High-wear resistance steel plate and manufacturing method thereof

A technology of high wear resistance and manufacturing method, which is applied in the field of high wear resistance steel plate and high wear resistance steel plate manufacturing, which can solve the problems of poor processing performance of steel materials and increased cracking tendency of wear-resistant parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

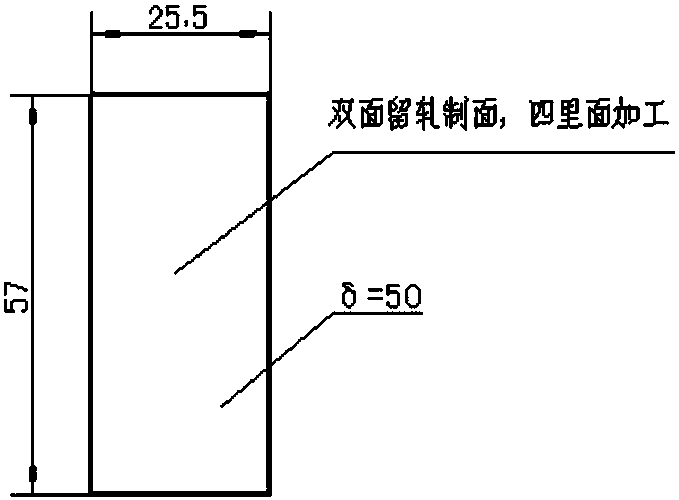

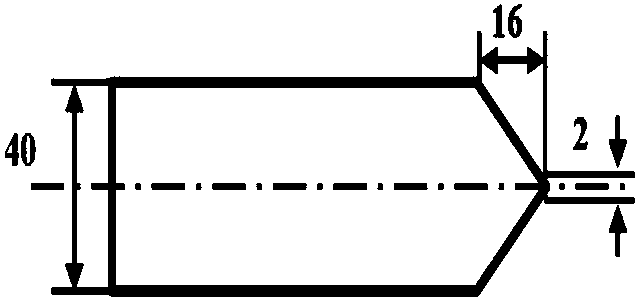

Image

Examples

Embodiment 1

[0025] According to the high wear resistance steel plate of the embodiment of the present invention, its chemical composition includes: C: 0.15-0.17%, Si: 0.15-0.30%, Mn: 1.10-1.40%, P: ≤0.012%, in weight percentage, S: ≤0.002%, Cr: 0.40~0.90%, Ti: 0.008~0.018%, B: 0.0010~0.0020%, Mo: 0.15~0.40%, Ni: 0.10~0.30%, Ce: ≤0.0030%, Als: 0.025 ~0.04%, CEV: 0.48~0.64%.

[0026] Preferably, in terms of weight percentage, its chemical composition includes: C: 0.15-0.17%, Si: 0.20-0.30%, Mn: 1.20-1.30%, P: 0.008-0.012%, S: ≤0.002%, Cr: 0.40 ~0.80%, Ti: 0.012~0.014%, B: 0.0015~0.0020%, Mo: 0.18~0.40%, Ni: 0.14~0.16%, Ce: ≤0.0015%, Als: 0.030~0.033%, CEV: 0.48~0.64 %.

[0027] The alloy composition of the high wear resistance steel plate in this embodiment is mainly low carbon and low alloy, making full use of rare earth to improve the dendrite segregation, microstructure, grain size, weldability, formability, and high wear resistance of the slab. The addition of rare earth is beneficia...

Embodiment 2

[0030] According to the manufacturing method of the high wear resistance steel plate of the embodiment of the present invention, its chemical composition is shown in Table 1 in terms of weight percentage, wherein Comparative Example 1 is a steel plate with a hardness of 400HB, including:

[0031] (1) Smelting

[0032] The molten iron for smelting is pretreated by desulfurization, adding scrap steel, heating by LF refining, adding Cr and Mo to adjust to the target composition, alloying, refining off-site temperature 1600 ℃, RH vacuum treatment, vacuum treatment time 20min, adding rare earth content during vacuum treatment It is a 10% Ce-Fe alloy. By adding this alloy, the yield of rare earth can reach more than 50%. Before adding the Ce-Fe alloy, measure the temperature and determine the oxygen. The content of active oxygen is required to be less than 5ppm, and the temperature is 1580°C. It is to improve the yield of rare earth and control the inclusions in steel. After the va...

Embodiment 3

[0040]According to the manufacturing method of the high wear resistance steel plate of the embodiment of the present invention, its chemical composition is shown in Table 1 by weight percentage, including:

[0041] (1) Smelting

[0042] The molten iron for smelting is pretreated by desulfurization, adding scrap steel, heating by LF refining, adding Cr and Mo to adjust to the target composition, alloying, refining off-site temperature 1600 ℃, RH vacuum treatment, vacuum treatment time 20min, adding rare earth content during vacuum treatment It is a 10% Ce-Fe alloy. By adding this alloy, the yield of rare earth can reach more than 50%. Before adding the Ce-Fe alloy, measure the temperature and determine the oxygen. The content of active oxygen is required to be less than 5ppm, and the temperature is 1580°C. It is to improve the yield of rare earth and control the inclusions in steel. After the vacuum treatment, perform soft blowing. During the soft blowing period, the slag surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com