remote data includes optical power data, fault location information, fault time, and monitoring point codes. The execution module is used for Execute the switching of the optical path, the matching switching module is used to retrieve the corresponding backup optical path, and the alarm processing unit is used to perform classification processing according to the fault information. The specific classification processing steps are as follows:

[0066] Step 1: Obtain optical power data, marked as G qin , the optical power damage is divided into three levels, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com