Connecting device

A technology of connecting device and connecting part, which is applied to cabinets, detachable cabinets, household appliances, etc., can solve the problems of inconvenient disassembly and assembly of material racks and low installation efficiency of material racks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

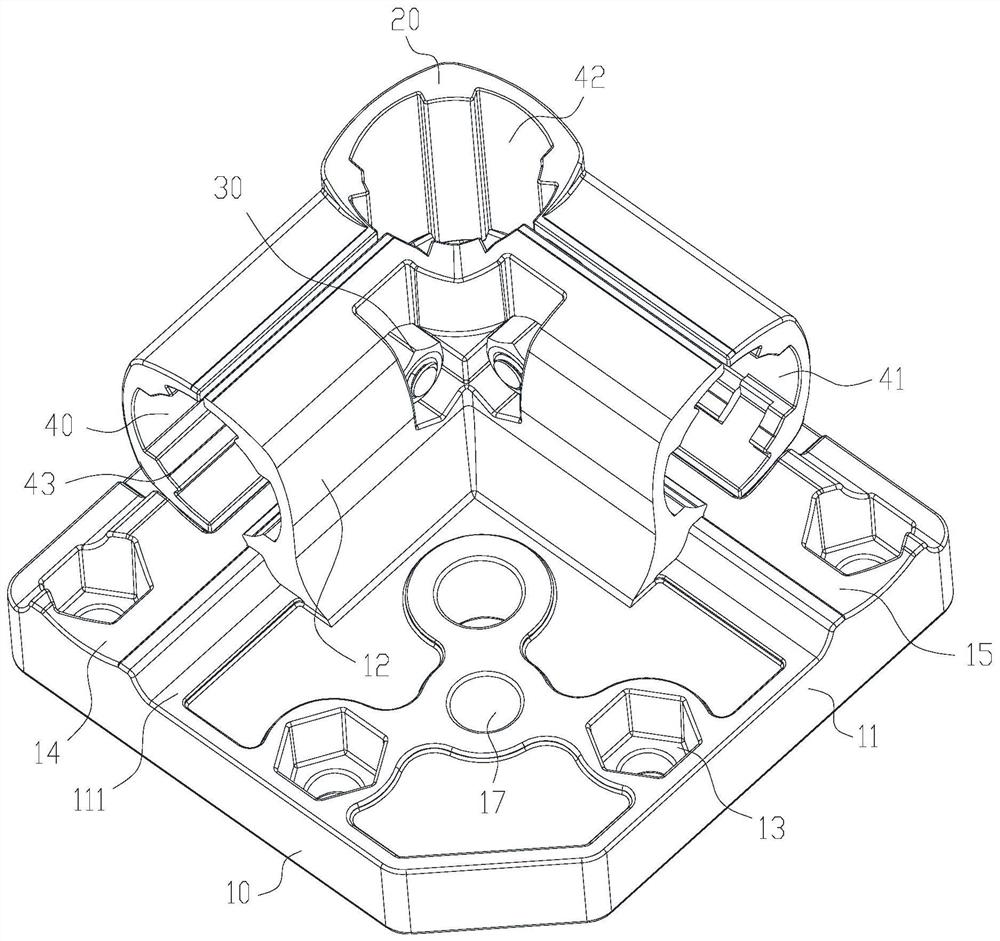

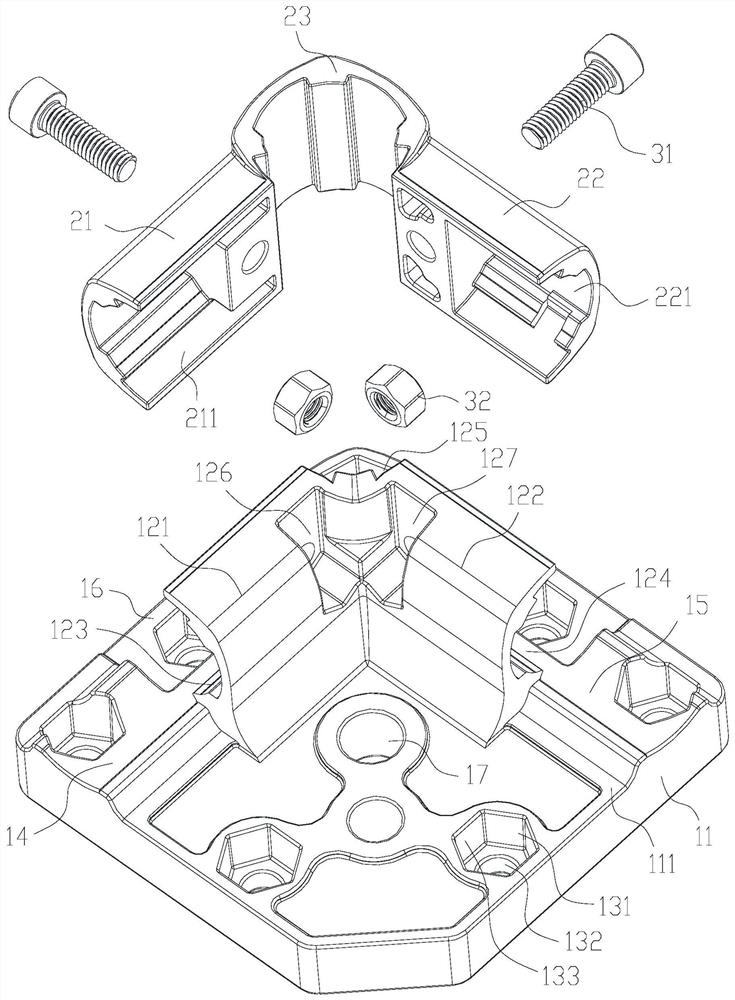

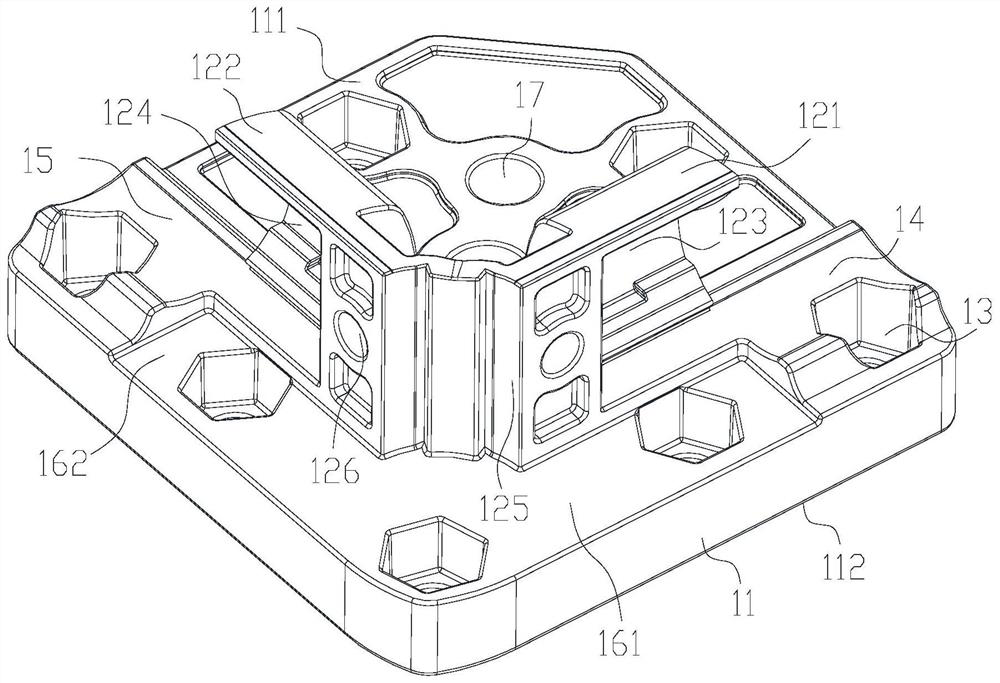

[0032] Examples such as figure 1 , figure 2 and image 3 As shown, the connection device includes: a base 10, an external joint 20 detachably connected to the base 10, and a connection assembly 30. The base 10 includes a board installation part 11 and a profile installation part integrally formed on the board installation part 11 12. The outer joint 20 is closed to the profile installation part 12, and the connection assembly 30 is locked to connect the outer joint 20 and the profile installation part 12, so that the outer joint 20 and the profile installation part 12 are closed to clamp the corresponding type of tubular profile 50. The panel installation part 11 and the profile installation part 12 are integrally formed, with high overall strength and strong coordination. Optionally, the base 10 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com