Mold structure of automobile sealing element

A seal and mold technology, applied in the field of automobile seal mold structure, can solve the problems of difficult online adjustment, difficulty in moulding, and high professional level requirements of mold design engineers, so as to facilitate online debugging, save design and production costs, avoid The effect of multiple designs and modifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

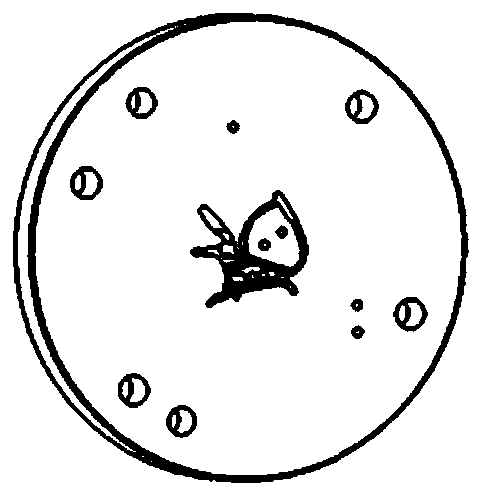

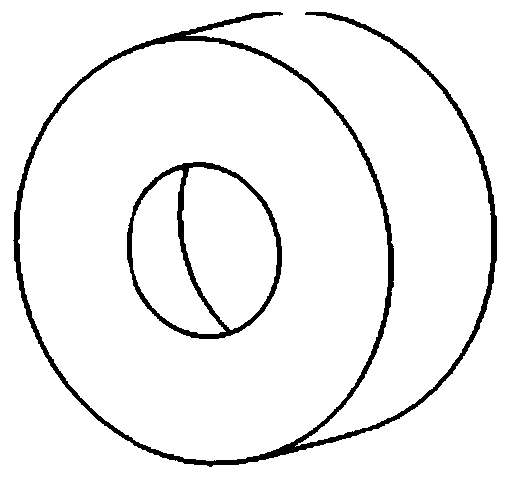

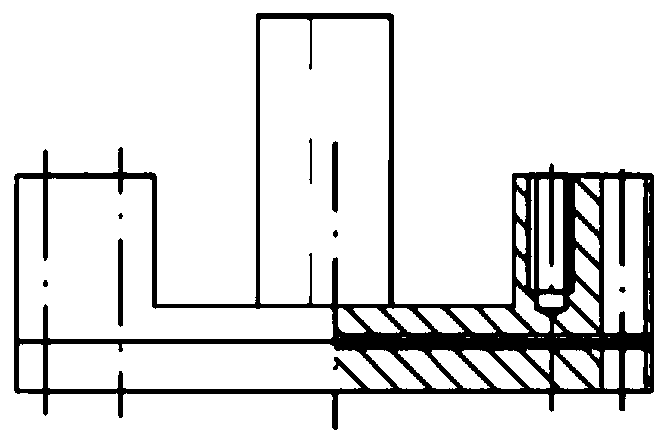

[0017] This example is Figure 4-Figure 8 As shown, it includes the extrusion die manifold, the extrusion die plate and the extrusion die equalizing plate designed with the extrusion die plate: the extrusion die manifold is equipped with a core (usually rubber material) Through the conical hole, there is an outlet hole for the corresponding product in the middle of the extrusion die plate, and the corresponding position of the extrusion die pressure plate is provided with a protrusion that matches the exit hole. In the working state, the extrusion die pressure plate and extrusion The molded die plate is assembled and matched, the protrusion is located in the die hole, and the gap between the protrusion and the die hole forms a cavity, and the protrusions and the periphery of the protrusion of the extrusion die equalizing plate are reserved for multiple glue outlets that can be adjusted in real time according to the actual die structure. Port 1, in the initial state, process th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com