Multifunctional multi-station clamping jaw structure for automobile overhauls

A multi-station, multi-function technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of prolonged adjustment time, waste of time, and inability to quickly adjust multiple fixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

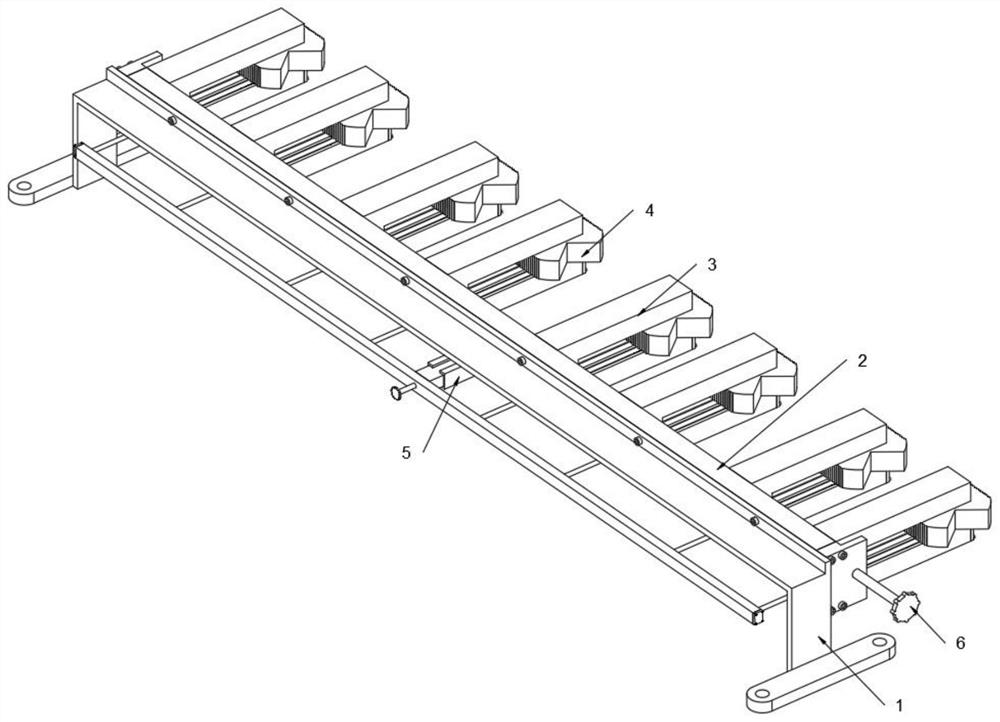

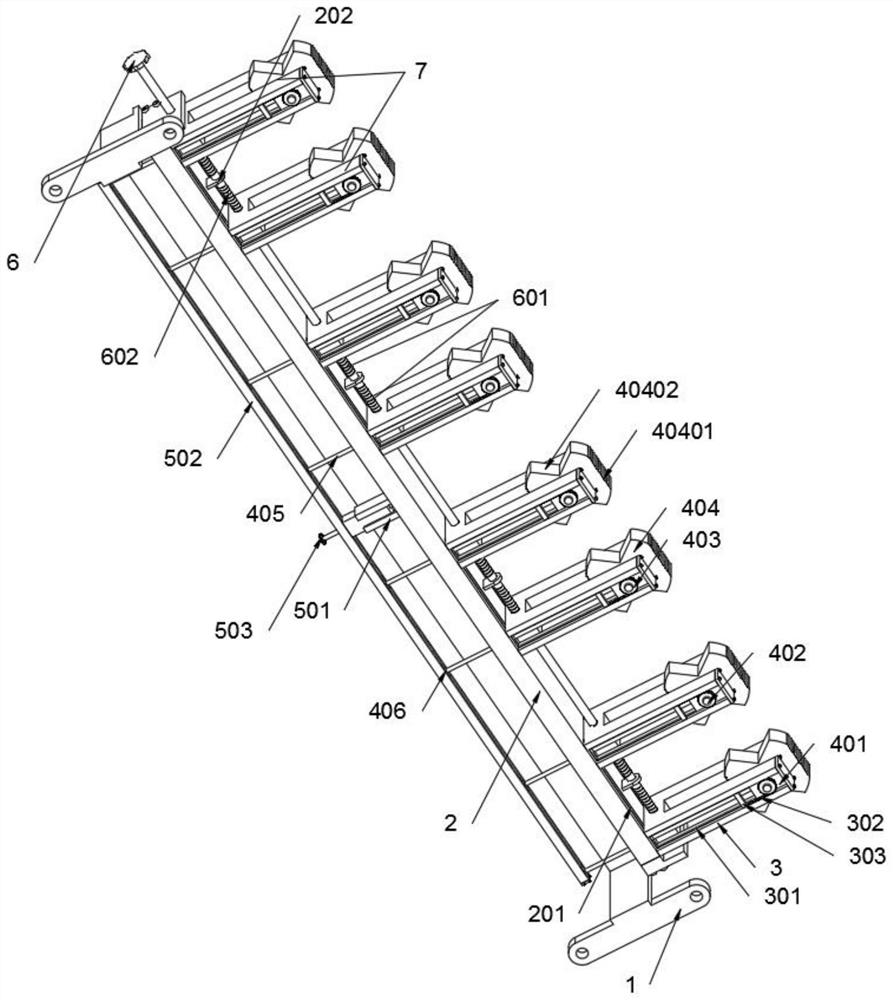

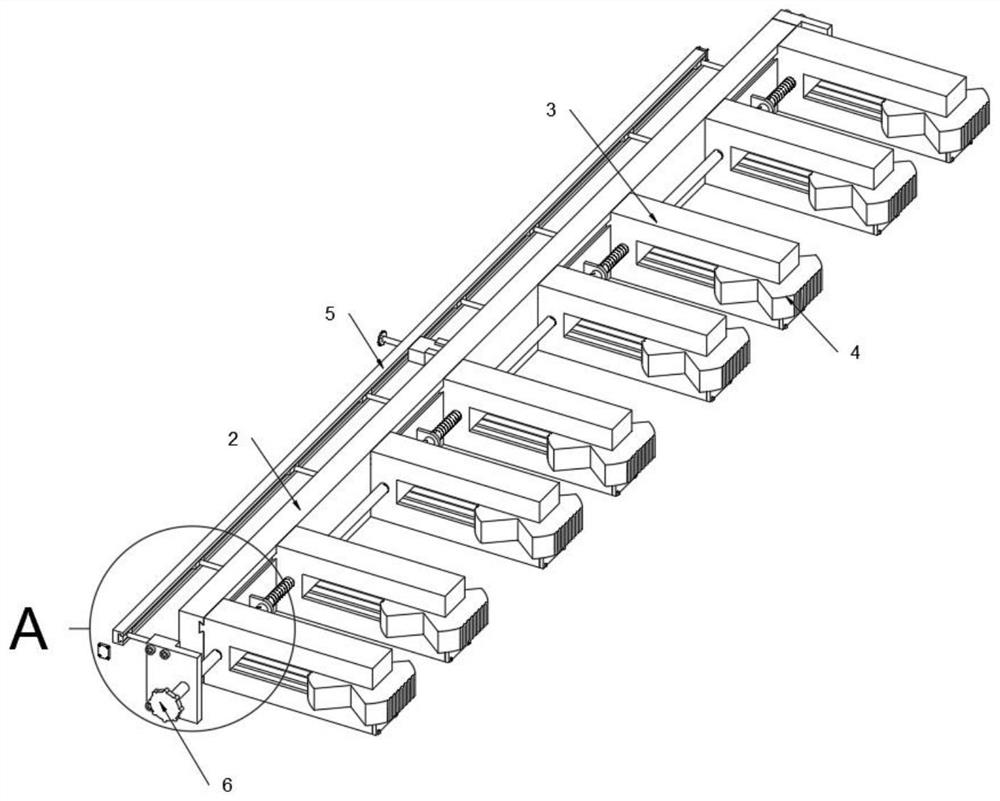

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The present invention provides a multi-station clamping jaw structure for multi-functional automobile maintenance, which includes a fixed seat 1; a sliding seat A2 is fixedly connected to the fixed seat 1 by bolts, and four sets of clamping seats 7 are slidably connected to the sliding seat A2 , and each set of clamping seats 7 is composed of two fixture seats 3; a fixture structure 4 is installed in the fixture seats 3; refer to as Figure 5 and Figure 6 , the sliding seat A2 includes a sliding hole 203, four sliding holes 203 are provided in a rectangular array on the sliding seat A2, and the sliding holes 203 are aligned with the sliding groove A201; the fixture structure 4 also includes a sliding rod 405 and a sliding block 406, The head end of the slide bar 405 is rotatably connected to the rear end face of the main body block 401, and the tail end of the slide bar 405 is welded with a slide block 406; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com