Method of constructing earthquake-resistant buildings with steel mesh frame polystyrene sandwich panels

A polystyrene and steel wire mesh frame technology, which is used in building construction, building material processing, construction, etc., can solve the problem that the external load requirements of the floor cannot be met, the wall can not be independently load-bearing, and the joints of the wall panels are not well handled. and other problems, to achieve the effects of good seismic resistance, shortened construction period and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

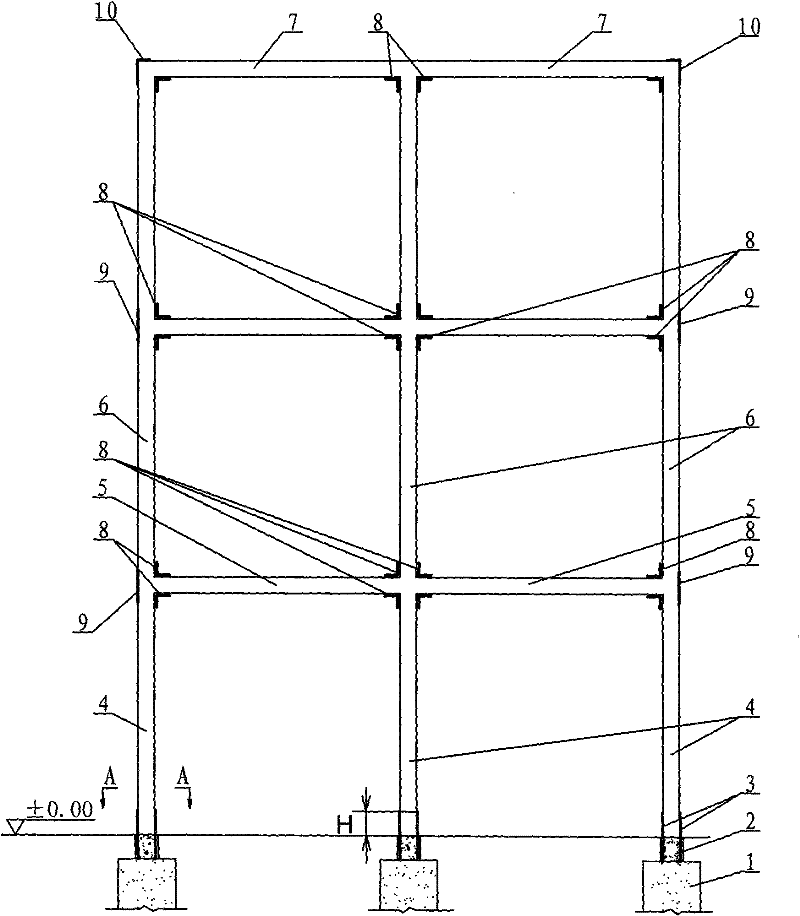

[0007] Specific implementation mode 1: Combination Figure 1~Figure 10 To explain this embodiment, this embodiment is realized by the following steps: Step 1, laying foundation 1; Step 2, laying ground ring beams 2 on foundation 1, and each ground ring beam 2 is provided with two rows of embedded parts 3 , And the two rows of embedded parts 3 are arranged staggered in parallel, the spacing between the embedded parts 3 in each row of embedded parts 3 is 550mm~650mm, and one end of the embedded parts 3 is embedded in the ground ring beam 2. The other end of the embedded part 3 is exposed outside the ground ring beam 2, and the height H of the embedded part 3 exposed outside the ground ring beam 2 is 340mm~360mm. The distance between the two embedded parts 3 and the lower wall 4 Step 3: Install the lower wall 4 between the two embedded parts 3. While installing the lower wall 4, leave the lower window opening and lower door opening; Step 4. Install the lower window opening: lower ...

specific Embodiment approach 2

[0008] Specific embodiment two: specific embodiment three: combination figure 1 To illustrate this embodiment, the lower wall 4 in steps 3 to 6 of this embodiment is a steel wire mesh polystyrene sandwich panel, and the upper wall 6 in steps 7 to 11 is a steel wire mesh polymer The styrene sandwich panel, the steel wire diameter and the web wire diameter in the steel wire mesh frame polystyrene sandwich panel are φ2.5~φ3mm, and the steel wire mesh is 50mm×50mm. This design makes the structure of the steel mesh frame polystyrene sandwich panel reasonable, saves materials and reduces costs. The steel mesh frame polystyrene sandwich panel has the characteristics of independent load-bearing, good seismic performance and environmental protection. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

