Geological exploration drilling quality detection method

A quality detection method and geological exploration technology, applied in neural learning methods, image data processing, image enhancement and other directions, to achieve the effect of improving efficiency, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

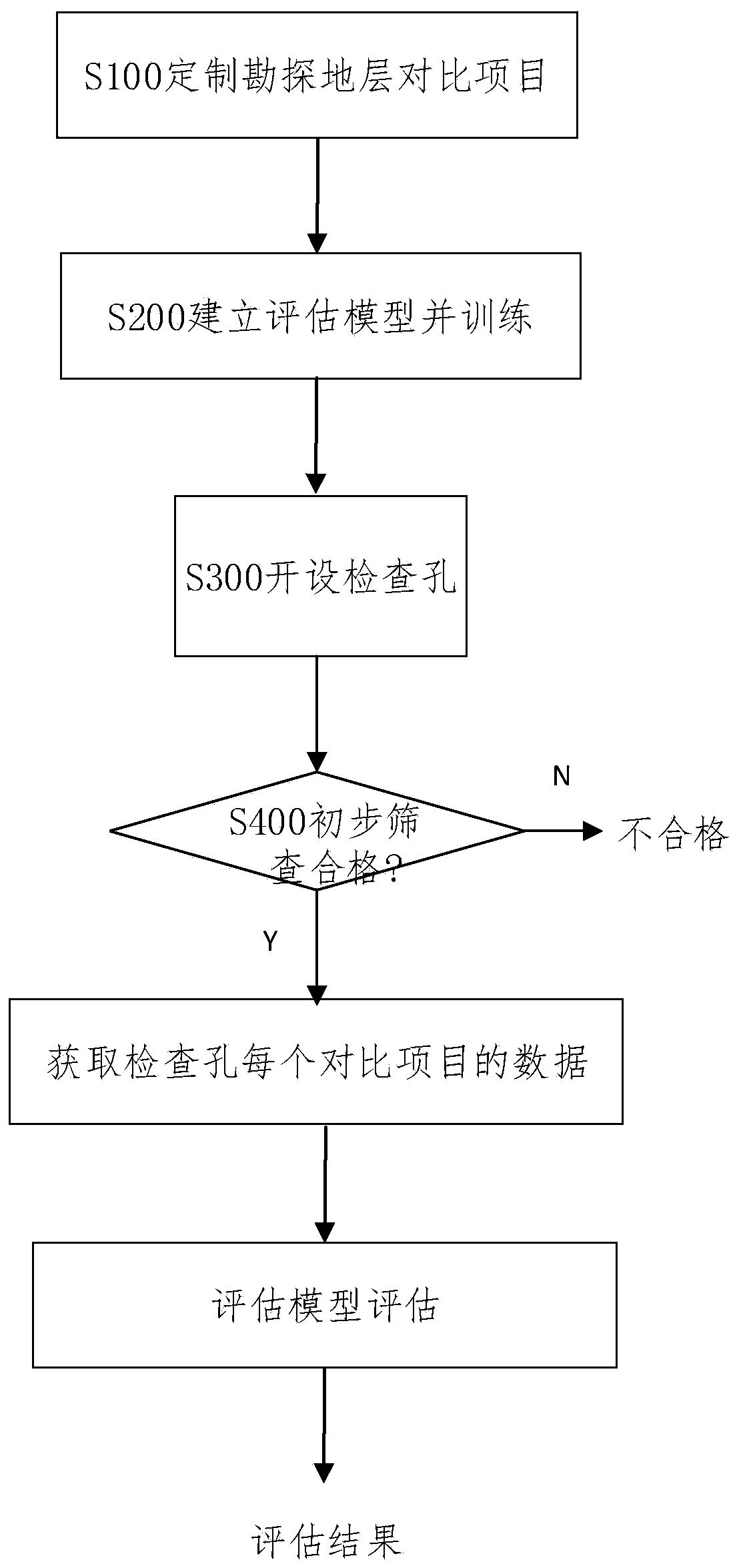

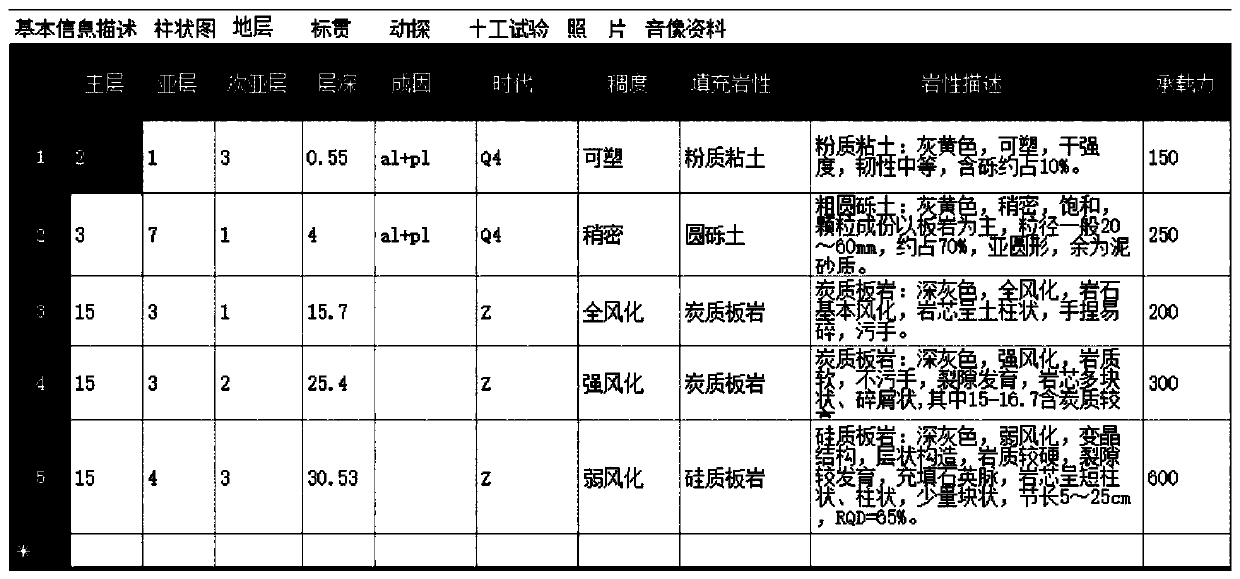

[0057] The invention provides a set of drilling quality detection method based on quick comparison between the inspection hole and the original geological exploration drilling stratum. The evaluation model is built in the geological exploration intelligent management platform (PC terminal web page, mobile phone APP), and the user can check it according to the technical requirements in advance. Compile / customize the drilling quality inspection standard, then select the drilling (original drilling) and inspection hole to be inspected, and quickly check the original drilling and inspection hole exploration stratum through software operation to judge the exploration quality of the original drilling.

[0058] 1. Customize the exploration stratum comparison project according to the exploration technical requirements.

