Cloud platform machine room dustproof heat cooling system

A technology of cooling system and cloud platform, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as position and quantity adjustment that cannot be dissipated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

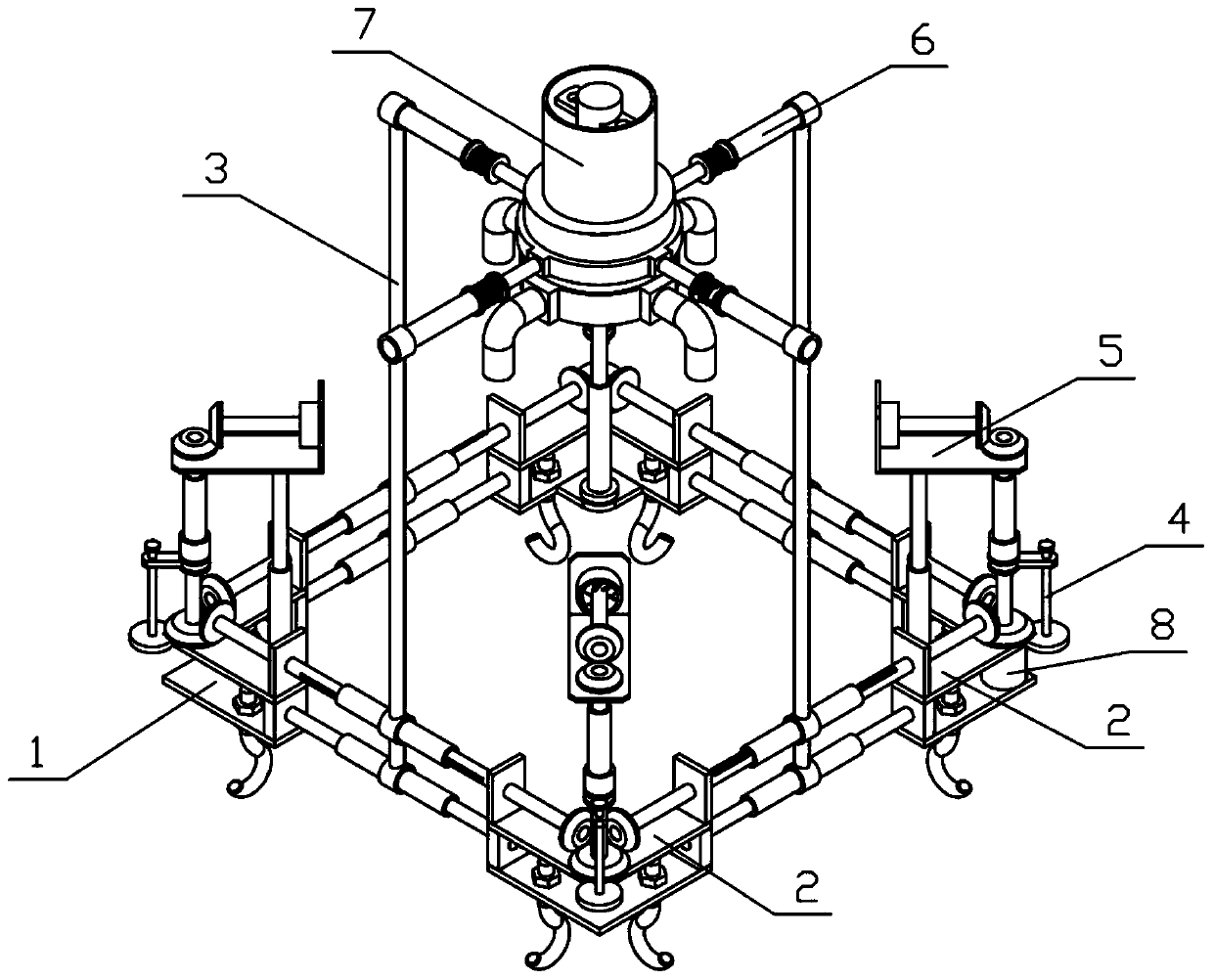

[0032] Combine below Figure 1-10Describe this embodiment, a dust-proof and heat-dissipating system for a cloud platform machine room, including a mounting bracket 1, a transmission bracket 2, a connecting bracket 3, an adjustment mechanism 4, a heat dissipation mechanism 5, a support bracket 6, an air outlet mechanism 7, and a drive motor 8. There are multiple mounting brackets 1, and connecting brackets 3 are threadedly connected between multiple mounting brackets 1, and transmission brackets 2 are fixedly connected to each mounting bracket 1, and multiple transmission brackets 2 are connected by connecting brackets. 