Fixing structure and fastener thereof

A technology for fixing structures and fixing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

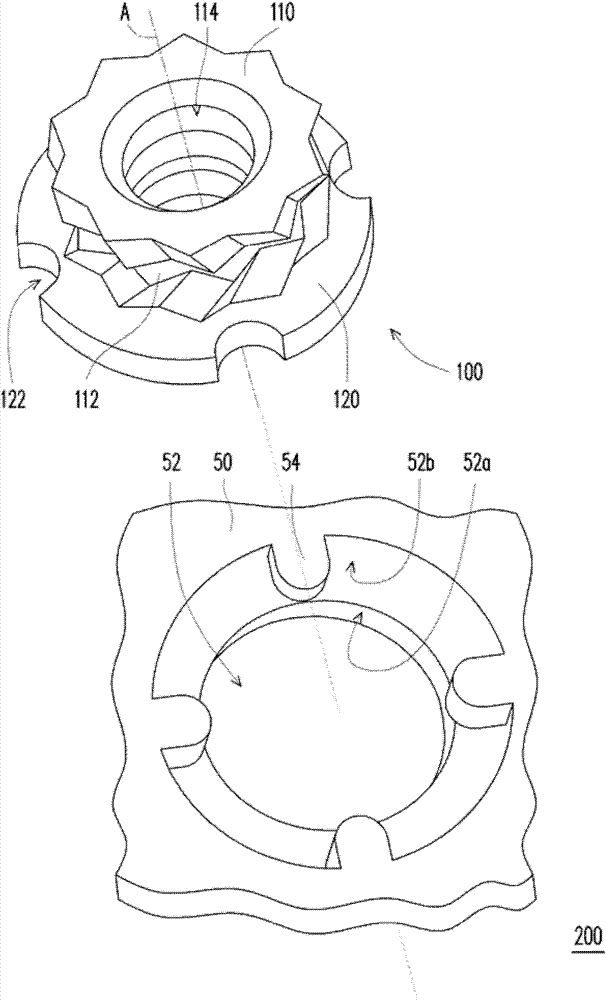

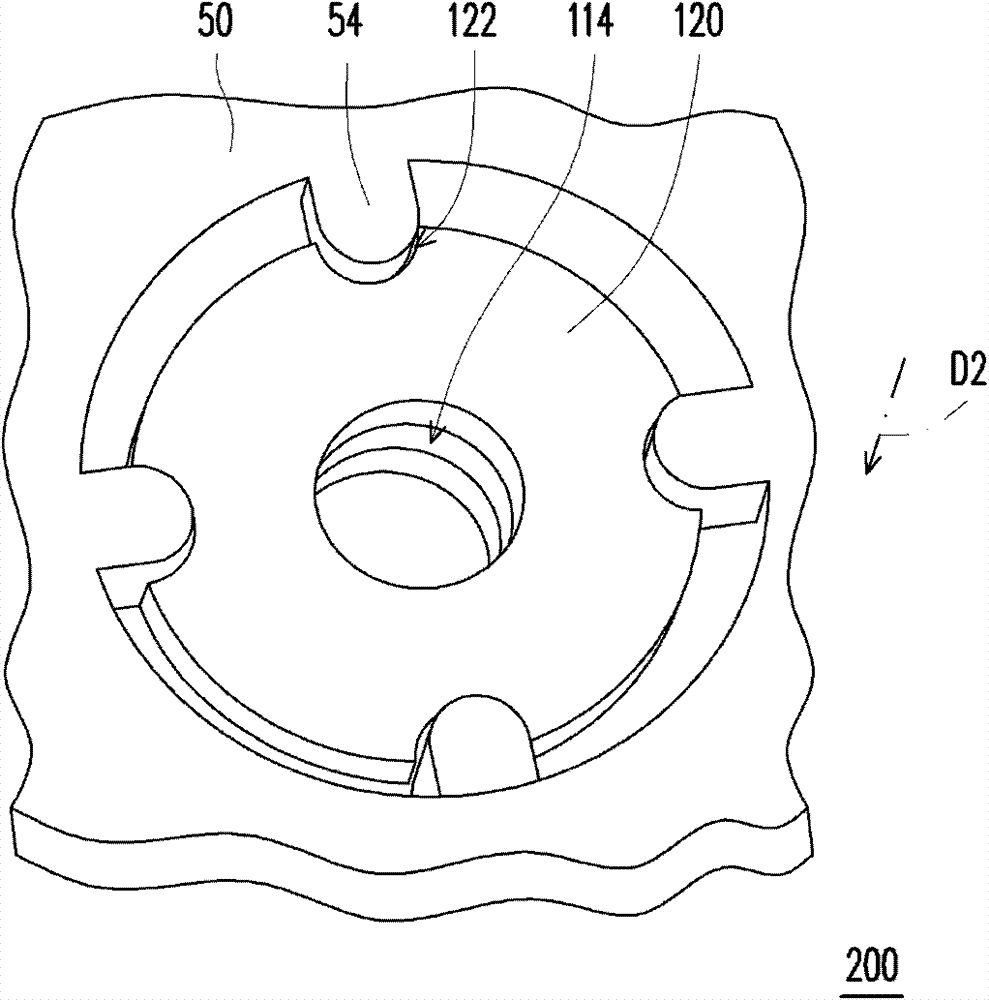

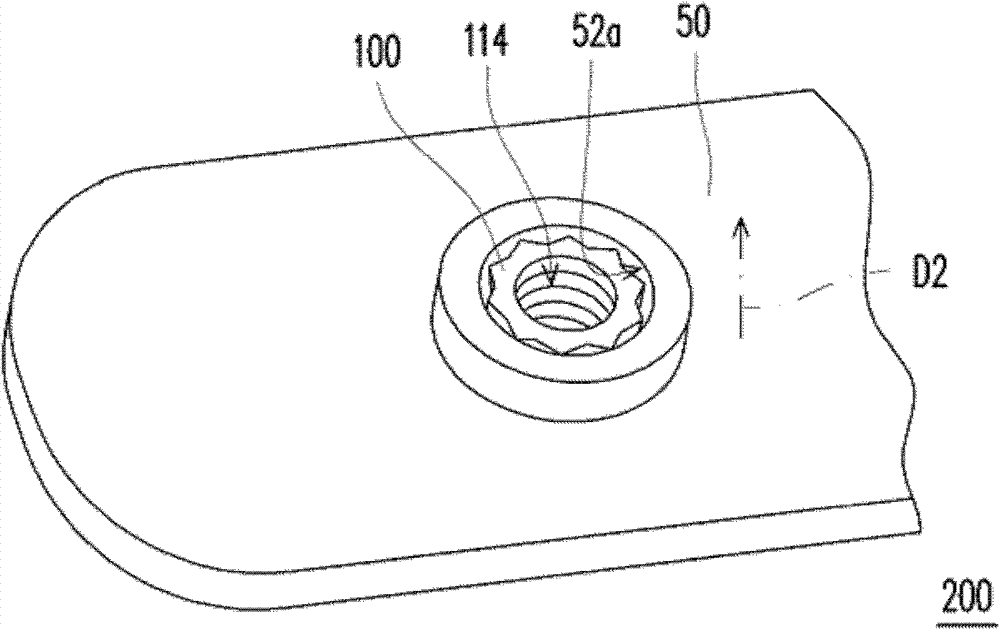

[0034] figure 1 It is an exploded schematic diagram of a fixed structure according to an embodiment of the present invention. Please refer to figure 1 , the fixing structure 200 includes a fixing part 100 and a plate body 50 . The fixing member 100 includes a first step portion 110 and a second step portion 120 . The first stepped portion 110 has a plurality of interference protrusions 112 and a screw hole 114 . The interference protrusions 112 are arranged around the first stepped portion 110 , and the screw holes 114 pass through the first stepped portion 110 . The second stepped portion 120 is fixed to the first stepped portion 110 along an axis A of the screw hole 114 , and the outer dimension of the second stepped portion 120 is larger than the outer dimension of the first stepped portion 110 . In this embodiment, the first stepped portion 110 and the second stepped portion 120 may be approximately cylindrical, and the interference protrusions 112 are arranged around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com