A cardboard crease processing device

A processing device and cardboard technology, applied in the field of cardboard creases, can solve problems such as cardboard waste, cardboard breakage, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

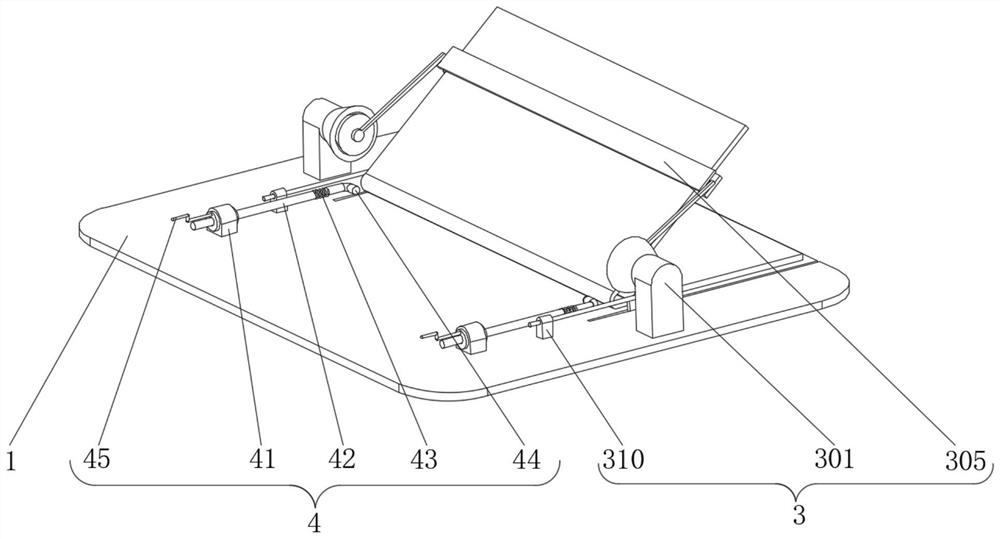

[0021] Example 1, such as Figure 1-4 As shown, the present invention provides a cardboard crease processing device, comprising a backing plate 1 and a paper folding device 3, a paper sheet 2 is placed on the upper surface of the backing plate 1, and a paper folding device 3 is provided on the surface of the paper sheet 2, and the backing plate 1 An adjustment device 4 is provided on the upper surface.

[0022] Let's talk about the concrete setting and function of its folding device 3 and adjusting device 4 in detail below.

