Sliding support hinge for window

A technology for sliding stay hinges and windows, which is applied in the direction of building fastening devices, wing leaf fastening devices, buildings, etc. It can solve the problems of large door and window opening and closing resistance, low load-bearing capacity, easy accumulation of dust and sundries, etc. Achieve the effects of reducing the risk of wear, loosening and falling off, improving load-bearing performance, and large opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other implementations obtained by a person of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

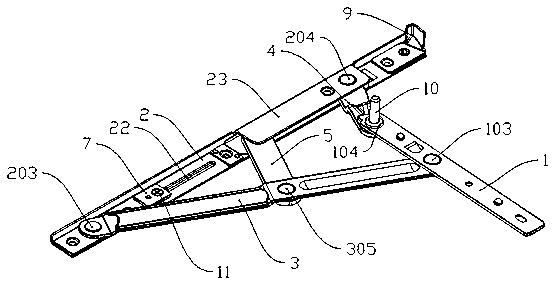

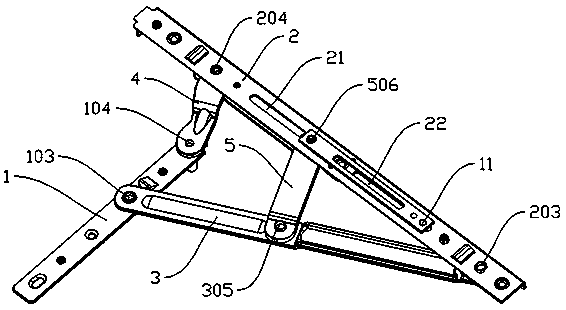

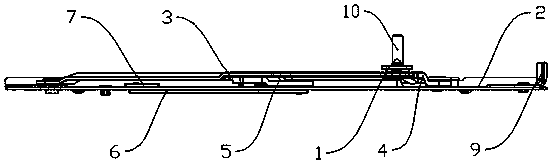

[0021] The purpose of this embodiment is to provide a sliding support hinge for a window, which realizes the opening and closing of the hinge through a rotating structure. Compared with the sliding support in the prior art, the switch is enhanced on the basis of ensuring a large-angle opening. The smoothness, lightness and ease of operation, and improved load-bearing capacity, that is, to avoid the friction between the rivets of sliding hinges for hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com