3 transmission connection, each transmission bracket 2 is connected with an adjustment mechanism 4, each transmission bracket 2 is slidably connected with a heat dissipation mechanism 5, and the lower end of each heat dissipation mechanism 5 is fixedly connected to the corresponding installation bracket 1, each The adjustment mechanism 4 controls the transmissio...

specific Embodiment approach 2

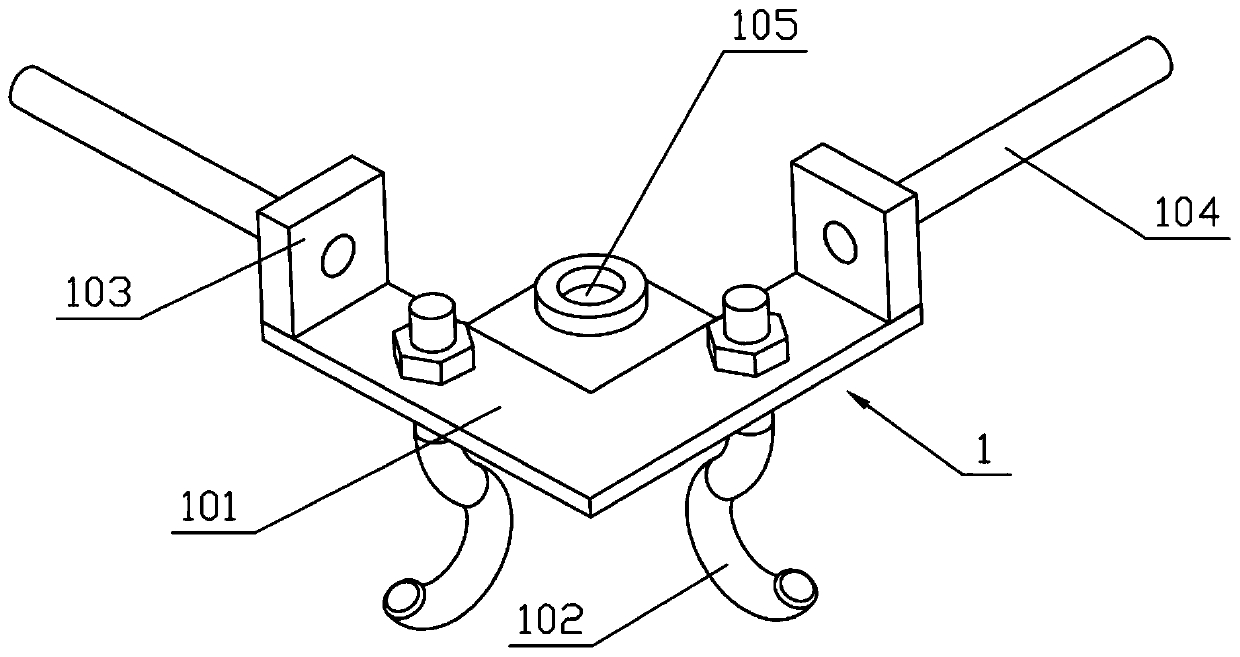

[0034] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the installation bracket 1 includes the installation base plate I101, the anchor bolts 102, the installation side plate 103, the sliding column 104 and the installation base plate II105, and the installation base plate I101 is connected with multiple Two anchor bolts 102 are fixedly connected with installation side plates 103 on both sides of the installation base plate I101, the two installation side plates 103 are fixedly connected with sliding columns 104, and the installation base plate I101 is fixedly connected with the installation base plate II105.

