Filtering equipment for intelligent production

A technology of filtration equipment and intelligent production, applied in the fields of filtration treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problem of not having multi-dimensional filtration means and not having good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

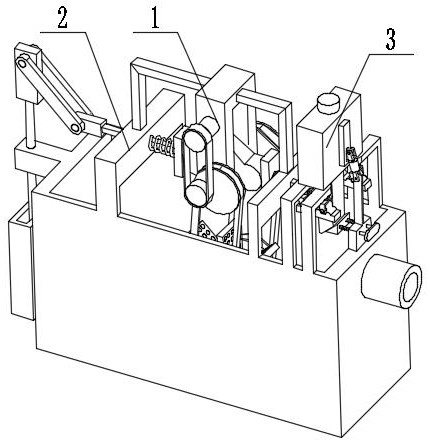

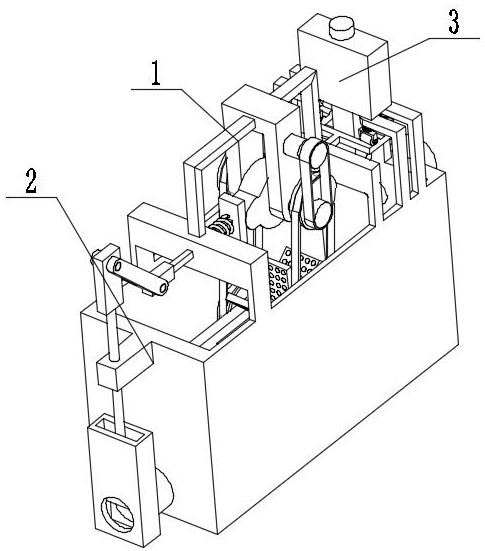

[0029] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe this embodiment, the present invention relates to a filter device, more specifically a filter device for intelligent production, including a filter mechanism 1, a box body mechanism 2, a flocculant adding mechanism 3, the equipment can filter, and the equipment can The addition of flocculant is realized in the filtration, the equipment can control whether to add flocculant, and the equipment can discharge water intermittently to ensure the effective filtration.

[0030] The filter mechanism 1 is connected with the box mechanism 2, the box mechanism 2 is connected with the flocculant adding mechanism 3, and the filter mechanism 1 is in contact with the flocculant adding mechanism 3.

specific Embodiment approach 2

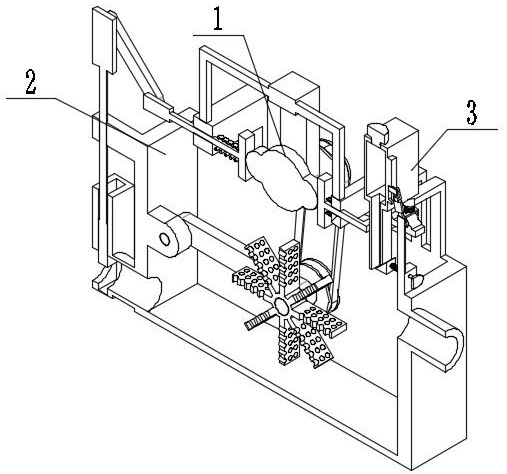

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13Describe this embodiment, this embodiment will further explain the first embodiment, the filter mechanism 1 includes a swing arm 1-1, a hinged rod 1-2, a pulley 1-3, a V-belt 1-4, and a filter wheel 1-5 , Shaft pulley I1-6, eccentric pulley 1-7, transmission belt 1-8, motor pulley 1-9, filter motor 1-10, bearing seat 1-11, connecting shaft 1-12, rotating shaft I1-13, double Cam pulley 1-14, swing arm 1-1 is connected with hinge rod 1-2, belt pulley 1-3 is connected with connecting shaft 1-12, belt pulley 1-3 is frictionally connected with V-belt 1-4, filter wheel 1-5 It is connected with the connecting shaft 1-12, the connecting mode of the connecting shaft 1-12 and the swing arm 1-1 is a bearing connection, the belt pulley I1-6 is connected with the rotating shaft I1-13, and the rotating sha...

specific Embodiment approach 3

[0034] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe this embodiment, this embodiment will further explain the first embodiment, the box mechanism 2 includes a box body 2-1, a water outlet pipe 2-2, a door seat 2-3, a water outlet 2-4, a sliding door 2-5, door chute 2-6, connecting rod 2-7, protruding seat 2-8, light hole 2-9, hinged seat 2-10, hinged arm 2-11, hinged connecting seat A2-12, square slide Rod 2-13, square hole 2-14, spring 2-15, mating seat 2-16, square hole I2-17, bent arm support with holes 2-18, hinged support I2-19, triangular section seat 2-20, Support slide bar 2-21, return spring 2-22, opening 2-23, connecting plate 2-24, water inlet pipe 2-25, hinge seat A2-26, box body 2-1 is connected with bearing seat 1-11 , the box body 2-1 is connected with the water outlet pipe 2-2, the water outlet pipe 2-2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com