Systems for applying electrically conductive tape traces to substrate and methods of use thereof

A technology of conductive strips and substrates, applied in the direction of circuit substrate materials, conductive pattern formation, printed circuits, etc., can solve problems such as impractical and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

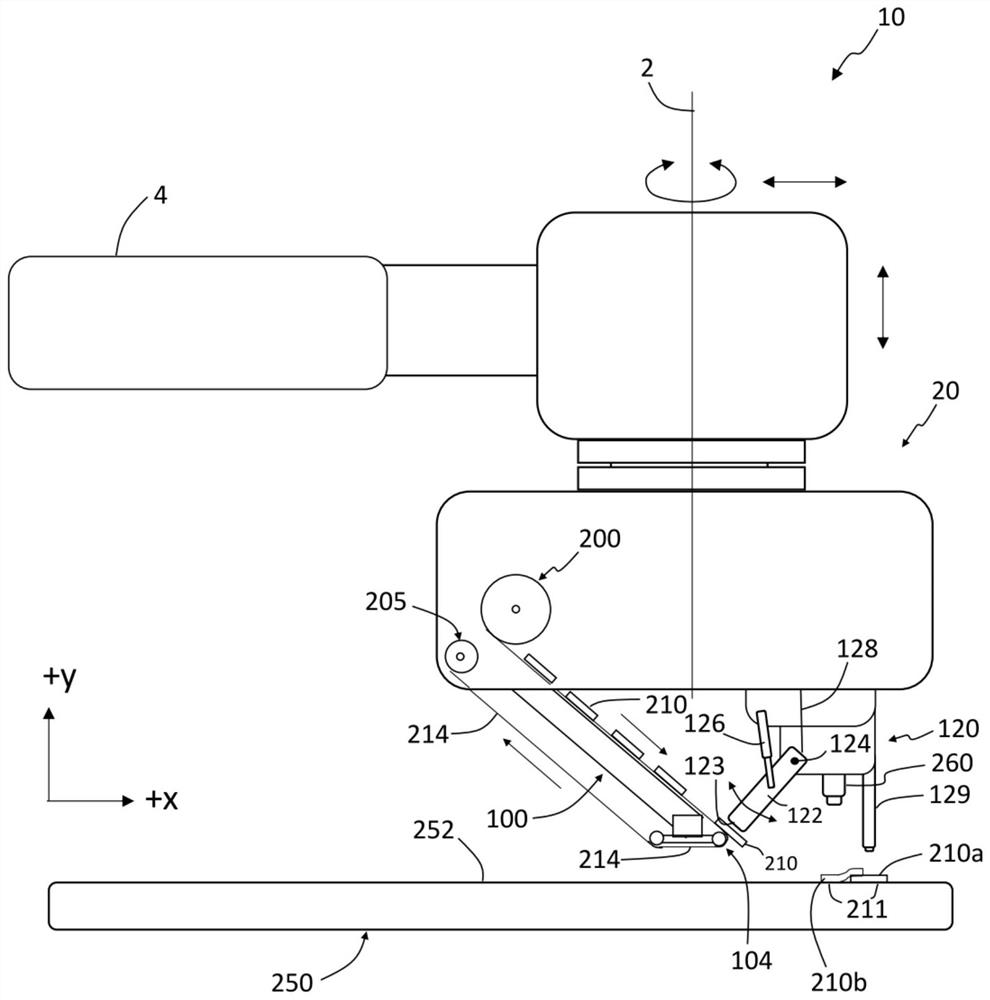

[0027] see now figure 1 , a system 10 for applying conductive tape (referred to herein simply as "conductive tape") and conductive tape traces (referred to herein simply as "conductive tape trace") includes a conductive tape applicator 20 that A segment feeder arm 100 and a segment placement armature 120 are included. In some aspects of the present disclosure, conductive tape applicator 20 includes coating applicator 129 and welder 260, as described in more detail below.

[0028] The conductive tape applicator 20 has at least two degrees of freedom of movement. for example and as figure 1 As schematically depicted in , the conductive tape applicator 20 can move up and down (y-direction), side-to-side (x-direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com