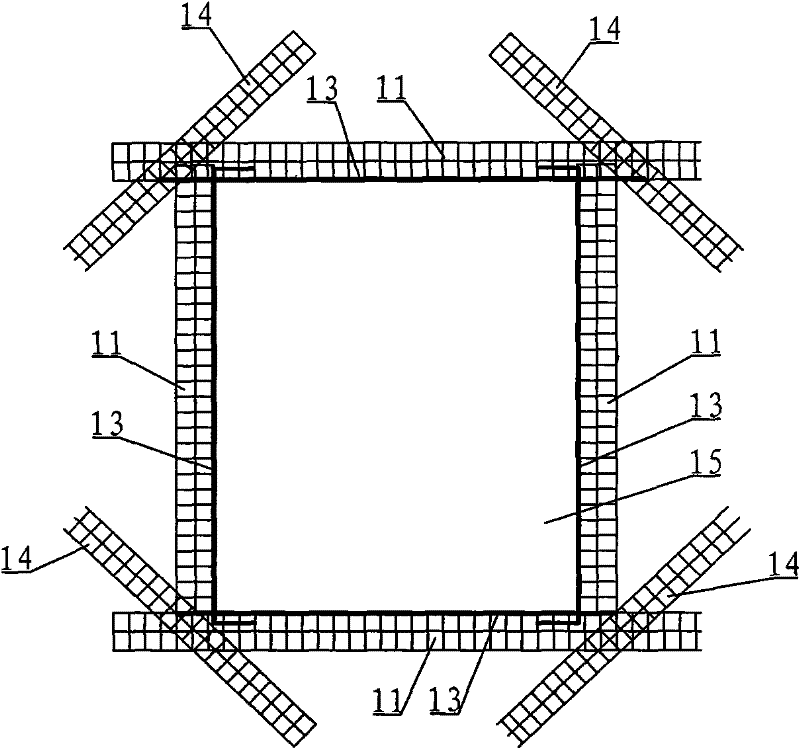

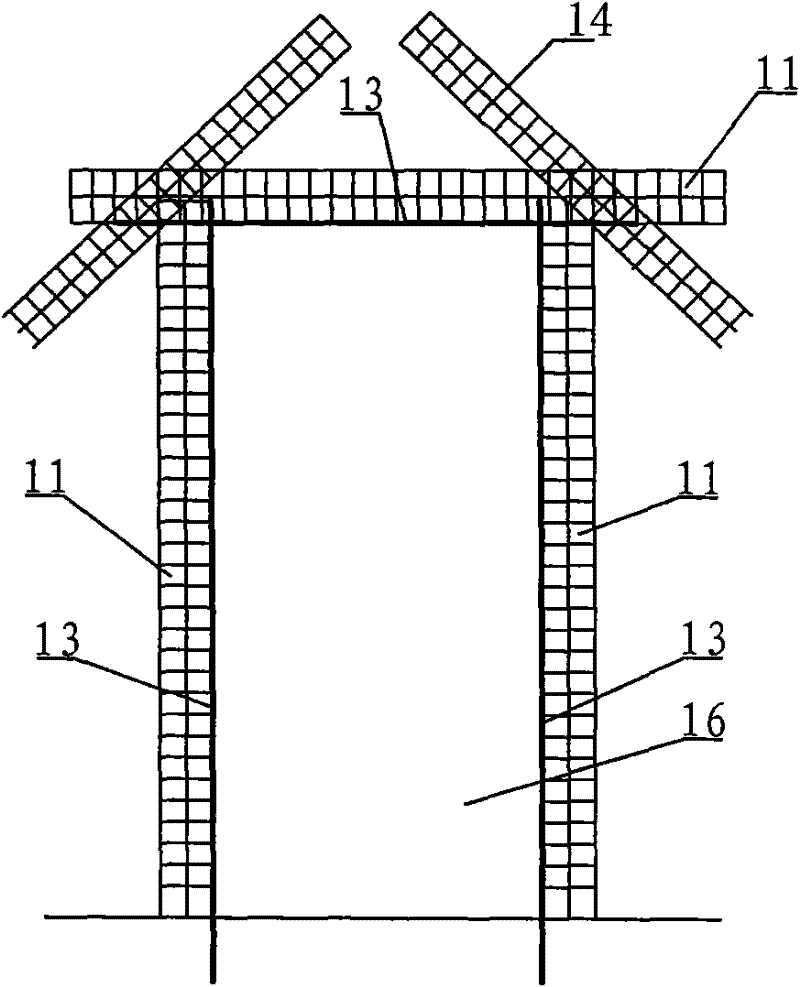

[0009] Specific implementation mode three: combination figure 2 with image 3 To describe this embodiment, the diameter of the steel bar 13 in step 4, step 5, step 8 and step 9 of this embodiment is φ10mm˜φ14mm. The diameter of the steel bar 13 within the above range increases the load-bearing capacity of the window opening and the door opening, improves the wind and snow load of the doors and windows, and greatly improves the overall seismic resistance of the building. The other steps are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com