A wear-resistant, high-strength carbon structural steel material

A carbon structural steel, high-strength technology, applied in the field of high-strength carbon structural steel materials, wear resistance, can solve the problems of reduced toughness and wear resistance, and achieve improved toughness and wear resistance, good strength and wear resistance Abrasiveness and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

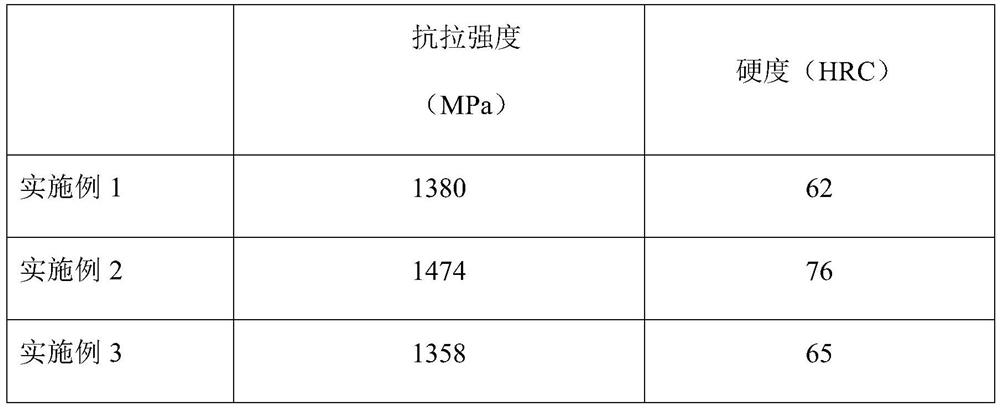

Embodiment 1

[0024] A wear-resistant, high-strength carbon structural steel material, the specific chemical composition of the steel is C: 0.12%, Si: 0.16%, Cr: 1.2%, Ni: 0.15%, Al 0.03%, N: 0.05 %, V: 0.5%, Mo: 0.35%, Mn: 0.7%, Zr: 1.0%, Ta: 0.05%, S: 0.005%, B: 0.005%, Ba: 0.003%, P≤0.0015%, the balance is Fe and unavoidable impurities;

[0025] (1) The components are weighed according to the weight of each chemical composition, and the mixed materials are smelted and cast into billets; hot-rolled through a hot-pressing furnace, which adopts a high-efficiency walking beam heating furnace and is controlled by an industrial computer and PLC. The system can realize automatic combustion according to the set parameters, the preheating section is ≤850°C, the starting rolling temperature is 1050°C, the final rolling temperature is 860°C, and the billet heating time is 3h; the reduction rate of hot rolling is ≥90%; after hot rolling Turn on the high-pressure water for phosphorus removal, and th...

Embodiment 2

[0030] A wear-resistant, high-strength carbon structural steel material, the specific chemical composition of the steel is C: 0.1%, Si: 0.16%, Cr: 1.0%, Ni: 0.25%, Al: 0.04%, N: 0.03%, V: 0.7%, Mo: 0.3%, Mn: 0.6%, Zr: 1.2%, Ta: 0.02%, S: 0.001%, B: 0.004%, Ba: 0.002%, P≤0.0015%, balance It is Fe and unavoidable impurities; where (Mo+V)≥0.8%, (Mn+V)≤1.3%

[0031] (1) The components are weighed according to the weight of each chemical composition, and the mixed materials are smelted and cast into billets; hot-rolled through a hot-pressing furnace, which adopts a high-efficiency walking beam heating furnace and is controlled by an industrial computer and PLC. The system can realize automatic combustion according to the set parameters, the preheating section is ≤850°C, the starting rolling temperature is 1050°C, the final rolling temperature is 880°C, and the billet heating time is 4h; the reduction ratio of hot rolling is ≥95%; after hot rolling Turn on high-pressure water for p...

Embodiment 3

[0036] A wear-resistant, high-strength carbon structural steel material, the specific chemical composition of the steel is C: 0.08%, Si: 0.17%, Cr: 1.0%, Ni: 0.34%, Al: 0.05%, N: 0.04%, V: 0.9%, Mo: 0.25%, Mn: 0.4%, Zr: 1.2%, Ta: 0.01%, S: 0.003%, B: 0.004%, Ba: 0.004%, P≤0.0015%, balance is Fe and unavoidable impurities;

[0037] (1) The components are weighed according to the weight of each chemical composition, and the mixed materials are smelted and cast into billets; hot-rolled through a hot-pressing furnace, which adopts a high-efficiency walking beam heating furnace and is controlled by an industrial computer and PLC. The system can realize automatic combustion according to the set parameters, the preheating section is ≤850°C, the starting rolling temperature is 1080°C, the final rolling temperature is 880°C, and the billet heating time is 5h; the reduction ratio of hot rolling is ≥95%; after hot rolling Turn on high-pressure water for phosphorus removal, and the phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com