Ultrahigh-pressure omnidirectional dynamic joint

An ultra-high pressure and dynamic technology, applied in the direction of pipes/pipe joints/pipes, adjustable connections, passing elements, etc., it can solve the problems affecting the cutting effect of the cutting head displacement, and achieve the effect of flexible rotation, reliable structure and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

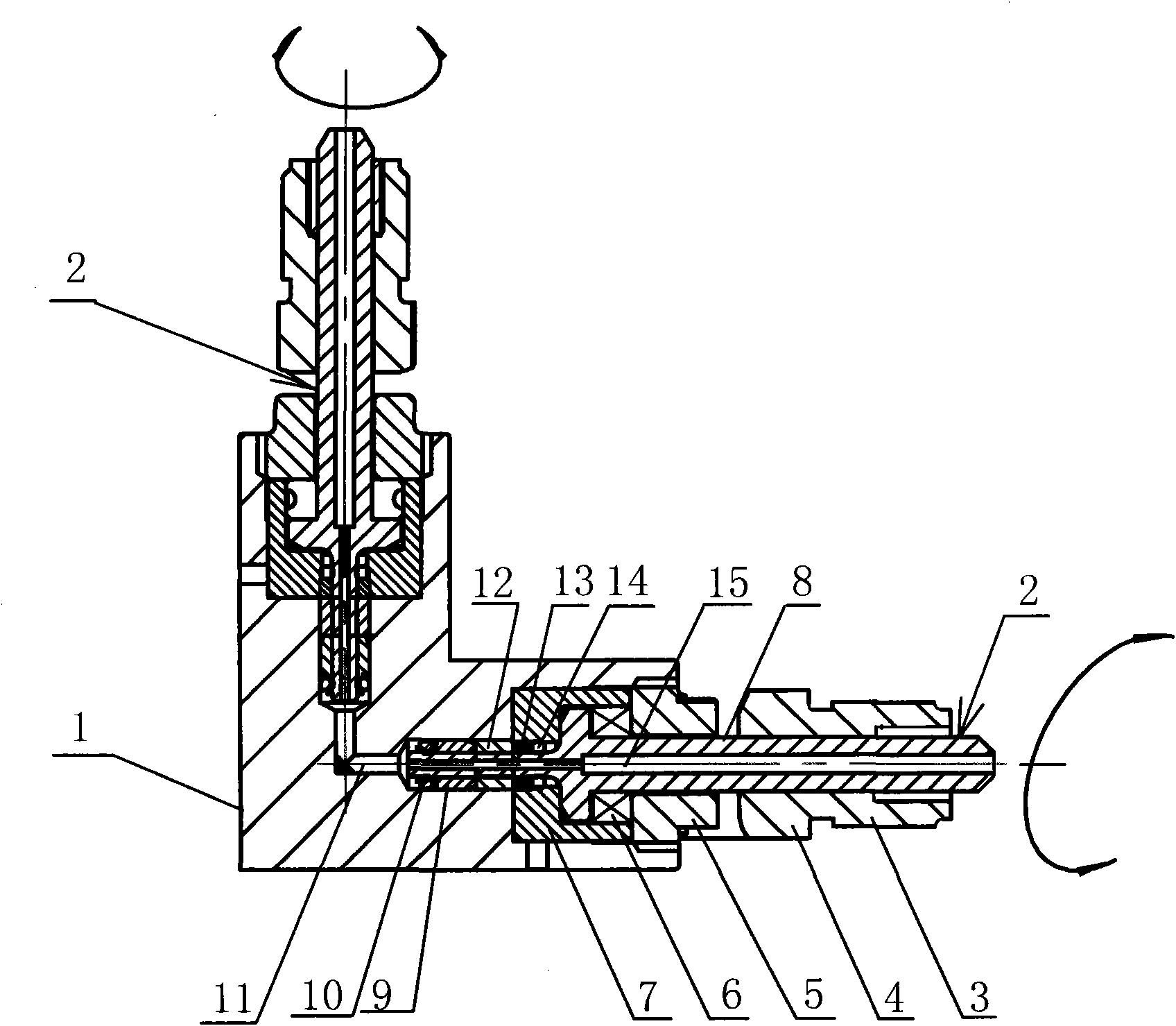

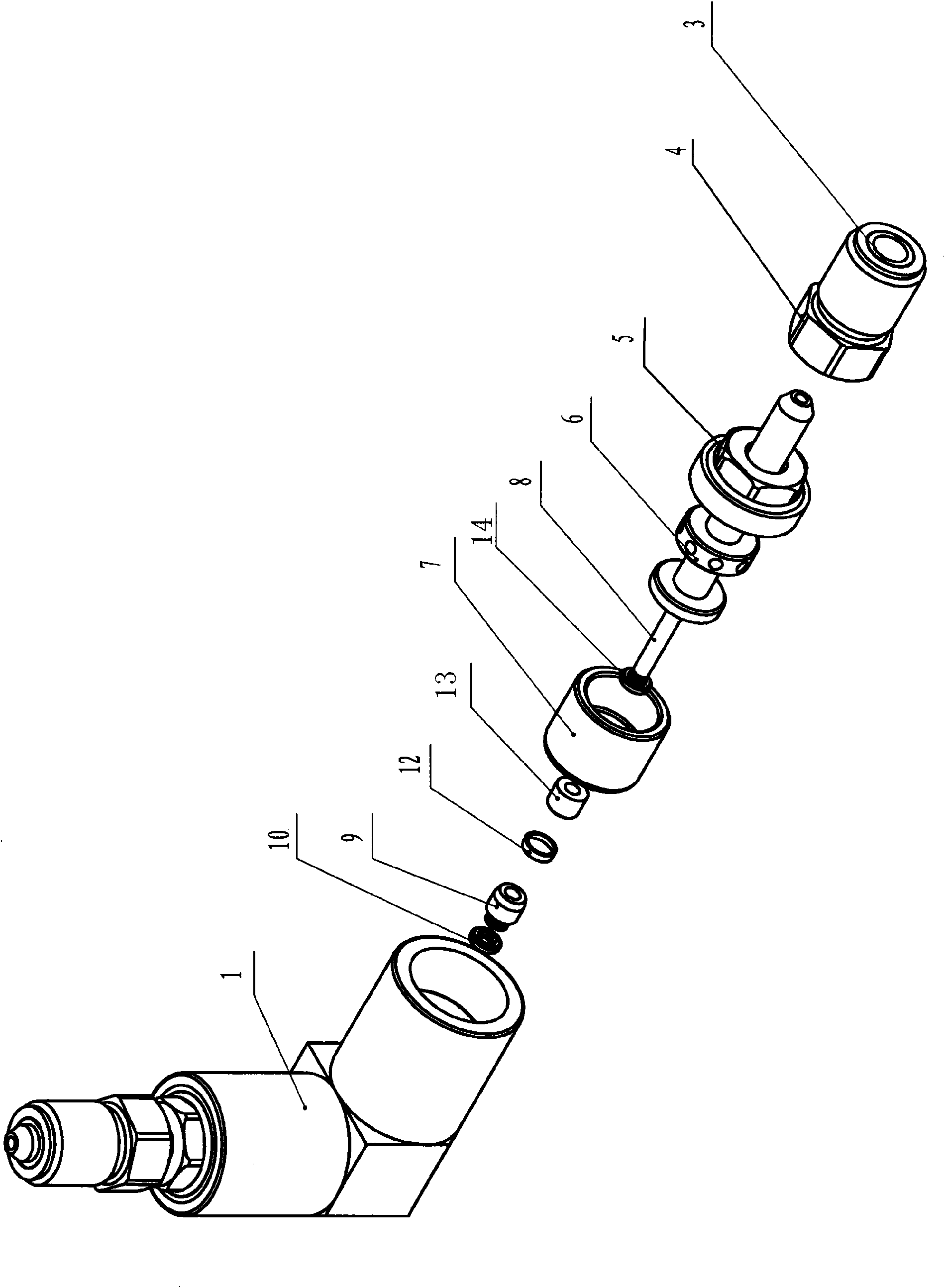

[0009] The ultra-high pressure 360° dynamic joint includes a rotary valve body 1 and a rotary shaft assembly 2. The rotary valve body 1 has an angular structure, and there are communication holes 11 in the cavities at both ends. The rotary shaft 8 in the rotary shaft assembly 2 has a through hole 15. The front end of the rotary shaft 8 is fitted with an O-ring 14, a bearing housing 7, Gasket 13, guide ring 12, pressure ring 9, O-ring 10. The rear end of the rotating shaft 8 is sleeved with a bearing 6 and a lock nut 5 to form the rotating shaft assembly 2 . A series of parts constituting the rotating shaft assembly 2 are pressed into the cavity of the rotating valve body 1 with the lock nut 5, and are connected with the internal thread of the rotating valve body 1 to fix the set parts thereof. The screw plug 4 and the screw sleeve 3 are connected to the external pipeline to form an ultra-high pressure 360° dynamic joint.

[0010] After the dynamic joint bears the fluid press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com