Mine car monitoring device and system

A monitoring device and mine car technology, which is applied in the direction of test/monitoring control system, general control system, control/adjustment system, etc., can solve the problem of inaccurate mine car data, wrong diagnosis results, and inability to analyze the use of various parts of the vehicle conditions and other issues to improve diagnostic accuracy and avoid mismatching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

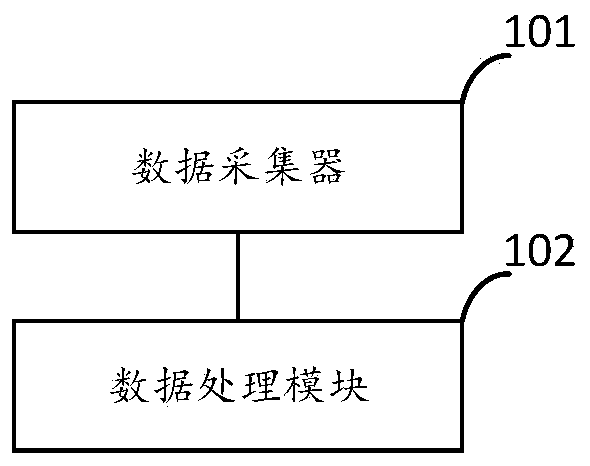

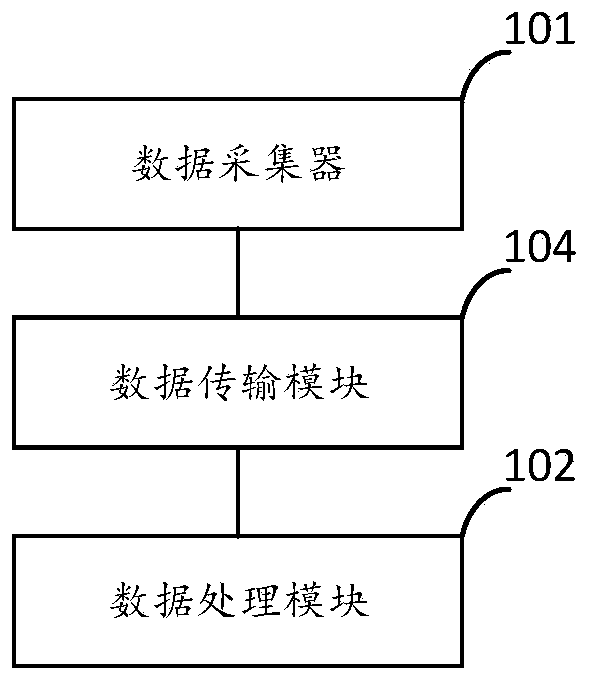

[0037] refer to figure 1 A schematic diagram of a mine car monitoring device is shown, which includes a connected data collector 101 and a data processing module 102 .

[0038] The data collector 101 is used to collect the real-time data of the mine car parts, and sends the real-time data to the data processing module 102, wherein the real-time data includes at least one of the following data of the mine car: lifting times, real-time temperature, pressure and vibration data.

[0039] In a specific implementation manner, the data collector 101 collects real-time data of each component of the mine car, wherein the real-time data may also include the cooling circuit temperature of the mine car in addition to the lifting times, real-time temperature, pressure and vibration data signal, oil rail pressure signal, engine speed signal, vehicle speed signal, cooling fan operation signal and the set controller ERROR status signal, etc., the controller includes such as engine controller...

Embodiment 2

[0062] refer to Figure 4 The schematic diagram of a mining vehicle monitoring system shown includes the mining vehicle monitoring device 401 of the first embodiment, and also includes a control server 402 connected to the mining vehicle monitoring device 401 .

[0063] The control server 402 is used to receive the analysis result uploaded by the mine car monitoring device 401, and generate a mine car maintenance operation instruction corresponding to the analysis result.

[0064] In the above-mentioned system that present embodiment provides, collect the real-time data of mine car parts by setting data collector 101, wherein real-time data includes at least one of following: real-time temperature, number of lifts, pressure and vibration data, and real-time data Send it to the data processing module 102; then the data processing module 102 analyzes the real-time data of the mine car parts in the preset period, and obtains the status information, fault information and maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com