Packed pesticide stacking manipulator

A technology of manipulators and pesticides, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of easy corrosion, high labor intensity, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

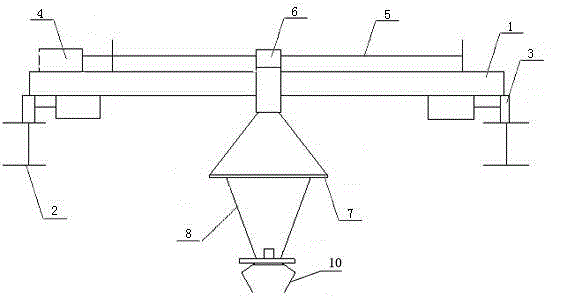

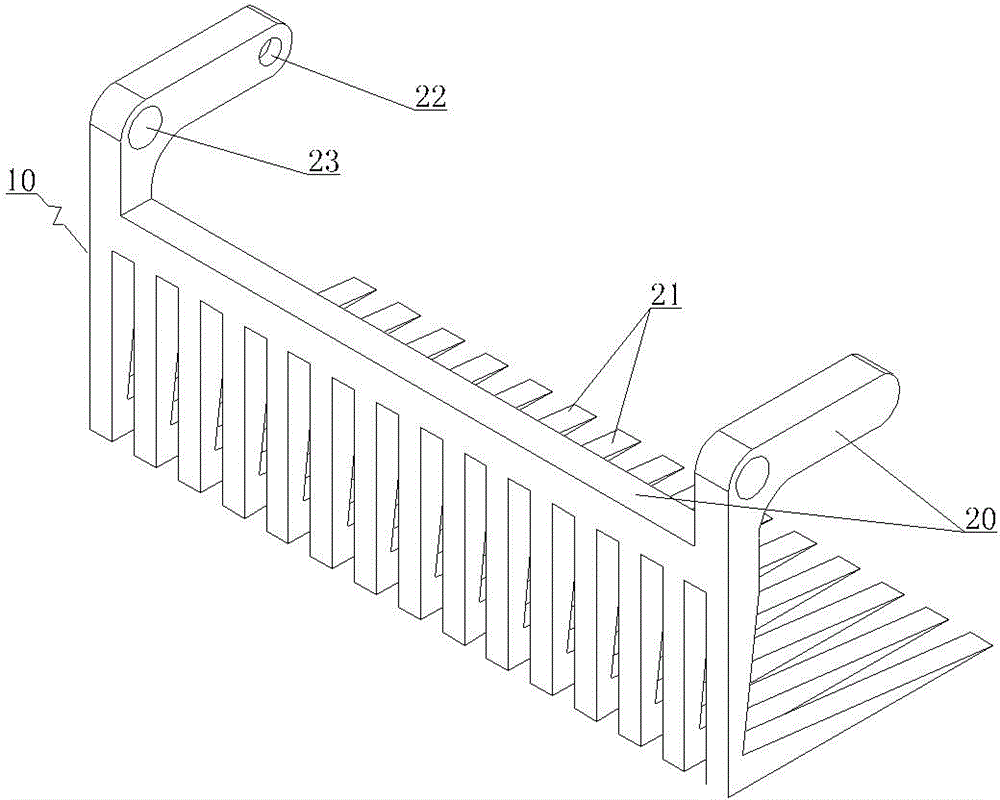

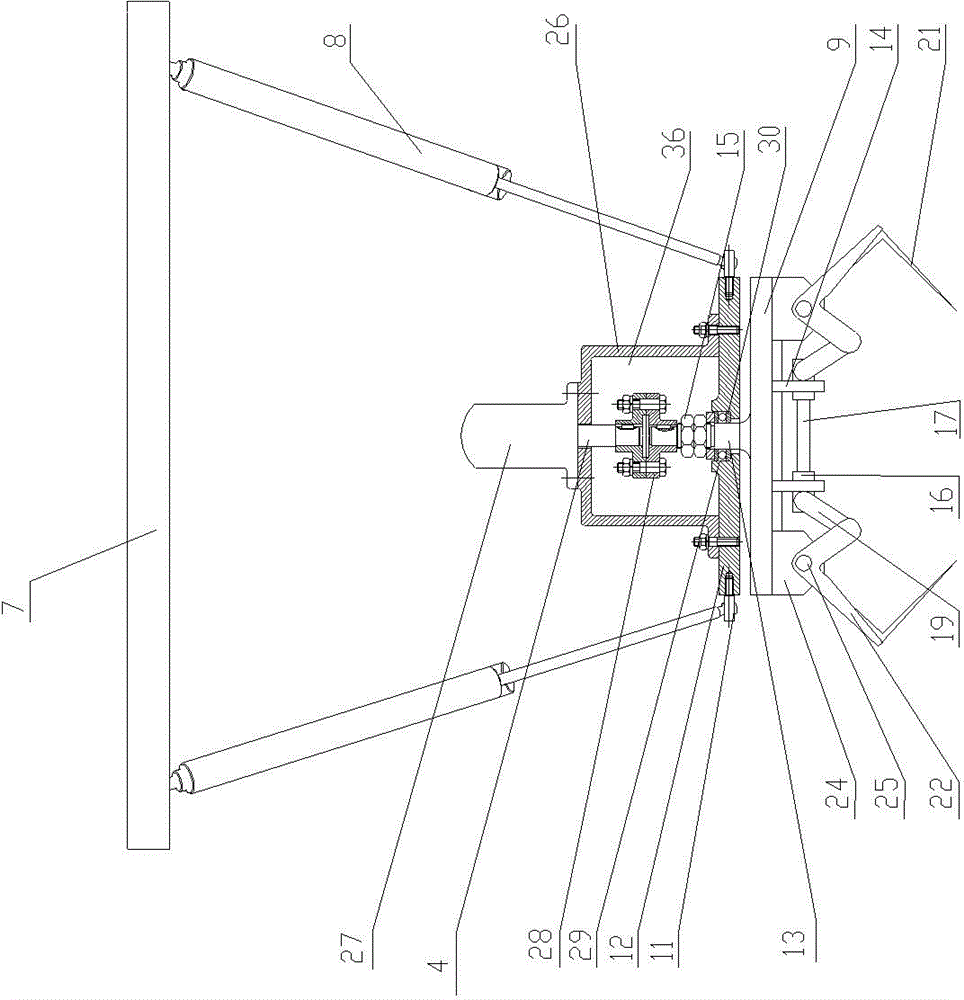

[0017] A boxed pesticide palletizing manipulator, such as Figure 1~Figure 7 : It includes a beam 1 and two guide rails 2 arranged in parallel. The two sides of the beam 1 are respectively supported on the corresponding guide rails 2 through the moving wheels 3. The beam 1 is arranged perpendicular to the guide rails 2. A screw structure is arranged above the beam 1. The screw A moving block 6 is set on the screw rod 5 of the structure, and the lower end of the moving block 6 is set on the beam 1. Fixedly connected to the moving block 6, the telescopic rod 8 is respectively connected to both sides of the bottom surface of the fixed frame 7 through the ball hinge 11. There is a shaft hole, the upper end surface of the panel with shaft 9 is fixed with a central shaft 13, and the lower end surface is protruded with a guide sleeve 14, and the central shaft 13 runs through the shaft hole 29 of the bottom plate 12 from bottom to top, and a positioning nut 15 is set behind the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com