A multi-pulse solid rocket motor

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as small thrust, achieve large thrust, increase initial combustion area, and achieve the effect of repeated starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

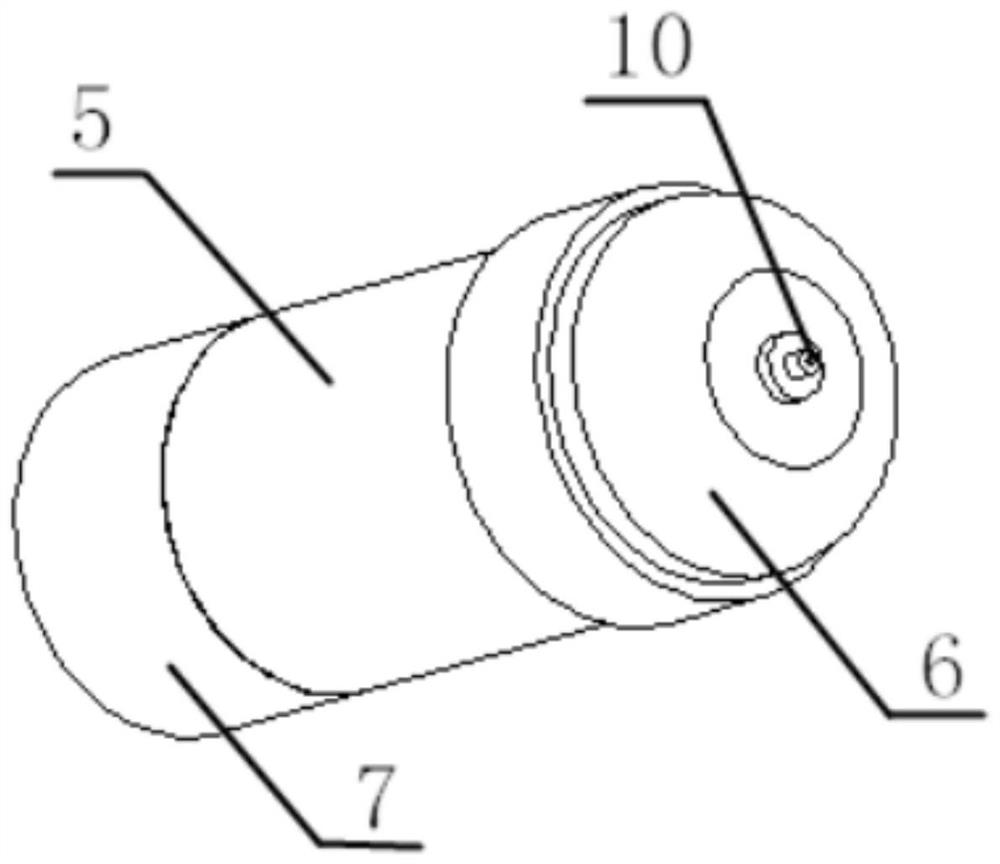

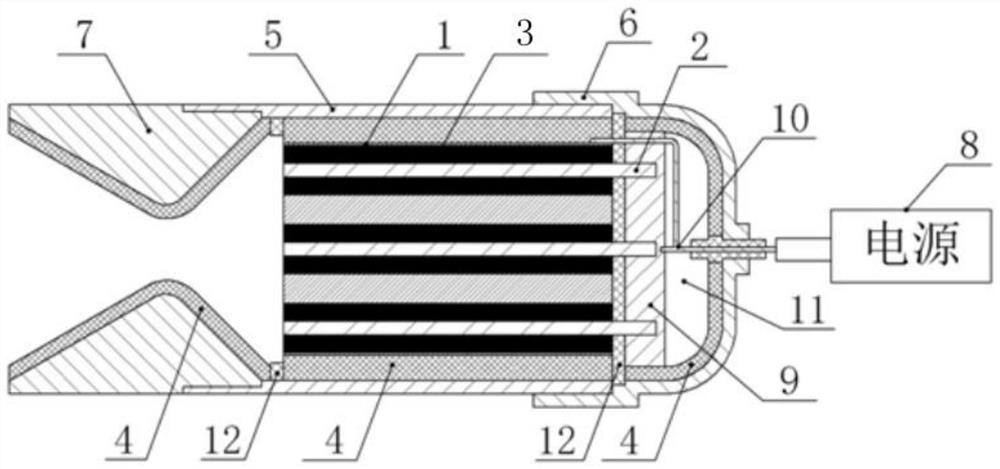

[0042] Such as Figure 1-Figure 2 A multi-pulse solid rocket motor shown includes an outer electrode 1, an inner electrode 2, a solid propellant 3, an insulating layer 4, a motor case 5, a front head 6, a nozzle 7, a power supply 8, and a fixed inner electrode Seat 9, lead wire 10 and drug retaining plate 12, the inside of described engine housing 5 is hollow structure, and both ends are respectively detachably connected to front head 6 and nozzle 7 by threads or flanges; The ignition device can realize greater thrust while controlling the thrust of the engine in real time, and has broad application prospects in the field of multi-pulse rocket engines that need to generate high thrust.

