A concrete automatic pumping feeding system

A feeding system and concrete technology, applied in the direction of mixing operation control, clay preparation device, ceramic molding machine, etc., can solve the problems such as inability to conveniently adjust the pouring angle, replenishment of insufficient watering parts, insufficient concrete pouring, etc. , to achieve the effect of simple structure, shortened pouring time and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

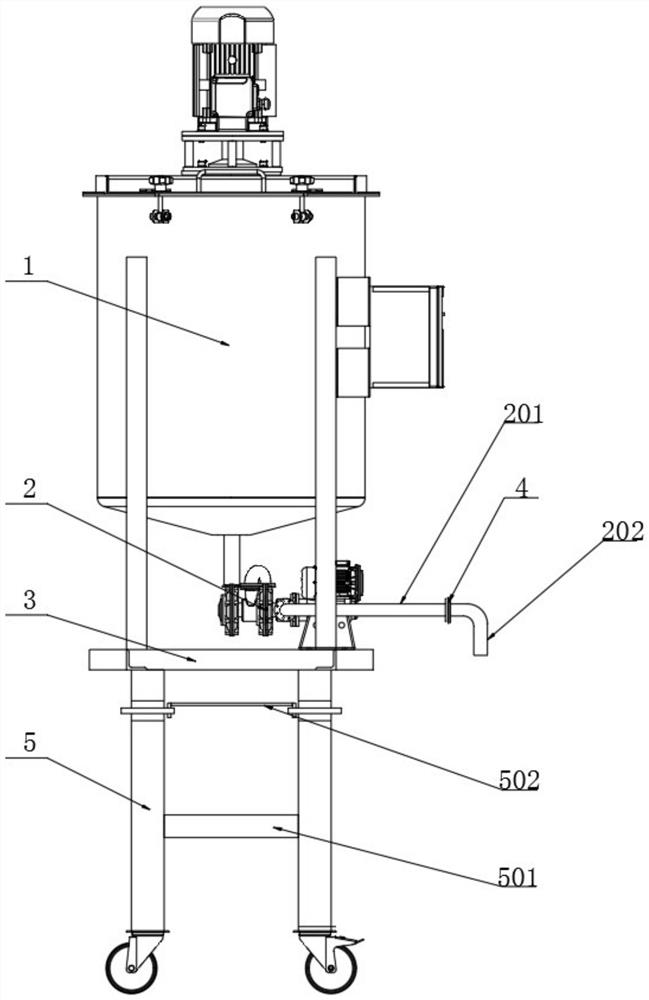

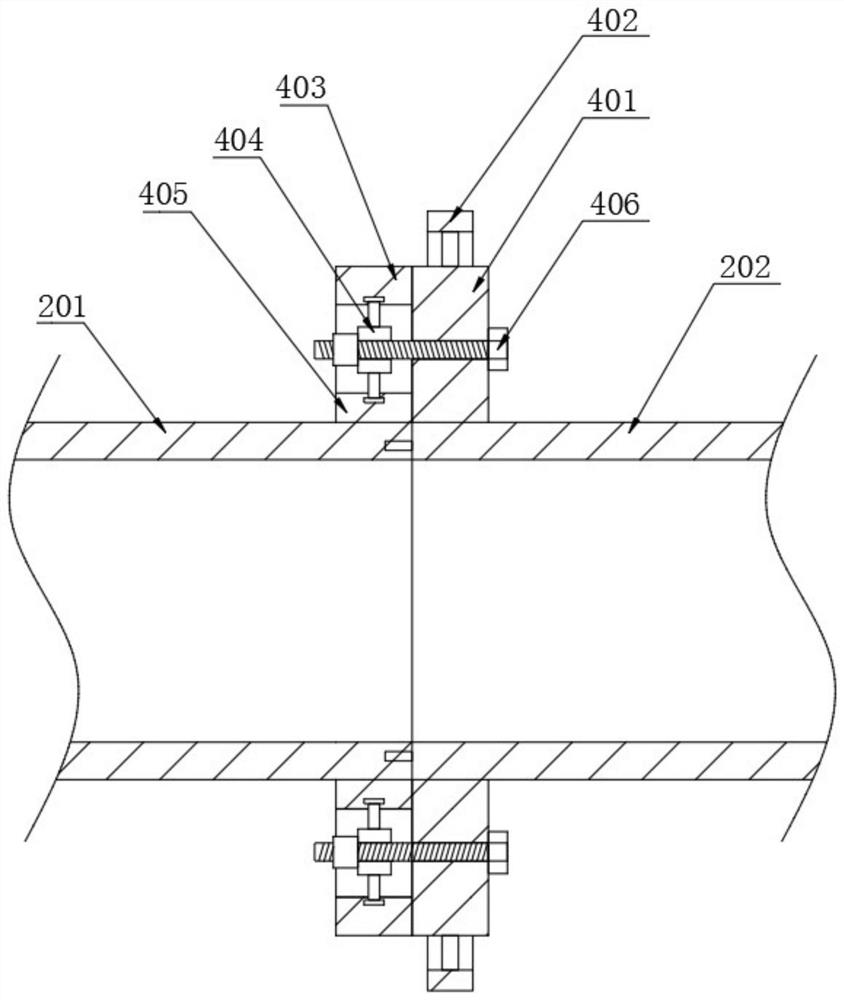

[0030] Such as Figure 1-5 As shown, a concrete automatic pumping and feeding system includes a concrete mixing mechanism 1, a pump body 2 and a mounting bracket 3, the concrete mixing mechanism 1 and the pump body 2 are located on the mounting bracket 3, and