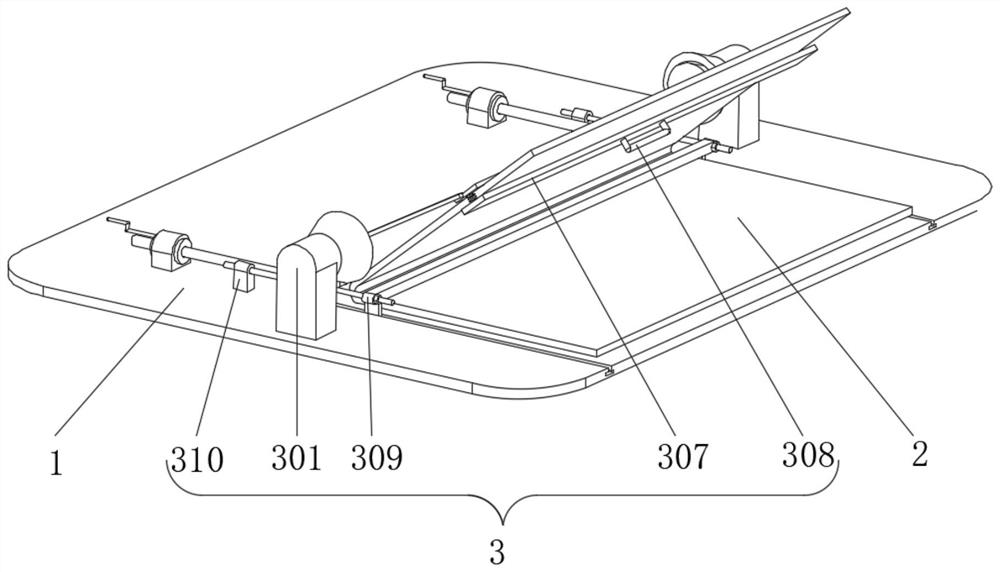

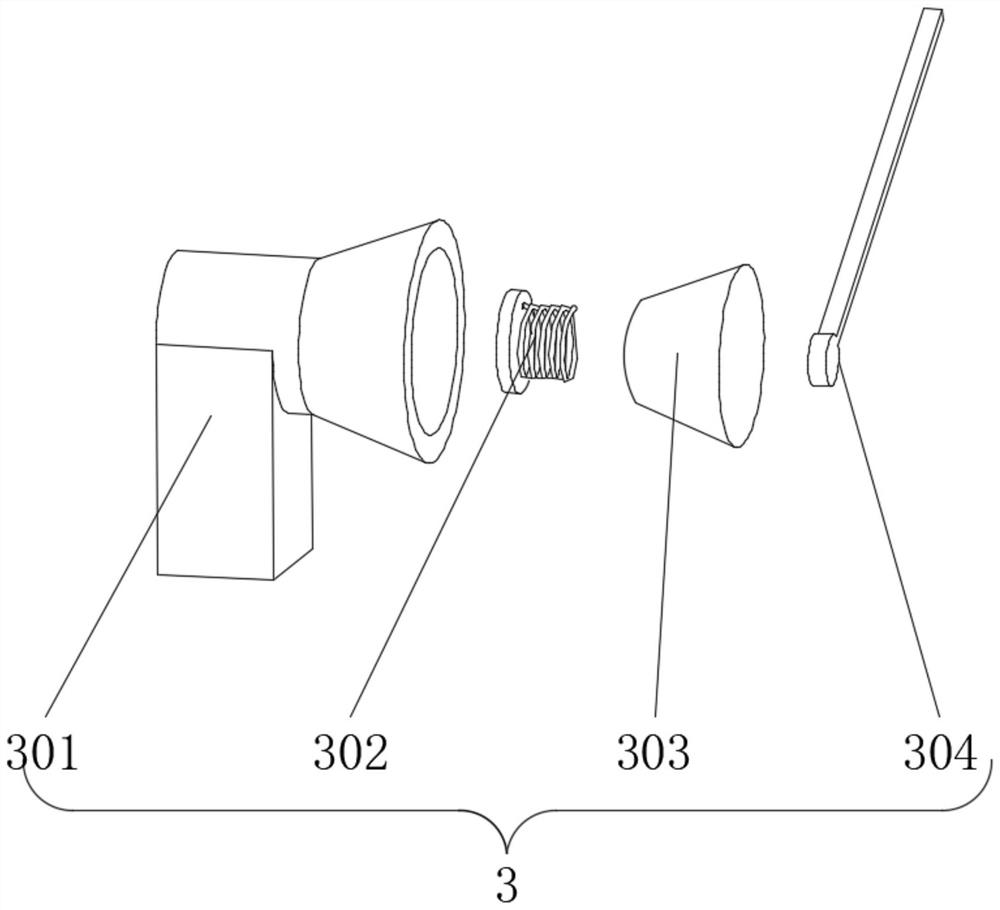

[0023] like figure 2 and image 3 As shown, a cardboard crease processing device includes a backing board 1 and a paper folding device 3, a paper sheet 2 is placed on the upper surface of the backing board 1, and a folding paper device 3 is provided on the surface of the paper sheet 2, and the paper folding device 3 includes a slider 301 , the lower surface of the slider 301 is slidingly connected with the backing plate 1, the inner wall of the table-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com