Method for directly distributing airships based on airship hangar with top capable of being opened and closed

An airship and boat garage technology, applied in the field of aerostats, can solve the problems of heavy maintenance workload, being easily affected by ground wind, and limited release conditions, so as to reduce maintenance workload, shorten release time, and improve release conditions. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

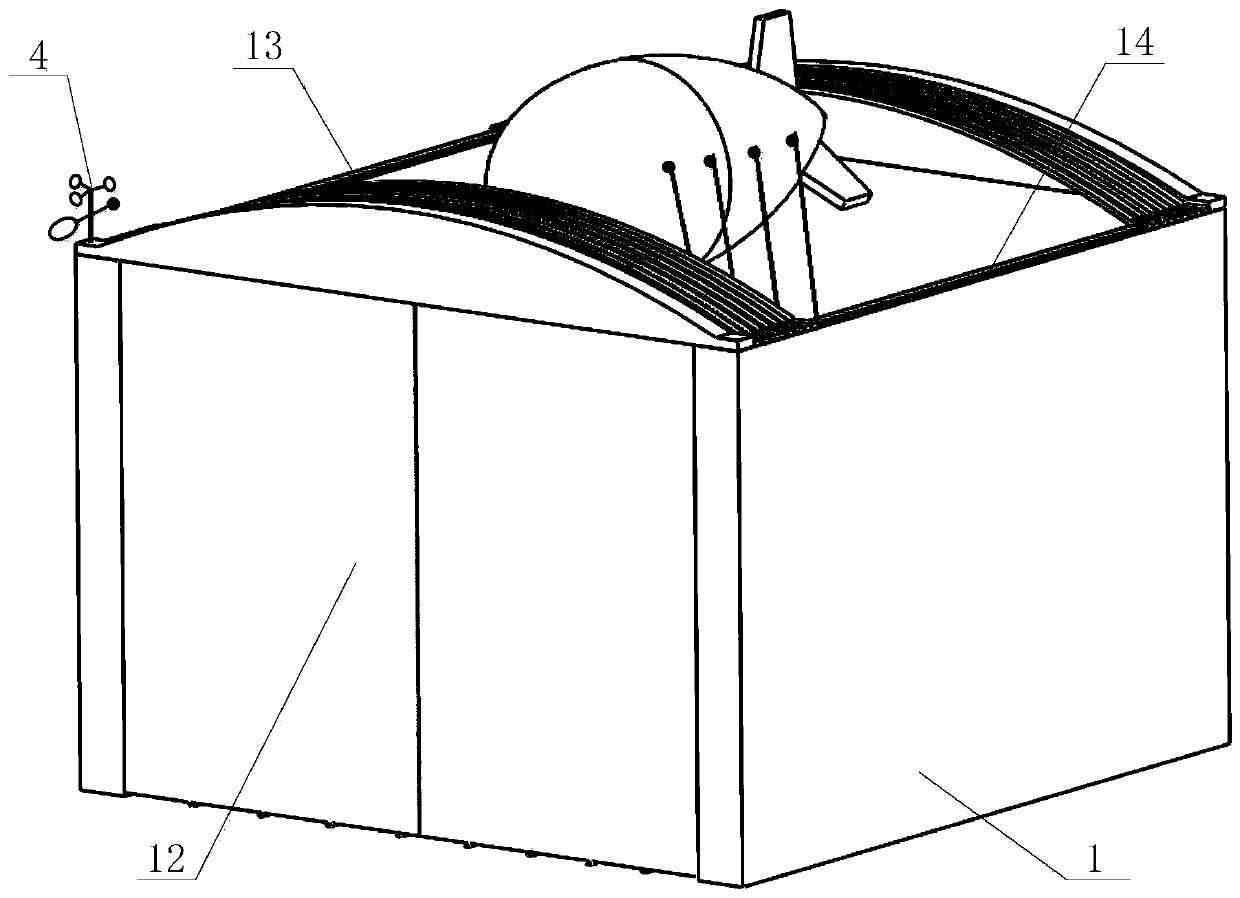

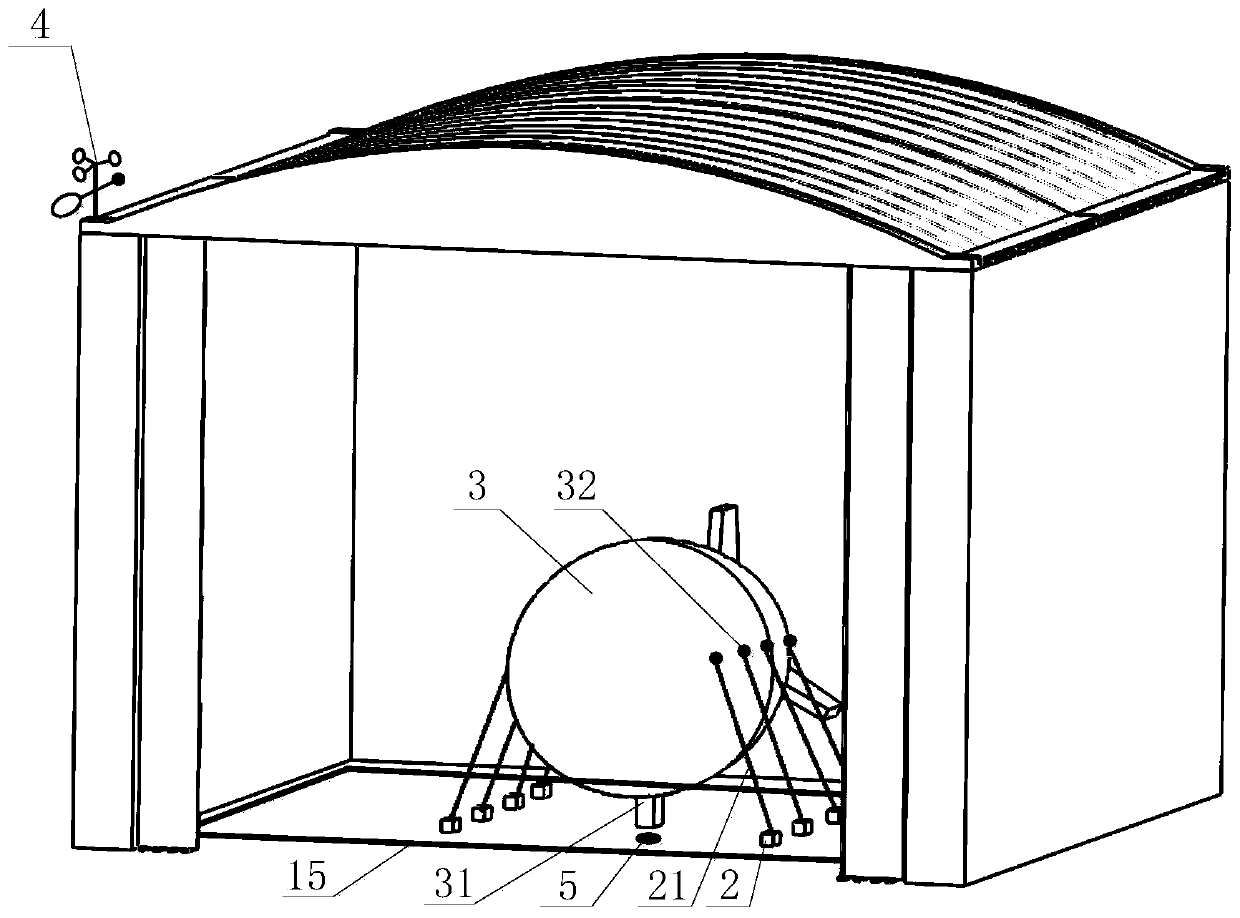

