Aluminum alloy door and window waste recycling device

A technology for recycling aluminum alloy doors and windows and waste materials, applied in the field of aluminum alloy doors and windows, can solve the problems of small recycling loading, small recycling capacity, and difficulty in compaction, so as to reduce loading costs, increase recycling loading, and increase recycling capacity. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

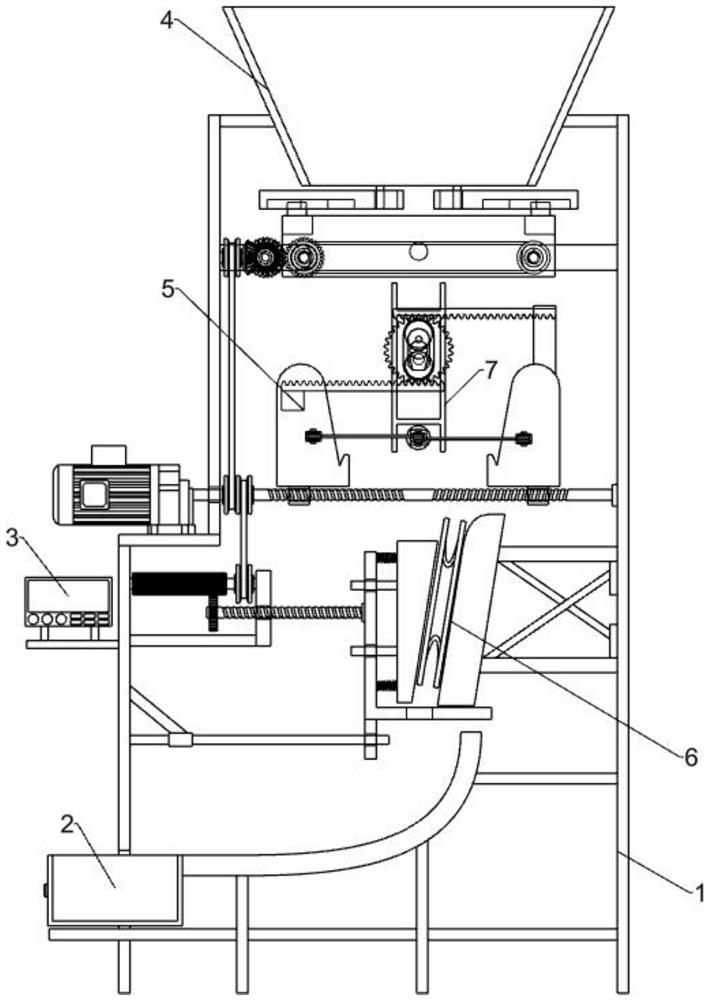

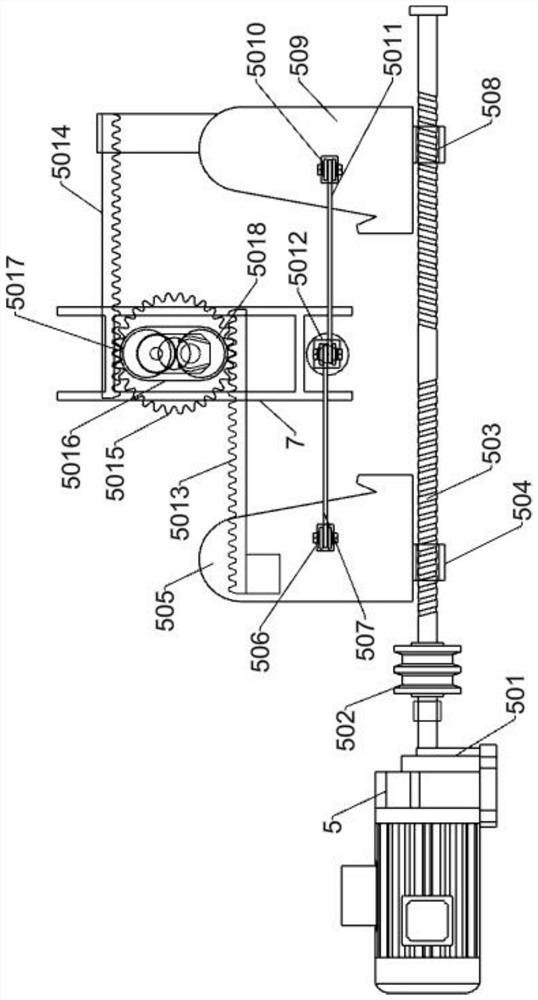

[0029] A kind of aluminum alloy doors and windows waste recycling device, such as Figure 1-6 As shown, it includes an outer frame 1, a collection box 2, a control panel 3, a positioning and unloading mechanism 4, a shuttle pressure mechanism 5, a constant pressure mechanism 