Concrete wall water spray maintenance device

A concrete wall and wall technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of unfavorable water spray maintenance of concrete walls, and achieve the convenience of water spray maintenance, labor saving, and improvement of water spray maintenance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

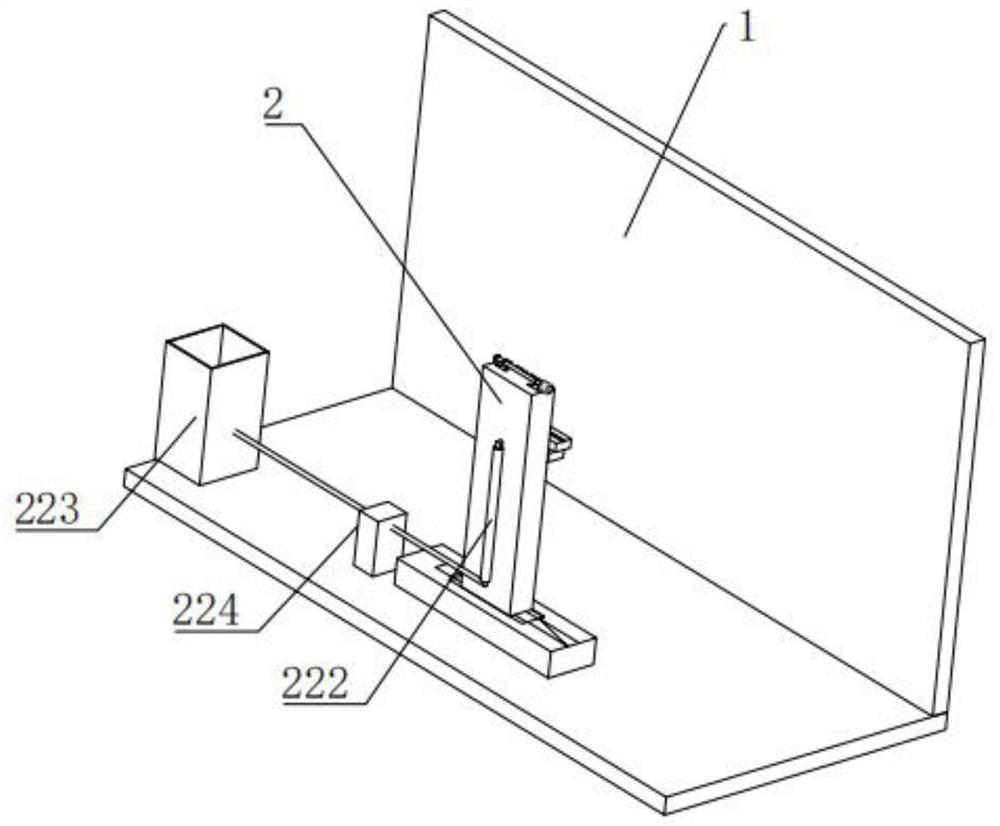

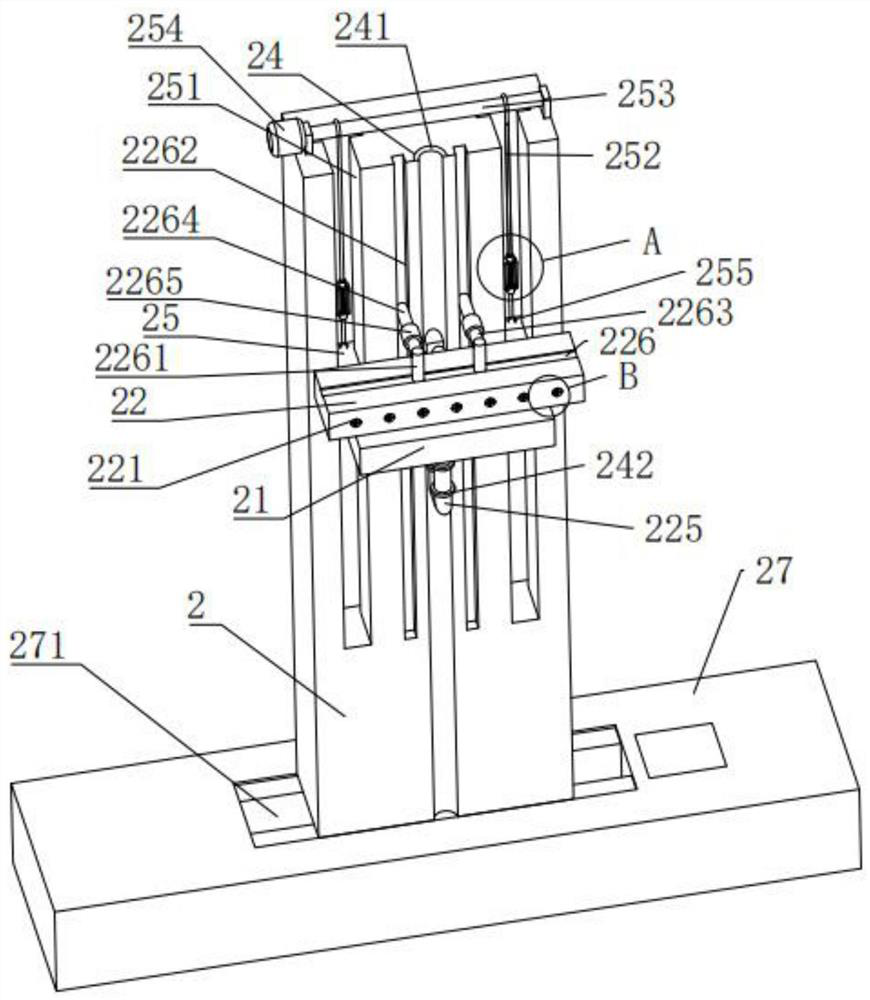

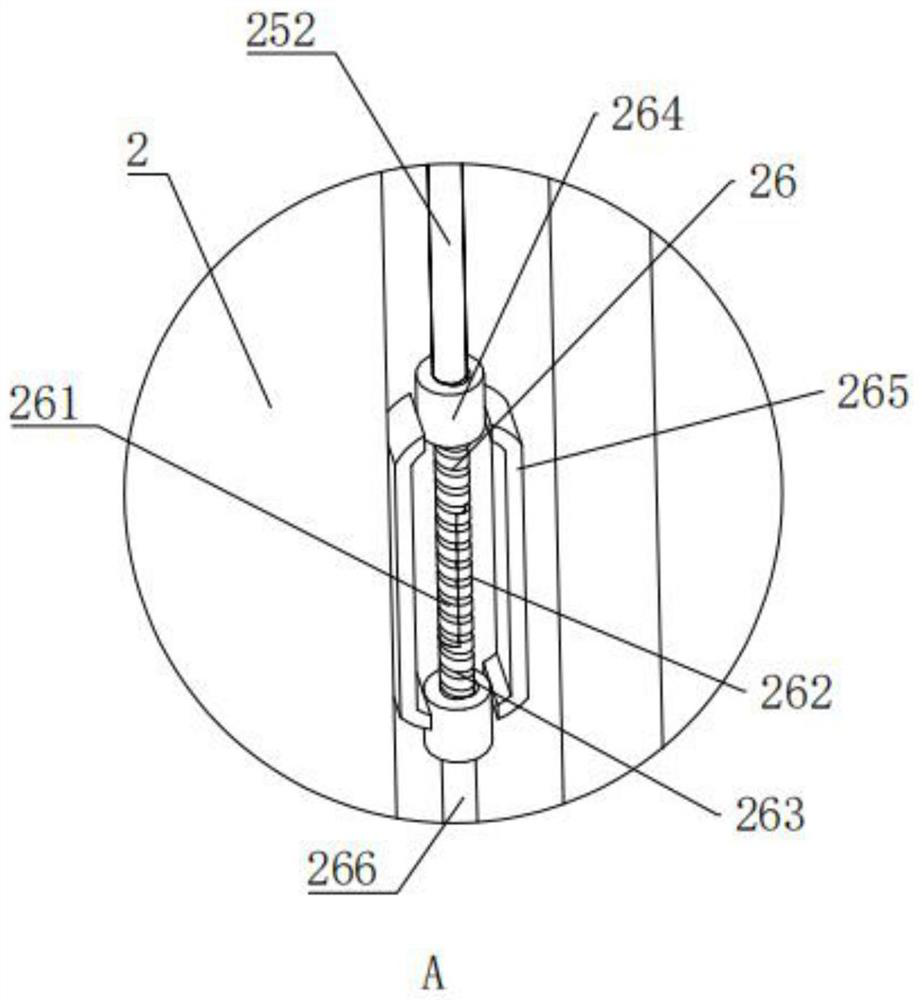

[0026] A concrete wall spray maintenance device, such as figure 1 and figure 2 , including the vertical plate 2 located in front of the wall 1, the vertical plate 2 is slidably connected with the mobile plate 21 along the height direction of the vertical plate 2, that is, the mobile plate 21 can move up and down, and the mobile plate 21 is installed with a Distributed hollow water distribution board 22, the water distribution board 22 is provided with a number of drying holes 221 on the side facing the wall 1, each drying hole 221 is distributed along the length direction of the water distribution board 22, the vertical board 2 is away from the moving board One side of 21 is fixed with a water inlet pipe 222, the upper end of the water inlet pipe 222 passes through the upper end of the vertical plate 2, and a hose 225 is connected to the end of the piercing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com