specific Embodiment approach 3

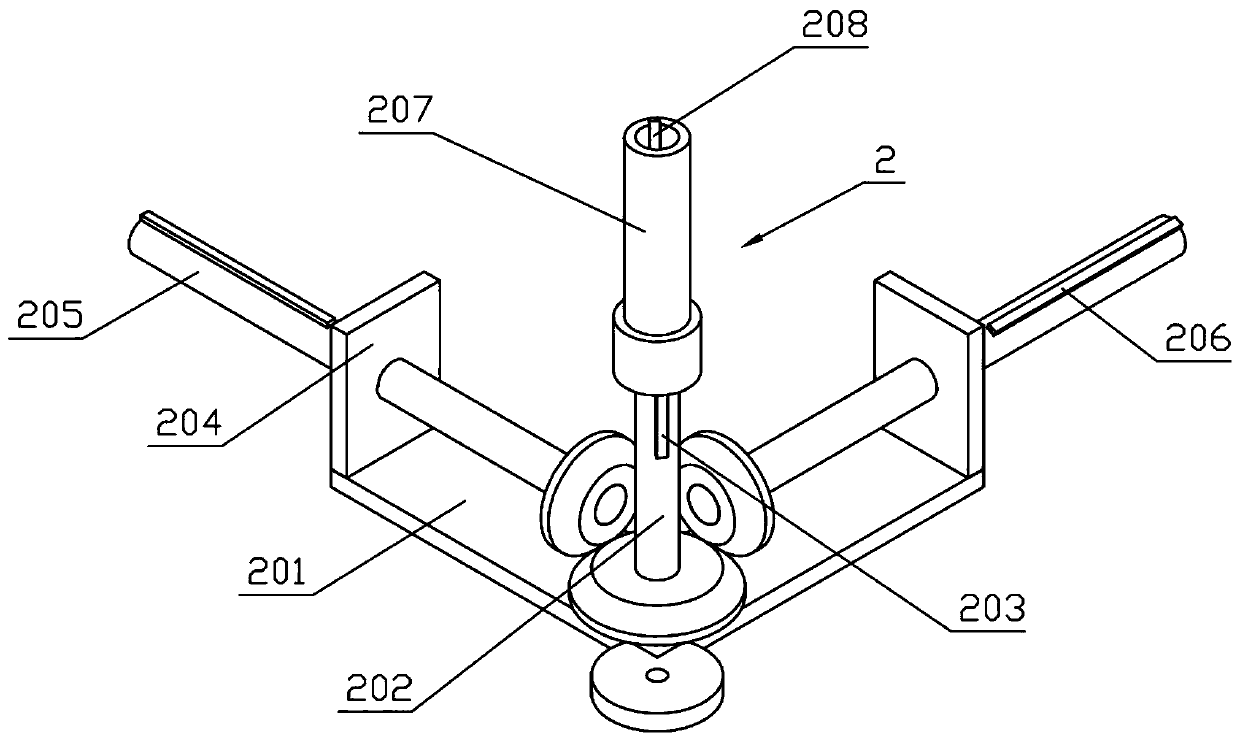

[0036] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the transmission bracket 2 includes a transmission bottom plate 201, a transmission shaft I 202, a connection key I 203, a transmission side plate 204, a transmission shaft II 205, a connection key II 206, and a transmission cylinder 207 and keyway I208, the transmission base plate 201 is rotatably connected to the transmission shaft I202, the transmission shaft I202 is fixedly connected to the connection key I203, both sides of the transmission base plate 201 are fixedly connected to the transmission side plate 204, and both transmission side plates 204 are rotated The transmission shaft II 205 is connected, the two transmission shafts II 205 are fixedly connected with the connection key II 206, the upper end of the transmission shaft I 202 is connected with the transmission cylinder 207 in rotation, the transmission cylinder 207 is provided with a keyway I 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com