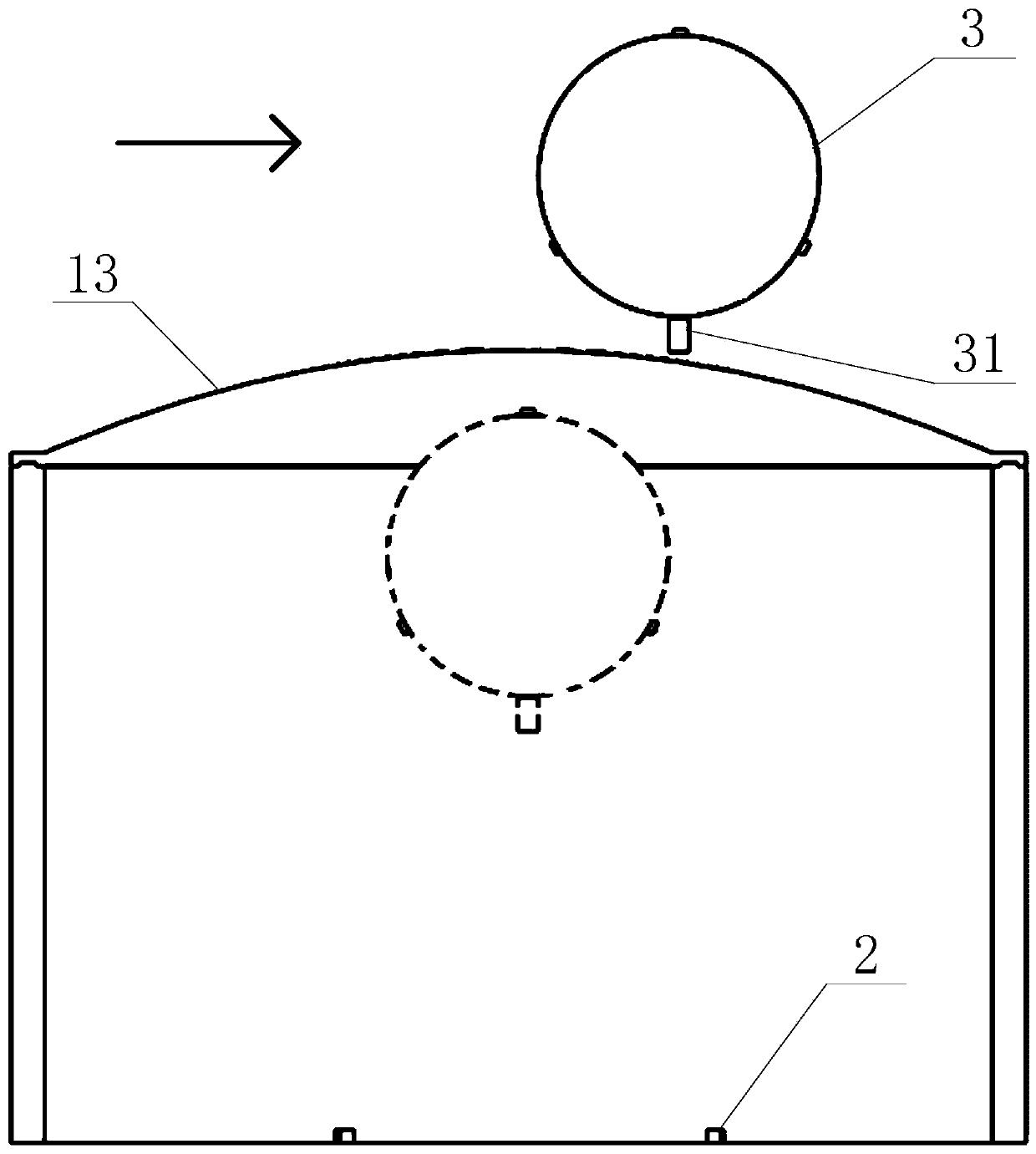

[0055] 1. In the garage where the gate 12 of the garage is closed, lay the airship capsule flat on the ground of the garage, and adjust the mooring device 2 in the garage 1 according to the release size of the airship 3 and the distribution position of its mooring points 32. position, to ensure that a safe distance is left between the projection of the hull and the sideline of the opening and closing area on the top of the garage when the airship is released.

[0056] like figure 1 As shown, the top cover 13 of the boat garage 1 can be divided into two parts and opened and closed respectively to the boat garage door side and the rear side along the top cover slide rail 14. The boat garage door 12 can be opened and closed to both sides, and each part of the top cover 13 consists of multiple It consists of a skeleton that can move along the top cover slide rail 14 and a flexible rainproof material covered and fixed thereon. When the boat garage 1 is not in use, the top cover 13...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap