An electrical connection device with an automatic separation mechanism

An electrical connection device and automatic separation technology, which is applied to the parts, connections, and coupling devices of the connection device, can solve problems such as prolonging the launch time of weapons, and achieve the effects of saving launch time, improving efficiency, and reducing power supply requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

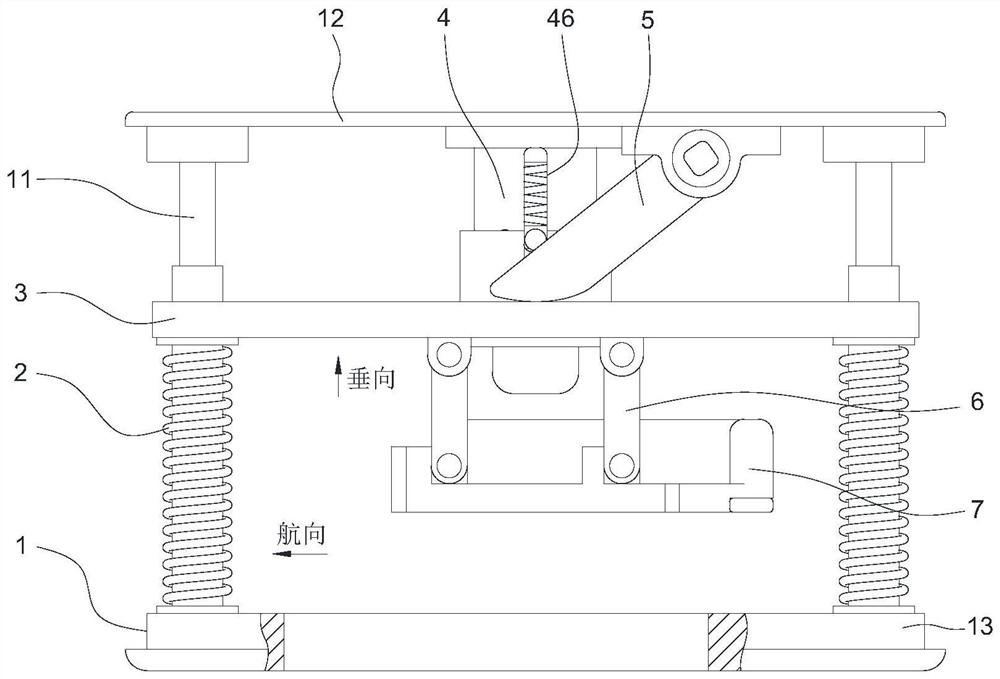

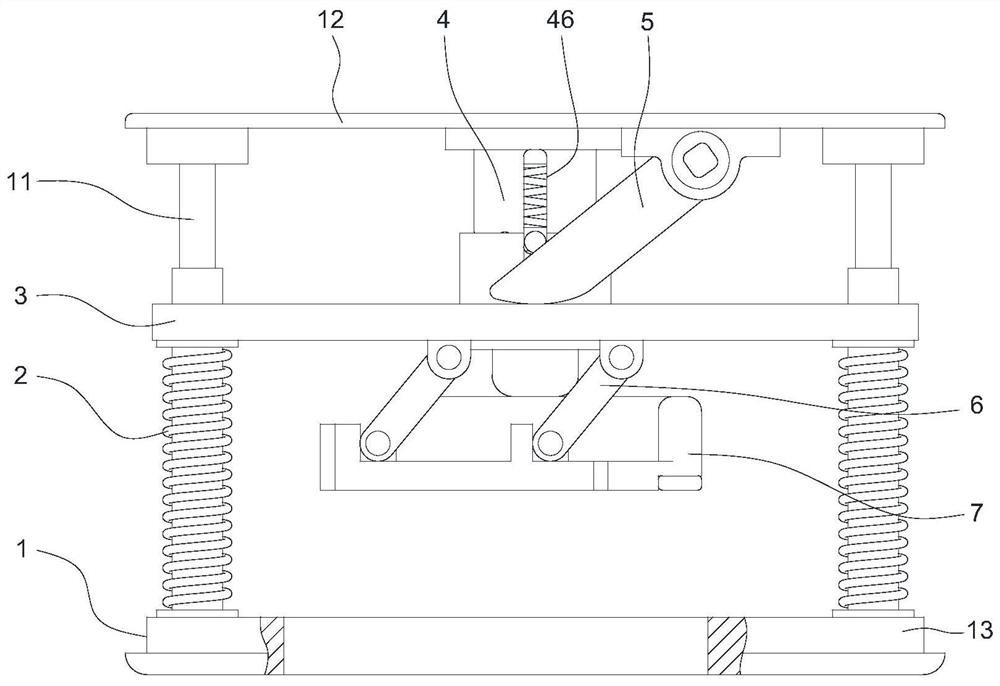

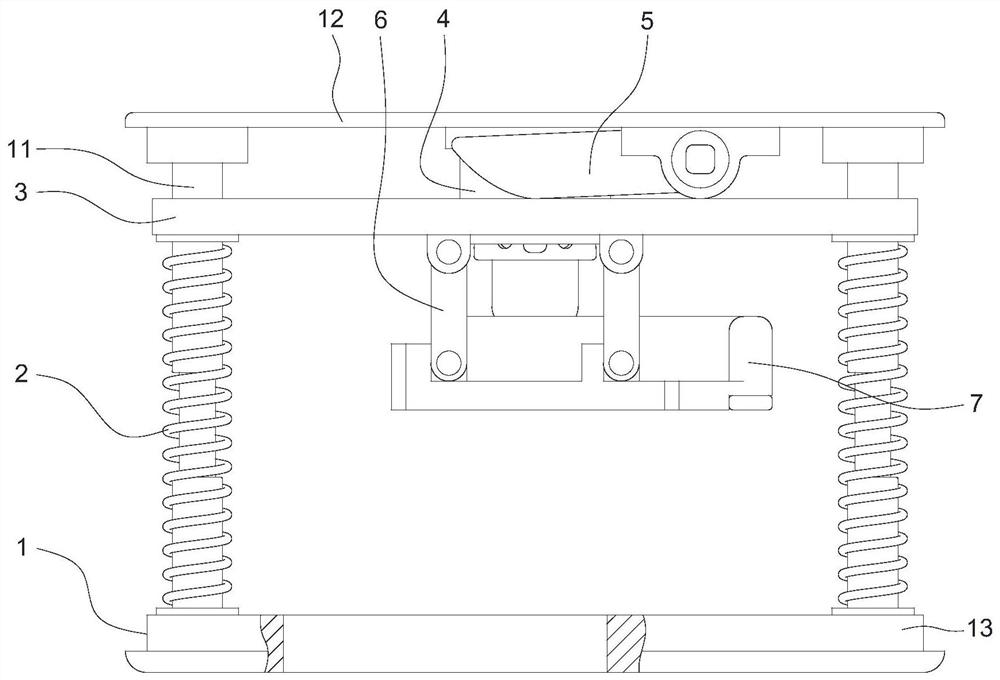

[0025] Such as Figure 1 to Figure 7 As shown, an electrical connection device with an automatic separation mechanism includes an electrical connector and an automatic separation mechanism. The automatic separation mechanism includes a bracket 1, a floating plate 3, a locking mechanism 4, a connecting rod 6 and a mounting shell 7, and the bracket 1 It includes a top plate 12 and a bottom plate 13. The top plate 12 and the bottom plate 13 are fixedly connected by a guide rod 11. The axial direction of the guide rod 11 is perpendicular to the course of the missile body. The axial direction of the guide rod 11 is generally called vertical in the industry. The floating plate 3 slides Set on the guide rod 11, the guide rod 11 is set with a separation spring 2, the separation spring 2 is located between the floating plate 3 and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com