Large-span bridge girder hoisting system based on Beidou positioning

A Beidou positioning and large-span technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor accuracy, affecting the driver's monitoring of the cable hoisting system, and large synchronization errors, so as to achieve accurate hoisting height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

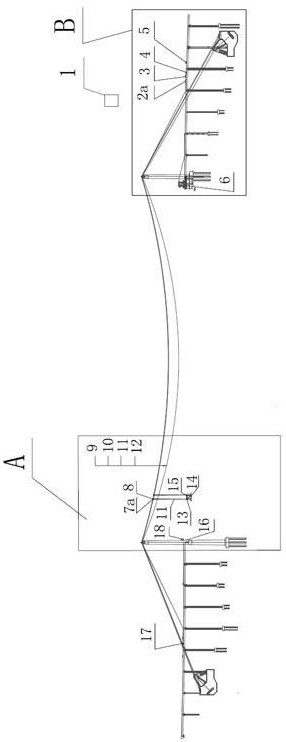

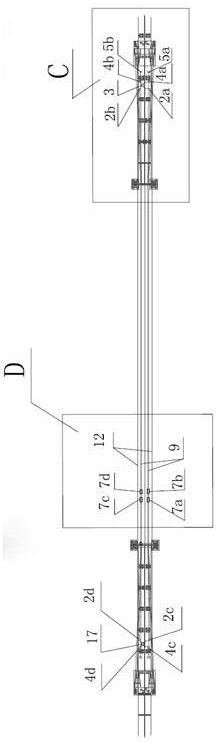

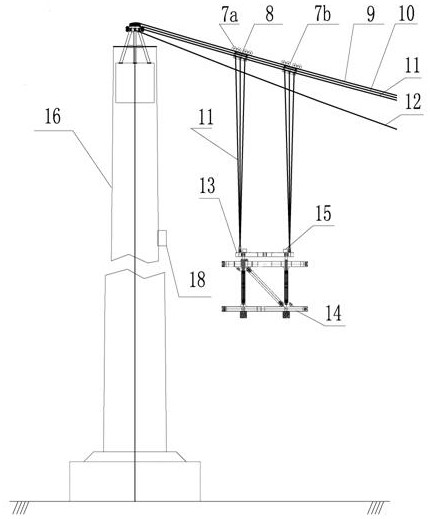

[0026] like figure 1 , 2 , 4 and 5, the Beidou positioning-based long-span bridge main girder hoisting system of the present invention includes a three-dimensional precise positioning system and an automatic hoisting control system; the three-dimensional precise positioning system includes the Beidou reference station 1 and the first Beidou positioning terminal. 8. The second Beidou positioning terminal 15, differential service system and data center; the Beidou reference station 1 continuously tracks and observes Beidou satellite signals, transmits satellite information in real time through the network, and provides high-precision carrier phase difference for the Beidou positioning terminal in real time. Data; the first Beidou positioning terminal 8 is installed on the sports car, and four sports cars are used in this system, namely the No. 1 sports car 7a, the No. 2 sports car 7b, the No. 3 sports car 7c, and the No. 4 sports car 7d, each sports car is equipped with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com