the output end of the concrete mixing mechanism 1 Connected to the input end of the pump body 2, the output end of the pump body 2 is connected to the delivery pipe 201, and the delivery pipe 201 is connected to the feeding pipe 202 through the angle adjustment mechanism 4, and several height adjustment mechanisms are connected to the lower end of the mounting bracket 3 5;

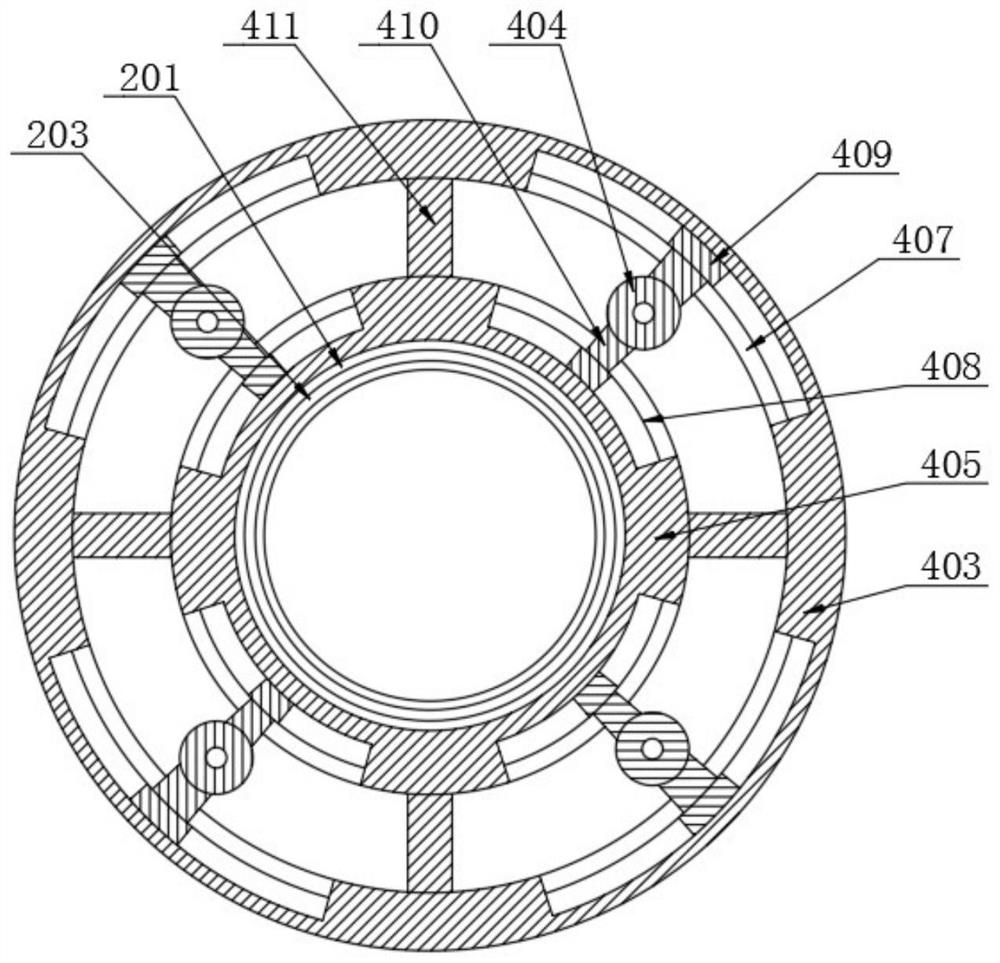

[0031] The angle adjustment mechanism 4 includes an inner ring 405 connected to the outer wall of the delivery pipe 201, several first connecting rods 411 connected to the outer ring 403, an outer ring 403 connected to one end of the first connecting rod 411, and a plurality of first connecting rods 411 connected to the outer ring 403. and several mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap