Auxiliary welding tool clamp

A tooling fixture and auxiliary welding technology, which is applied in the field of welding tooling fixtures, can solve the problems of low production efficiency and large manpower consumption, and achieve the effects of improving welding efficiency, friction, welding precision and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

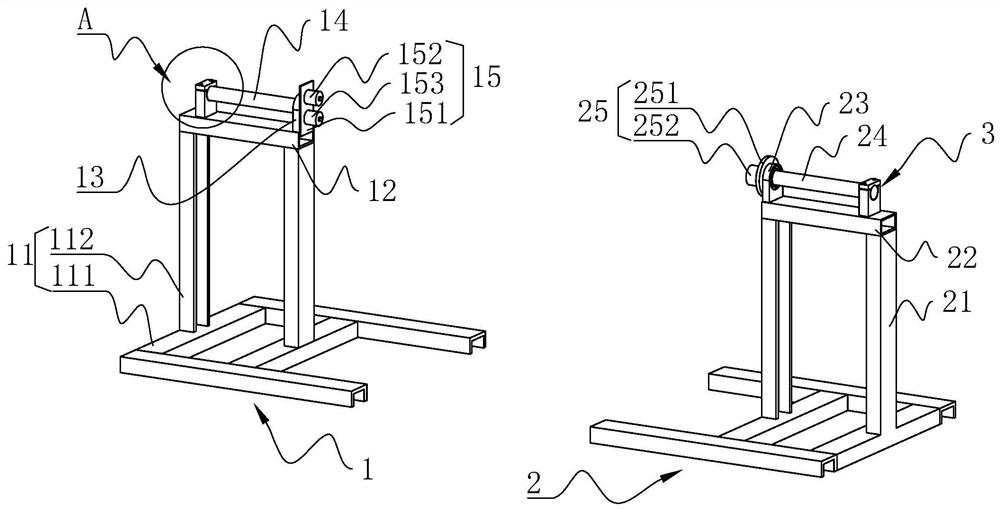

[0034] Reference figure 1 with figure 2 , An auxiliary welding fixture, comprising a left support assembly 1 and a right support assembly 2. The left support assembly 1 includes a left support frame 11, the left support frame 11 is welded with a cuboid-shaped left mounting plate 12, and the left mounting plate 12 is welded There is a left bearing seat 13, a first rotating shaft 14 is installed in the left bearing seat 13, and one end of the first rotating shaft 14 close to the right support assembly 2 is fixedly provided with a first clamping portion 15 for clamping with a welding tool.

[0035] The right support assembly 2 includes a right support frame 21, a rectangular right mounting plate 22 is welded on the right support frame 21, a right bearing seat 23 is welded to the right mounting plate 22, and a second rotating shaft 24 is rotatably installed in the right bearing seat 23 , An end of the second rotating shaft 24 close to the left support assembly 1 is fixedly provided w...

