Pneumatic control self-induction pneumatic balance crane

A pneumatic balance hoist and self-induction technology, applied in the direction of lifting device, etc., can solve the problems of incapable of lifting and moving objects of different weights, limiting the use range of pneumatic balance hoists, and limiting the hoisting range of pneumatic balancers, etc., so as to reduce the working cycle time. , Improve operation safety and expand the effect of hoisting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

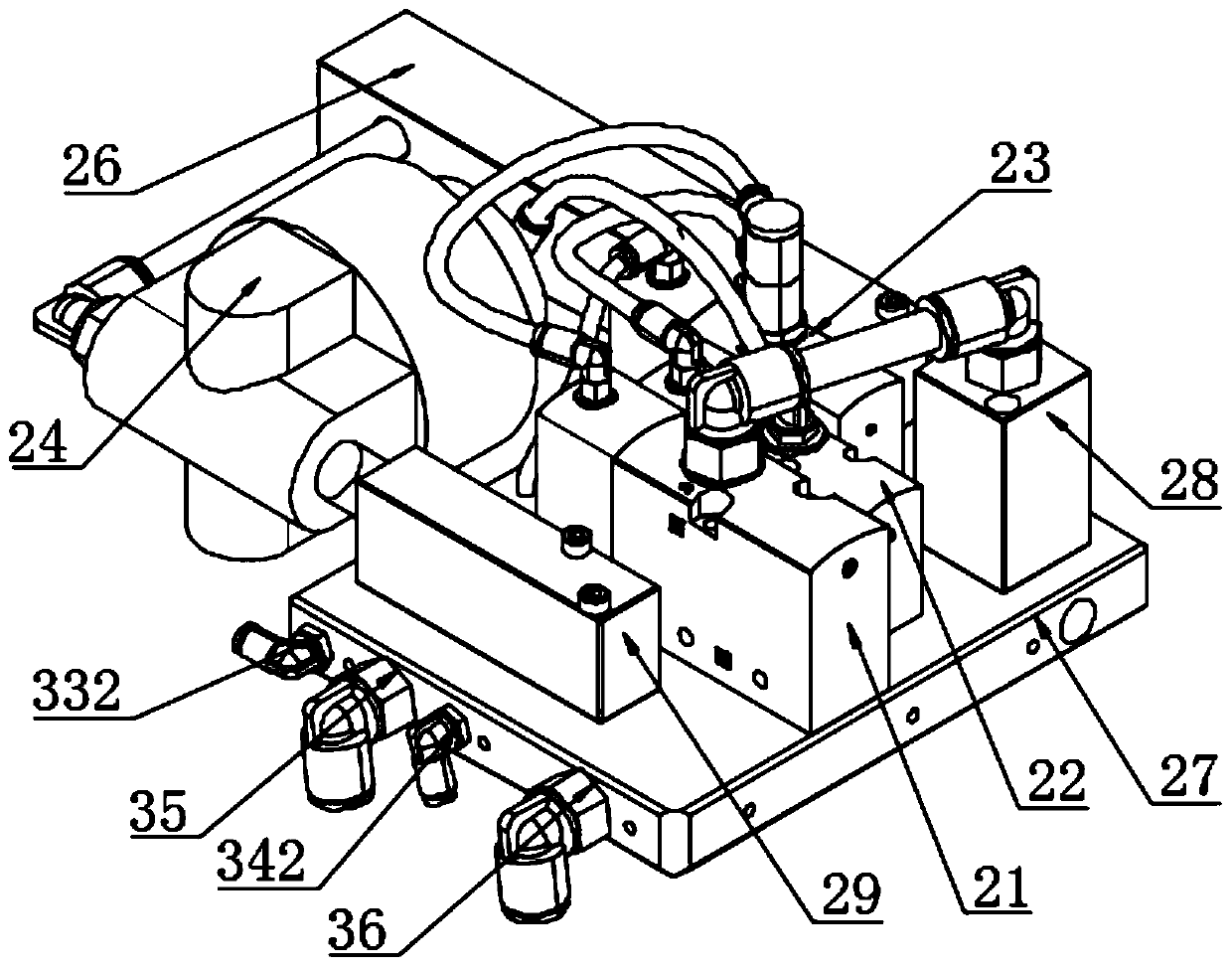

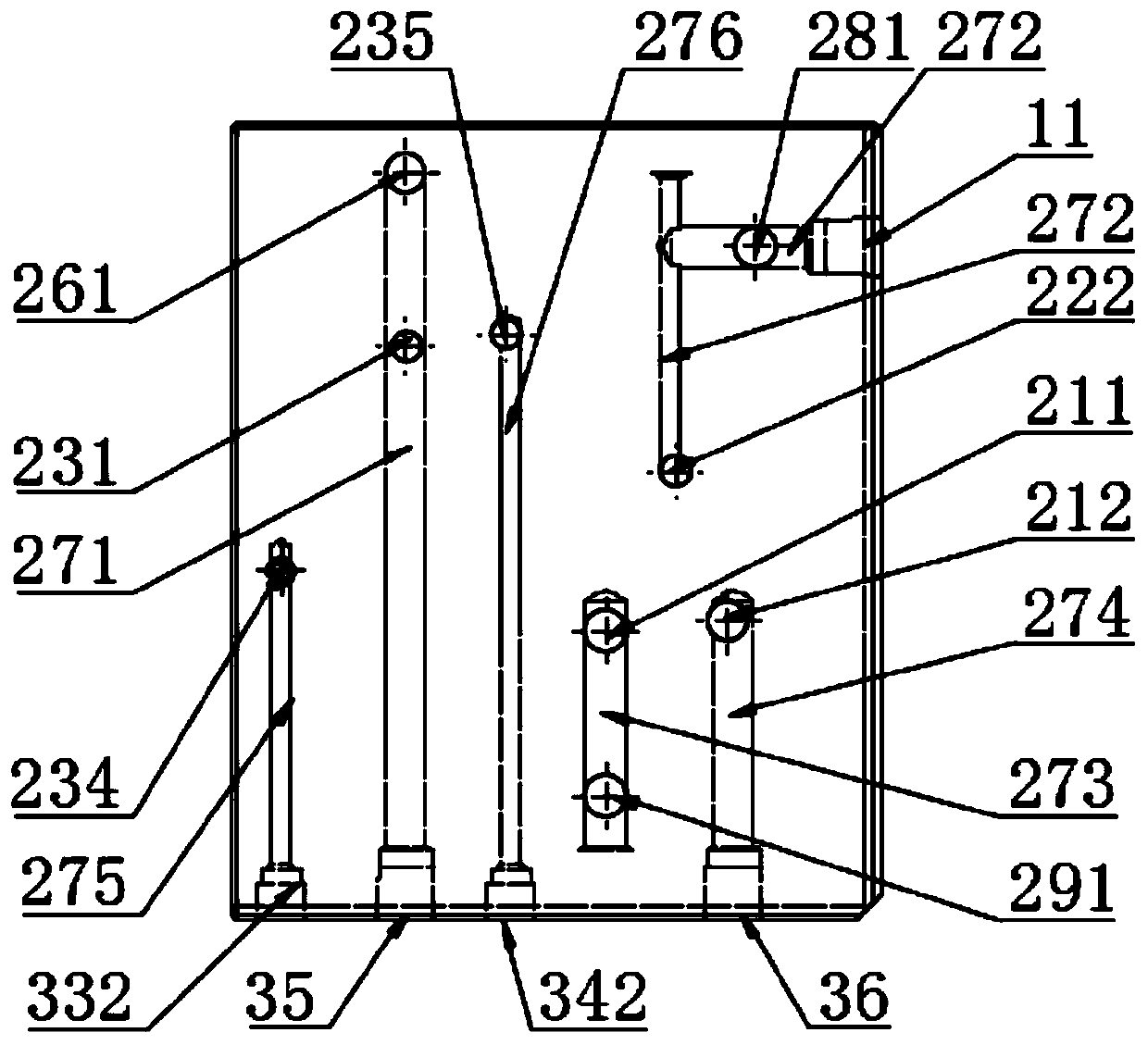

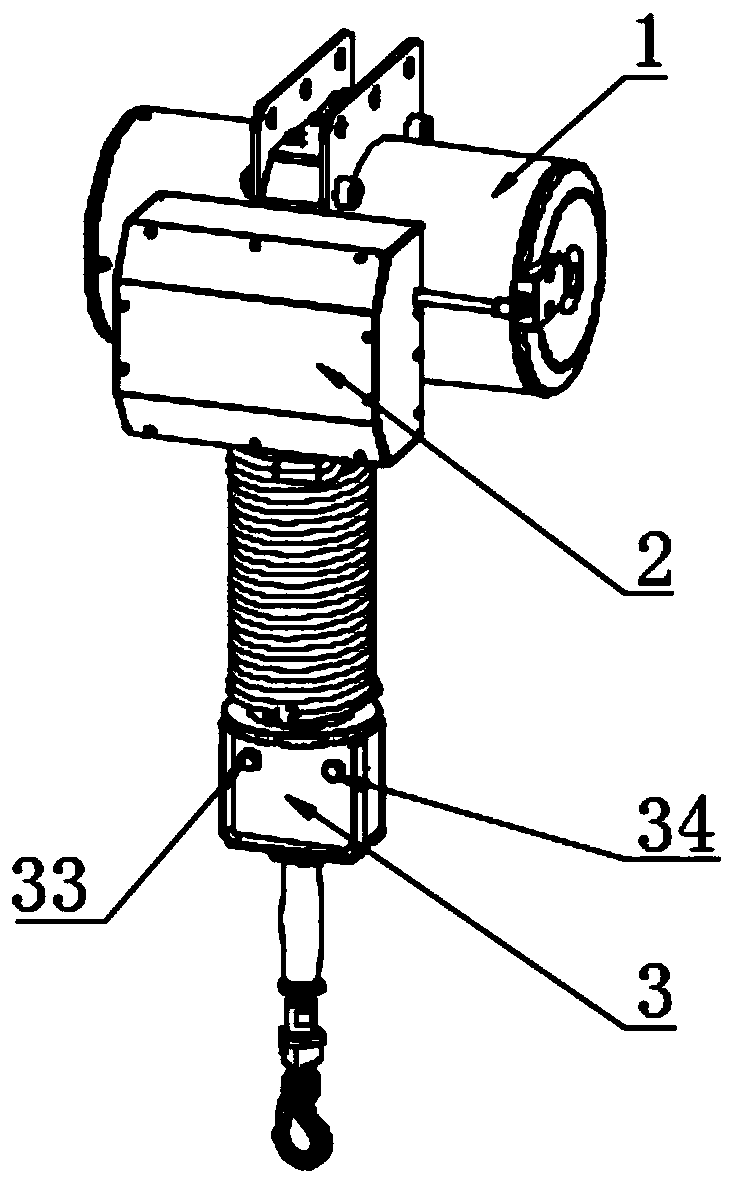

[0022] Such as Figure 1-Figure 4 As shown, an air-controlled self-induction pneumatic balance crane includes an air suspension main body 1 and an operating device 3 connected through an air control box 2, and the operating device 3 is provided with a lifting switch 31, a lowering switch 32, a button A 33 and a button B 34. The air control box 2 is provided with a fixedly connected air circuit board 27, and the air circuit board 27 is provided with fixedly connected valve C 21, valve B 22, valve A 23, air intake connector 26, connector A 28 and Connecting piece B 29, an air-controlled decompression valve 24 is provided between the intake connecting piece 26 and connecting piece B 29, connecting piece B 29 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com