A logistics freight simulation loading system

A logistics and transmission module technology, applied in the field of logistics freight simulation loading system, can solve the problem of unsolved reasonable loading and other problems, and achieve the effect of convenient integrated management, simple and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

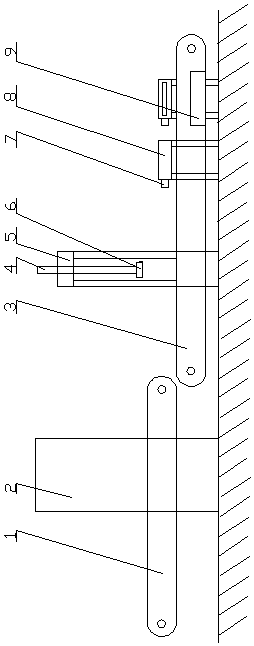

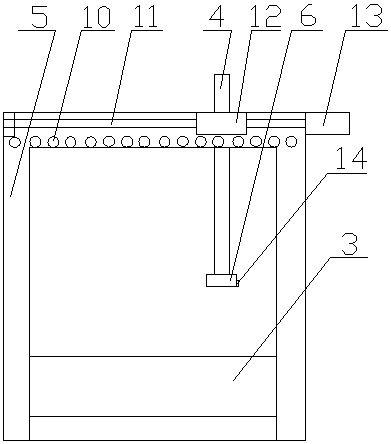

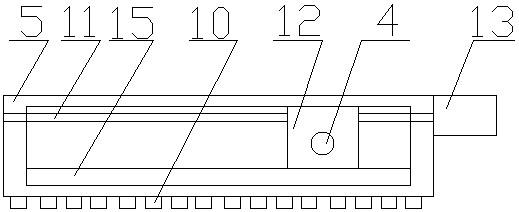

[0034] Embodiment 1: A logistics freight simulation loading system, including a scanning mechanism 2, a control mechanism 19 arranged on the side of the scanning mechanism 2, a marking mechanism arranged at the rear of the scanning mechanism 2, and the scanning mechanism 2 It is connected with the marking mechanism through a transmission module, and a sorting transmission mechanism connected with the control mechanism 19 is arranged at the end of the transmission module.

[0035]The transmission module includes a primary conveyor belt 1 arranged at the scanning mechanism 2 and a secondary conveyor belt 3 arranged at the marking mechanism.

[0036] The scanning mechanism 2 includes a security inspection X-ray machine and a primary transmission belt 1 arranged at the lower part of the security inspection X-ray machine. The primary transmission belt 1 is provided with a plurality of pressure sensors 18 interconnected with a control mechanism 19 for signals.

[0037] The control m...

Embodiment 2

[0042] Embodiment 2: A logistics freight simulation loading system, including a scanning mechanism 2, a control mechanism 19 arranged on the side of the scanning mechanism 2, a marking mechanism arranged at the rear of the scanning mechanism 2, and the scanning mechanism 2 It is connected with the marking mechanism through a transmission module, and a sorting transmission mechanism connected with the control mechanism 19 is arranged at the end of the transmission module.

[0043] The transmission module includes a primary conveyor belt 1 arranged at the scanning mechanism 2 and a secondary conveyor belt 3 arranged at the marking mechanism.

[0044] The scanning mechanism 2 includes a security inspection X-ray machine and a primary transmission belt 1 arranged at the lower part of the security inspection X-ray machine. The primary transmission belt 1 is provided with a plurality of pressure sensors 18 interconnected with a control mechanism 19 for signals.

[0045] The control ...

Embodiment 3

[0051] Embodiment 3: A logistics freight simulation loading system, including a scanning mechanism 2, a control mechanism 19 arranged on the side of the scanning mechanism 2, a marking mechanism arranged at the rear of the scanning mechanism 2, and the scanning mechanism 2 It is connected with the marking mechanism through a transmission module, and a sorting transmission mechanism connected with the control mechanism 19 is arranged at the end of the transmission module.

[0052] The transmission module includes a primary conveyor belt 1 arranged at the scanning mechanism 2 and a secondary conveyor belt 3 arranged at the marking mechanism.

[0053] The scanning mechanism 2 includes a security inspection X-ray machine and a primary transmission belt 1 arranged at the lower part of the security inspection X-ray machine. The primary transmission belt 1 is provided with a plurality of pressure sensors 18 interconnected with a control mechanism 19 for signals.

[0054] The control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com