6 and aluminum alloy waste 7; a collection box 2 is placed on the left side of the inner bottom of the outer frame 1; A control panel 3 is arranged under the left middle part of the outer frame 1; a positioning and blanking mechanism 4 is arranged on the inner top of the outer frame 1; The inner bottom of the outer frame 1 is provided with a constant pressure mechanism 6, and the left side of the top of the constant pressure mechanism 6 is connected with the shuttle press mechanism 5; the middle part of the shuttle press mechanism 5 is provided with aluminum alloy waste 7.

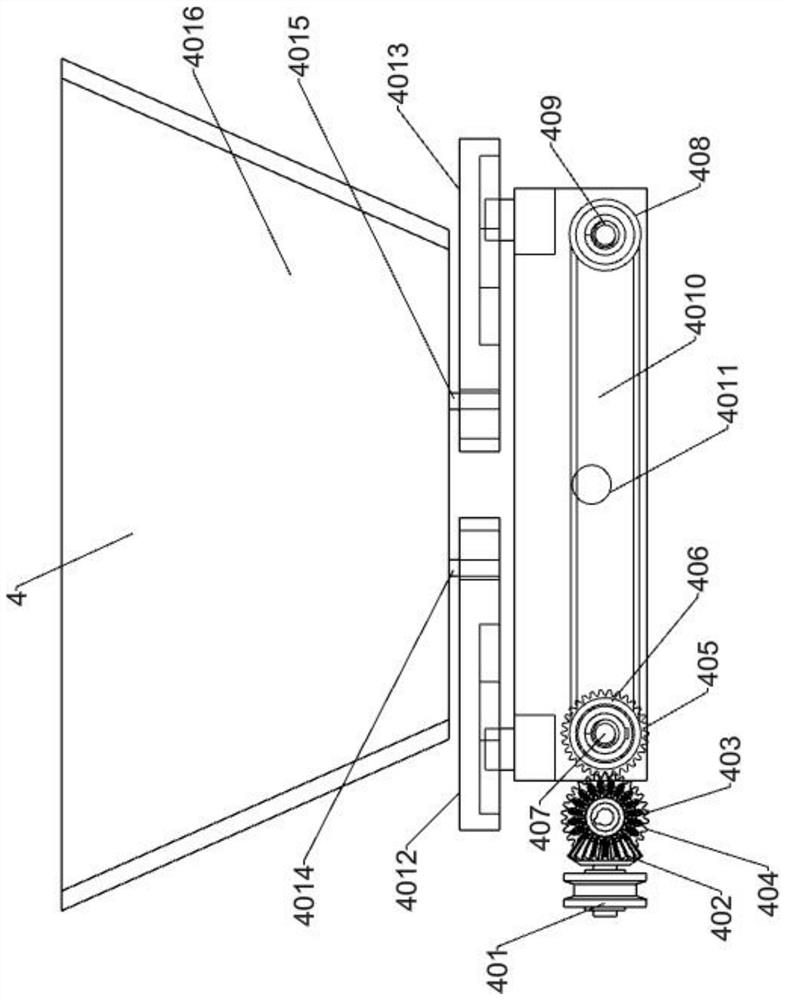

[0030] Wherein, the positioning blanking mechanism 4 comprises a first monorail transmission wheel 401, a first bevel gear 402, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com