Outwards-leaked gate valve middle cavity overpressure protection device

An overpressure protection device and technology for overpressure protection, applied to valve devices, devices for pressure relief on the sealing surface, valve details, etc., can solve the problem of the sealing surface losing its sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

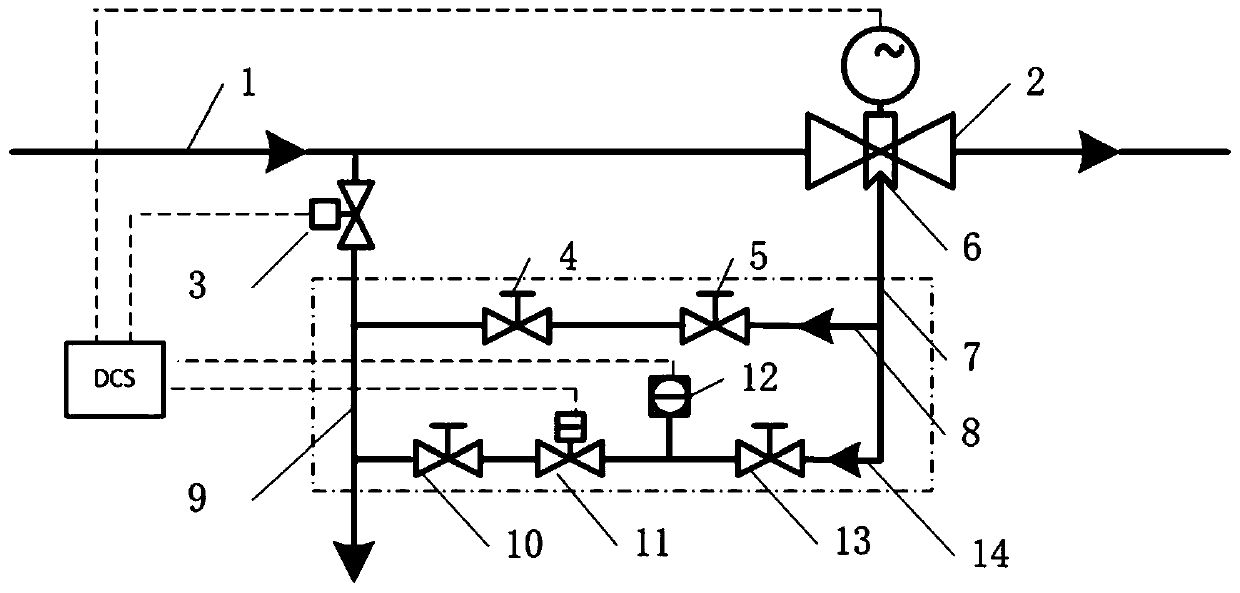

[0024] An overpressure protection device for the inner cavity of a gate valve with external discharge, combined with figure 1 As shown, it includes the main pipeline 1 at the inlet side, the drain pipeline 9 before the valve, the steam trap 3, the overpressure protection system and the DCS controller.

[0025] The main pipeline 1 on the inlet side communicates with the inlet side of the double gate valve 2, and is used for conveying high-temperature and high-pressure fluid.

[0026] The drain pipe 9 before the valve is connected to the bottom of the main pipe 1 on the inlet side, and is used to fully drain water when the system is started, so as to prevent the accumulation of water in the main pipe 1 on the inlet side.

[0027] The drain valve 3 is arranged on the drain pipe 9 in front of the valve, and is used to control the opening and closing of the drain pipe 9 in front of the valve.

[0028] The overpressure protection system is connected between the drain pipe 9 located...

Embodiment 2

[0040] Based on the basis of Embodiment 1, the difference between this embodiment and Embodiment 1 is that a manual external pressure relief overpressure protection system is also connected between the main pipe 7 of the external discharge pipeline and the drain pipe 9 before the valve. The pressure and overpressure protection system is used for manual operation when the automatic external pressure relief and overpressure protection system fails, so as to discharge the fluid in the cavity of the double gate valve into the drain pipe 9 in front of the valve. The manual external pressure relief and overpressure protection system is the manual pressure relief redundant system, which is set in parallel with the automatic external pressure relief and overpressure protection system.

[0041] The manual external pressure relief overpressure protection system includes a manual external discharge pipeline 8 connected between the main pipe 7 of the external discharge pipeline and the dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com