Embodiment 2

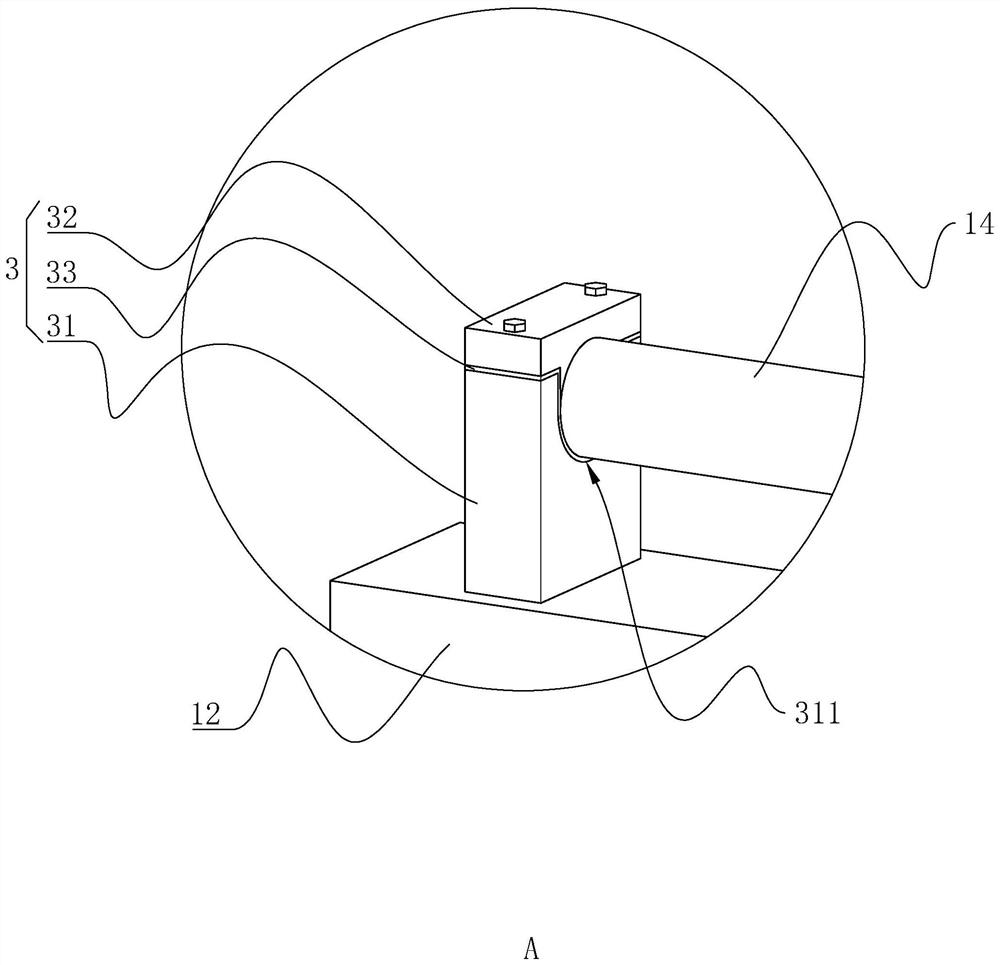

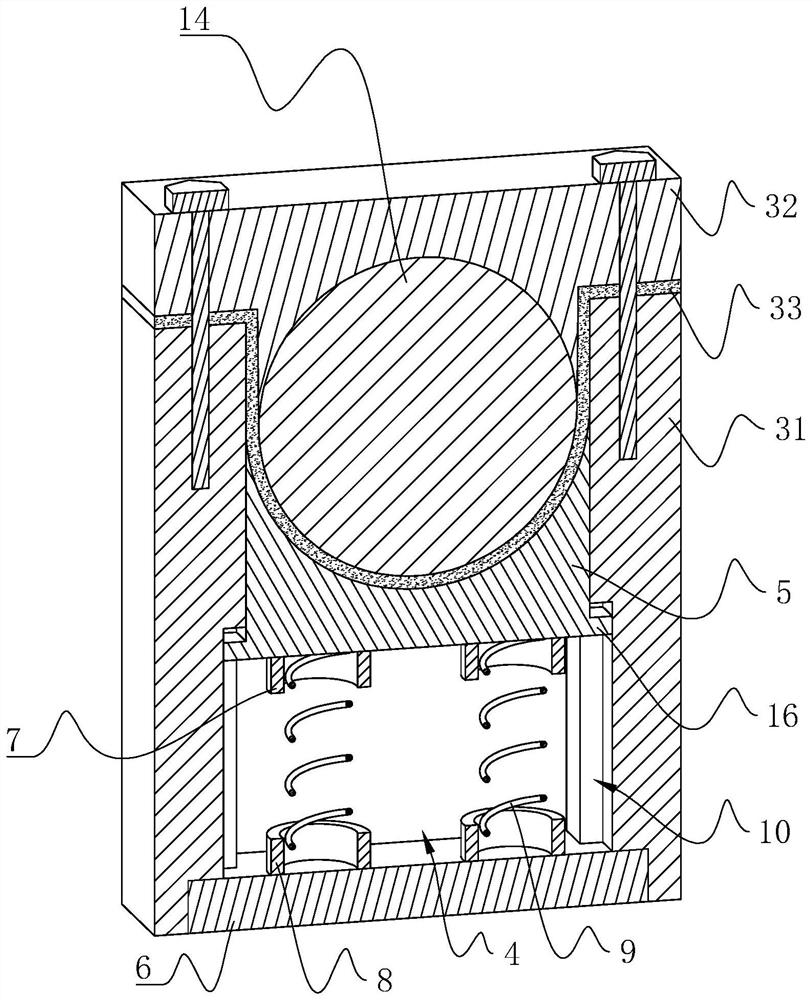

[0043] Reference figure 1 with image 3 The difference between this embodiment and embodiment 1 is that the support block 31 is mounted on the left mounting plate 12 and the right mounting plate 22 by bolts, and the support block 31 is provided with a square chute 4 at one end away from the support groove 311, The bottom of the sliding groove 4 is in communication with the supporting groove 311, a square clamping block 5 is slidably installed in the sliding groove 4, the clamping block 5 abuts against the damping block 33, and the end of the clamping block 5 and the damping block 33 In cooperation, a cuboid-shaped end sealing plate is installed at the notch of the sliding groove 4 through bolts.

[0044] An end of the tightening block 5 close to the end sealing plate is formed with an annular upper ring sleeve 7, and an end of the end sealing plate close to the tightening block 5 is formed with a lower ring sleeve 8 having the same shape as the upper ring sleeve 7. A tightening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com