A tube mirror and automatic optical detection equipment

A tube mirror and lens technology, which is applied in the field of automatic optical inspection, can solve the problems that cannot meet the requirements of AOI large field of view, and the tube mirror has a small field of view angle, so as to solve the problem of small field of view, reasonable focal length, and satisfying The effect of resolution requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

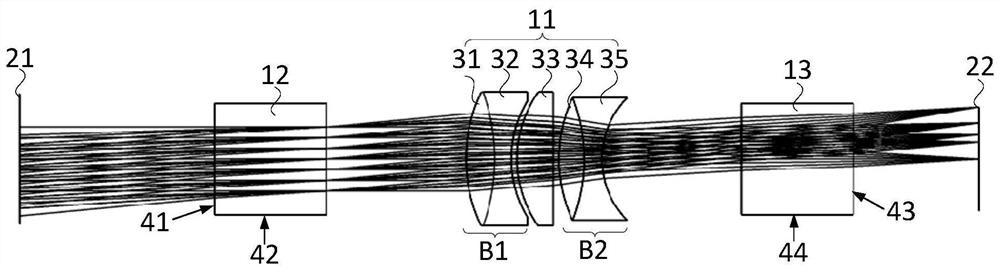

[0050] continue to refer figure 1 , the tube lens provided by Embodiment 1 of the present invention includes a first lens group 11, a second lens group 12, and a third lens group 13, wherein the first lens group 11 can realize large field of view achromatic imaging by cooperating with an infinity-corrected objective lens , the second lens group 12 and the third lens group 13 respectively provide two coaxial interfaces, wherein the second lens group 12 can also be used to connect a coaxial lighting unit or focusing unit in addition to connecting the infinity correction objective lens, and the third lens Group 13 can be connected with two groups of imaging elements or a group of imaging elements and a group of focusing units. The first lens group 11 includes a first lens 31, a second lens 32, a third lens 33, a fourth lens 34 and a fifth lens 35 arranged in sequence from the object plane 21 to the image plane 22 along the optical axis, wherein the first lens 31 and the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com