Control valve

A technology for controlling valves and valve bodies, which is applied in the control of coolant flow, valve details, multi-way valves, etc. It can solve problems such as valve sliding surface wear and achieve the effect of inhibiting early wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, embodiments of the present invention will be described based on the drawings. In the following description, a case where the control valve of the present embodiment is employed in a cooling system for cooling an engine using cooling water will be described.

[0027] [cooling system]

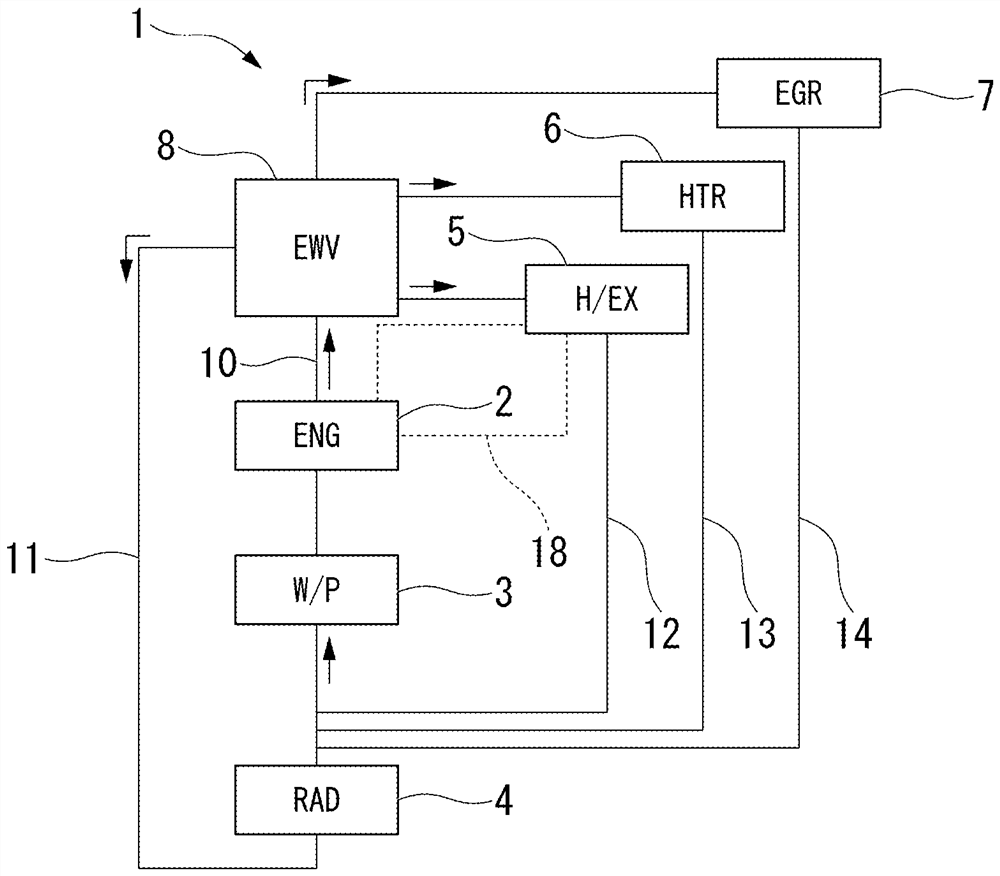

[0028] figure 1 is a block diagram of the cooling system 1.

[0029] Such as figure 1 As shown, the cooling system 1 is mounted on a vehicle having at least an engine as a driving source of the vehicle. In addition, as the vehicle, a hybrid vehicle, a plug-in hybrid vehicle, or the like may be used other than a vehicle having only an engine.

[0030] Cooling system 1 is engine 2 (ENG), water pump 3 (W / P), radiator 4 (RAD), heat exchanger 5 (H / EX), heat core 6 (HTR), EGR cooler 7 (EGR) and the control valve 8 (EWV) are configured by connecting various flow paths 10 to 14 .

[0031] The water pump 3 , the engine 2 , and the control valve 8 are sequentially connected on the main f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com