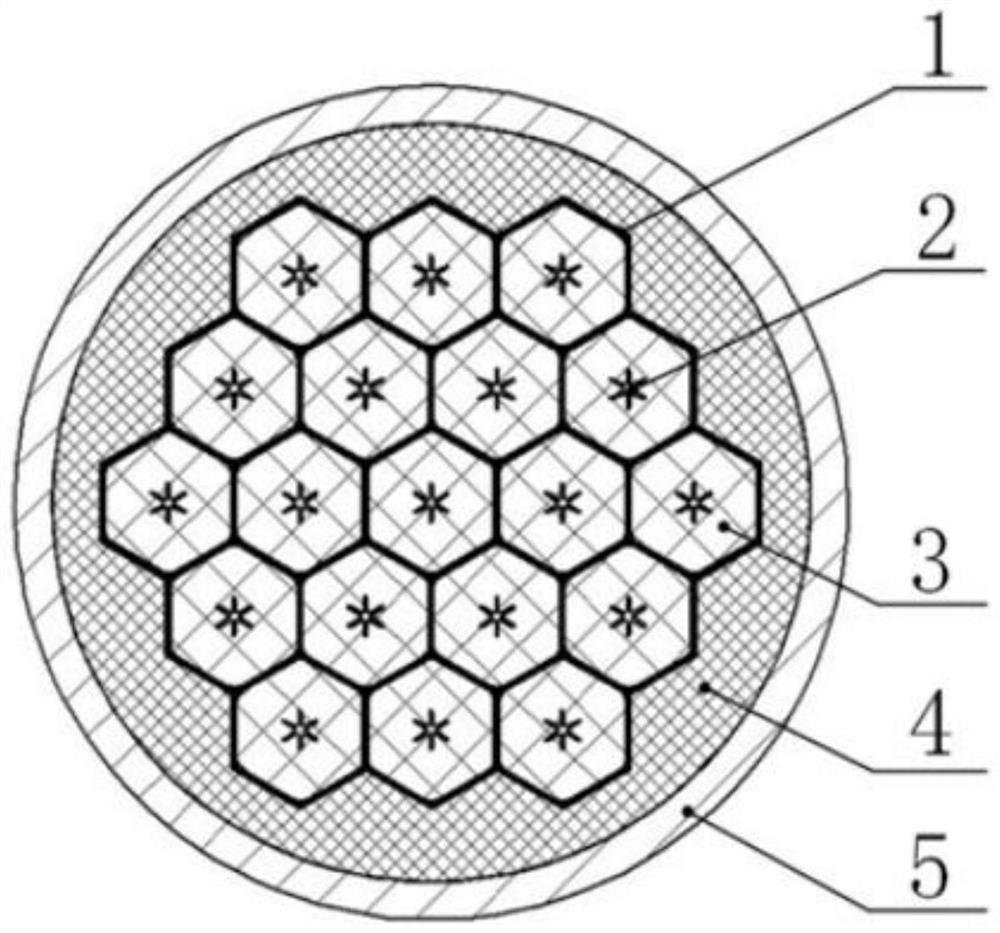

[0043] Such as Figure 3-Figure 4 As shown, the external electrode 1 has 19 densely arranged honeycomb-shaped through holes 13, each of which is closely adjacent to each other, and the inner cavity of each of the honeycomb-shaped through-holes 13 serves as a combustion chamber. In this embodi...

Embodiment 2

[0063] as attached Figure 1-Figure 2 Another multi-pulse solid rocket motor shown includes an outer electrode 1, an inner electrode 2, a solid propellant 3, an insulating layer 4, a motor casing 5, a front head 6, a nozzle 7, a power supply 8, and an inner electrode The fixing seat 9, the wire 10 and the medicine retaining plate 12; the difference from the first embodiment is that: in this embodiment, the external electrode 1 has m densely arranged honeycomb through holes (m is greater than 19 and 7 is Integer with increasing arithmetic difference), after increasing the honeycomb through-holes, the thrust of this embodiment can be further improved to meet the greater thrust requirement.

Embodiment 3

[0065] as attached Figure 1-Figure 2 Another multi-pulse solid rocket motor shown includes an outer electrode 1, an inner electrode 2, a solid propellant 3, an insulating layer 4, a motor casing 5, a front head 6, a nozzle 7, a power supply 8, and an inner electrode The fixing seat 9, the wire 10 and the medicine retaining plate 12; the difference from the first embodiment is that in this embodiment, each of the honeycomb-shaped through holes 13 has a regular n-gonal cross-section (n is an integer greater than 6), when When the honeycomb-shaped through holes 13 have more surfaces, the contact area between the internal electrode 2 and the solid propellant 3 can be increased, which further helps to increase the initial combustion area of the solid propellant 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com