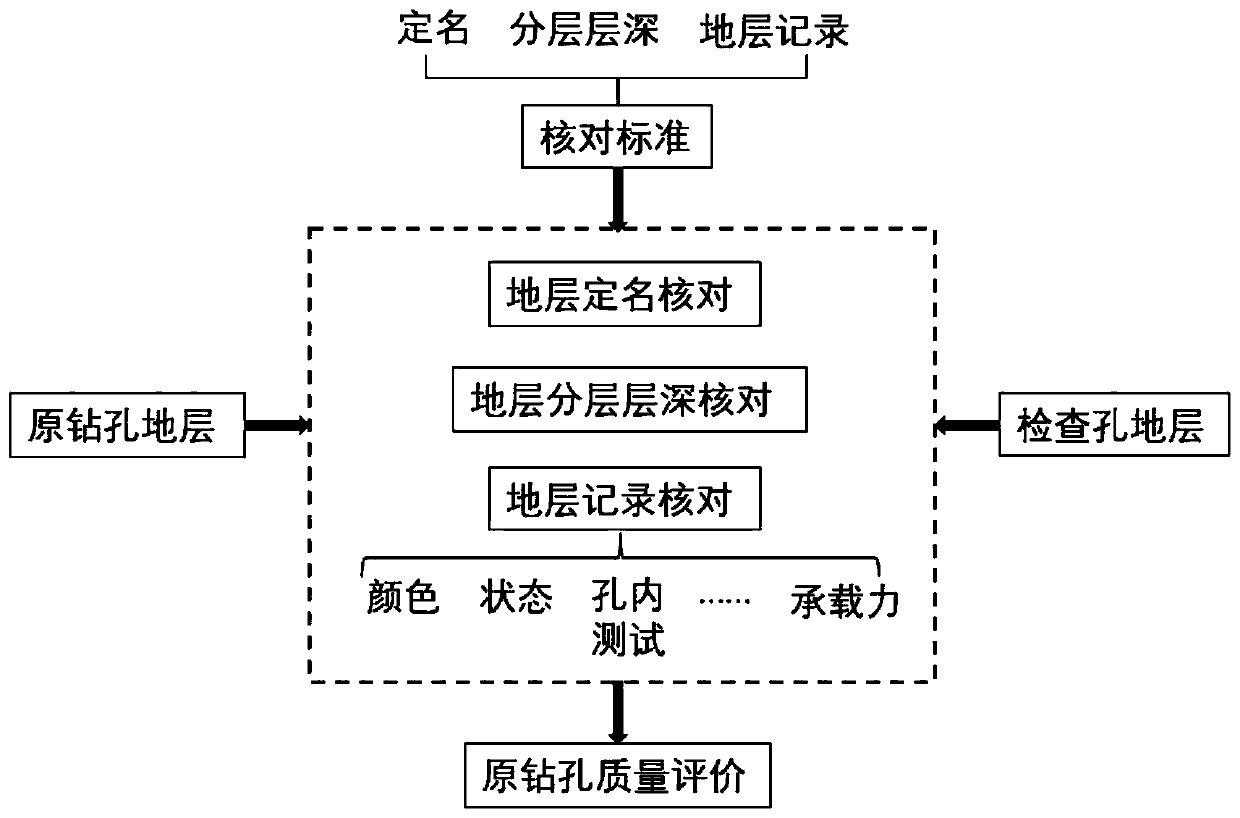

[0059] combine figure 2 , the stratum check standard can be subdivided into three main standards of stratum naming, stratum stratification and stratum record, and th...

Embodiment 2

[0069] 1. Customize the exploration stratum comparison project according to the exploration technical requirements.

[0070] The stratum check standard is subdivided into three main standards of stratum naming, stratum stratification and stratum record, and the scores can be set for the three main standards. The total score of the stratum check standard is set to 100 points, the stratum naming standard score can be set at 30 points, the stratum layering standard can be set at 30 points, and the stratum recording standard can be set at 40 points. The three main standards can also be subdivided into detailed standards, such as stratum naming can be subdivided into main categories, subcategories, etc., and the standard scores are decomposed accordingly.

[0071] 2. Establish and train an evaluation model based on the comparison items.

[0072] The evaluation model can be operated through software (can be carried out on the PC or APP of the geological exploration management platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com