Large ceramic tile stacking method

A technology for slabs and ceramics, applied in the field of ceramic tiles, can solve the problems of high labor intensity, time-consuming and laborious, and achieve the effect of effective stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

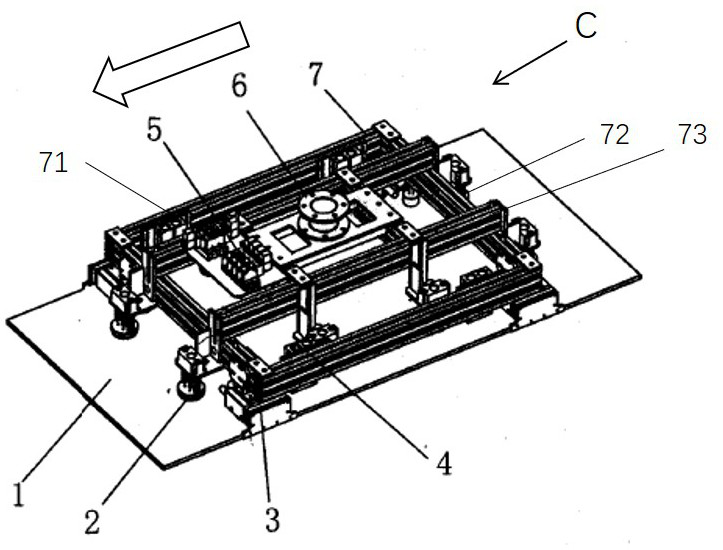

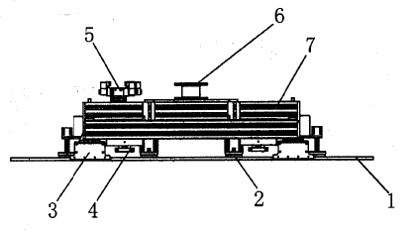

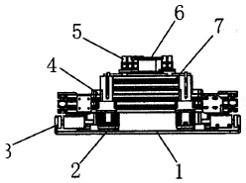

[0049] The present invention will be further described below with reference to the accompanying drawings and the following embodiments. It should be understood that the accompanying drawings and the following embodiments are only used to illustrate the present invention, but not to limit the present invention.

[0050] The invention provides a method for stacking ceramic large slabs, comprising: transporting the ceramic large slabs to a designated position of a conveying wire rack; clamping and adsorbing the ceramic large slabs; making the clamped and adsorbed ceramic large slabs Lift and turn over a specified angle; make the turned over ceramic slab close to the wooden bracket and close to the previously coded ceramic slab; release the clamped and adsorbed ceramic slab and push the ceramic slab Make it abut against the large ceramic tile that has been coded before.

[0051] Figure 1 to Figure 9 An embodiment of the palletizing device used in the method for palletizing ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com