Test system and test method for performance evaluation in active equipment in accident environment

A test system and equipment technology, which is applied in the field of test systems for performance evaluation of active equipment in an accident environment, can solve problems such as the inability to identify or evaluate the action capability of active equipment, and achieve the effects of preventing core melting, high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

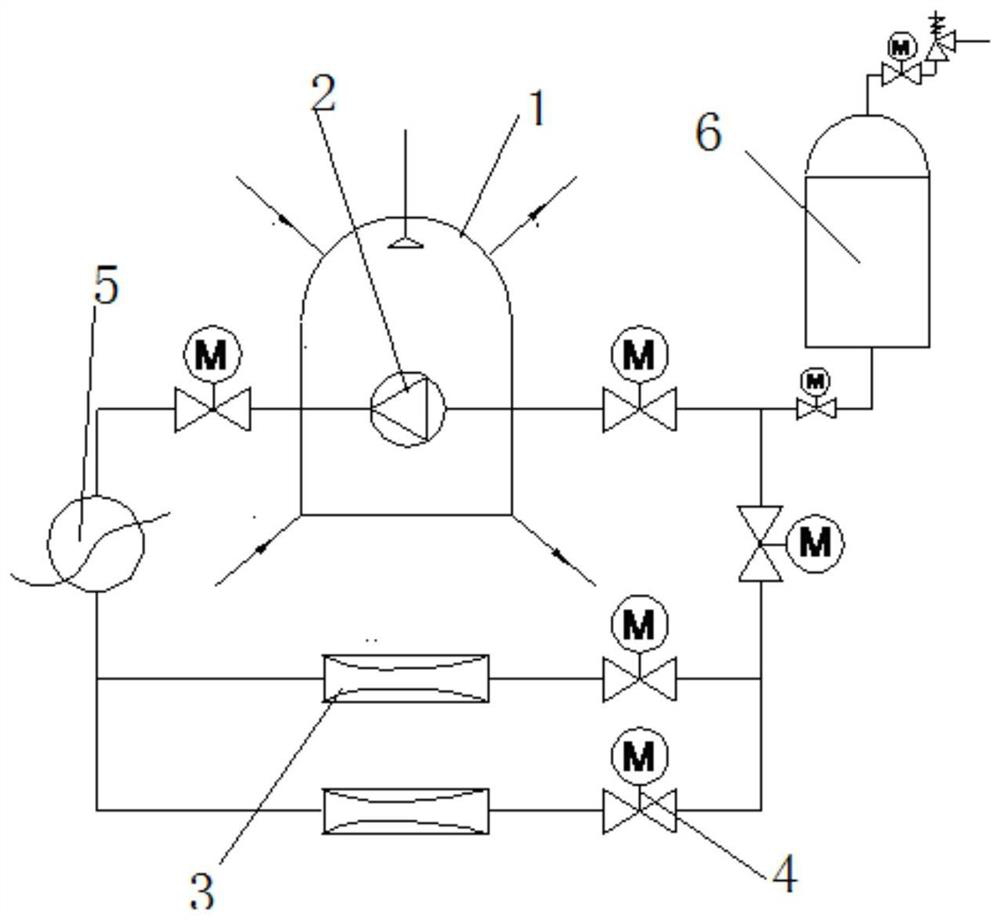

[0031] Such as figure 1 As shown, the test system for performance evaluation of active equipment accident environment includes active equipment 2 set in the environmental chamber 1, the environmental chamber 1 is used to simulate the environmental working conditions in the environment of loss of water accident, and also includes the main circuit, switching circuit, the main circuit, switching circuit, and active device 2 are connected in series, the main circuit is used to simulate the pressure difference and temperature difference of the circuit, and the switching circuit is used to detect the action switching capability of the active device 2 . When the system is working, first simulate the environmental working conditions of the dehydration accident through the environmental chamber 1, adjust the temperature and pressure in the environmental chamber 1 by controlling the steam inlet and outlet of the environmental chamber 1, and place the active equipment 2 in the environment...

Embodiment 2

[0033] Such as figure 1 The test system for performance evaluation under the accident environment of energy level equipment, on the basis of embodiment 1,

[0034]The switching circuit includes N bypass circuits, and any two bypass circuits are connected in parallel; wherein N≥2; further, the bypass circuit includes a flow meter 3 and a bypass throttle valve 4, and the flow meter 3 And bypass throttle valve 4 in series. The number of bypass loops in this embodiment is two, and the two bypass loops are connected in parallel.

[0035] The main circuit includes a heater 5 and a voltage stabilizer 6 , and the active device 2 is located between the heater 5 and the voltage stabilizer 6 . Control throttling valves are provided between the heater 5 and the active device 2 and between the voltage regulator 6 and the active device 2 . It also includes a throttle valve arranged between the switching circuit and the voltage regulator 6 . The heater 5, the voltage stabilizer 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com