Filling equipment with function of removing air bubbles

A technology of filling equipment and functions, which is applied in the field of filling equipment with the function of removing air bubbles, can solve the problems of waste of resources, reduction of practicability, liquid overflow, etc., and achieve the effect of good anti-dripping and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

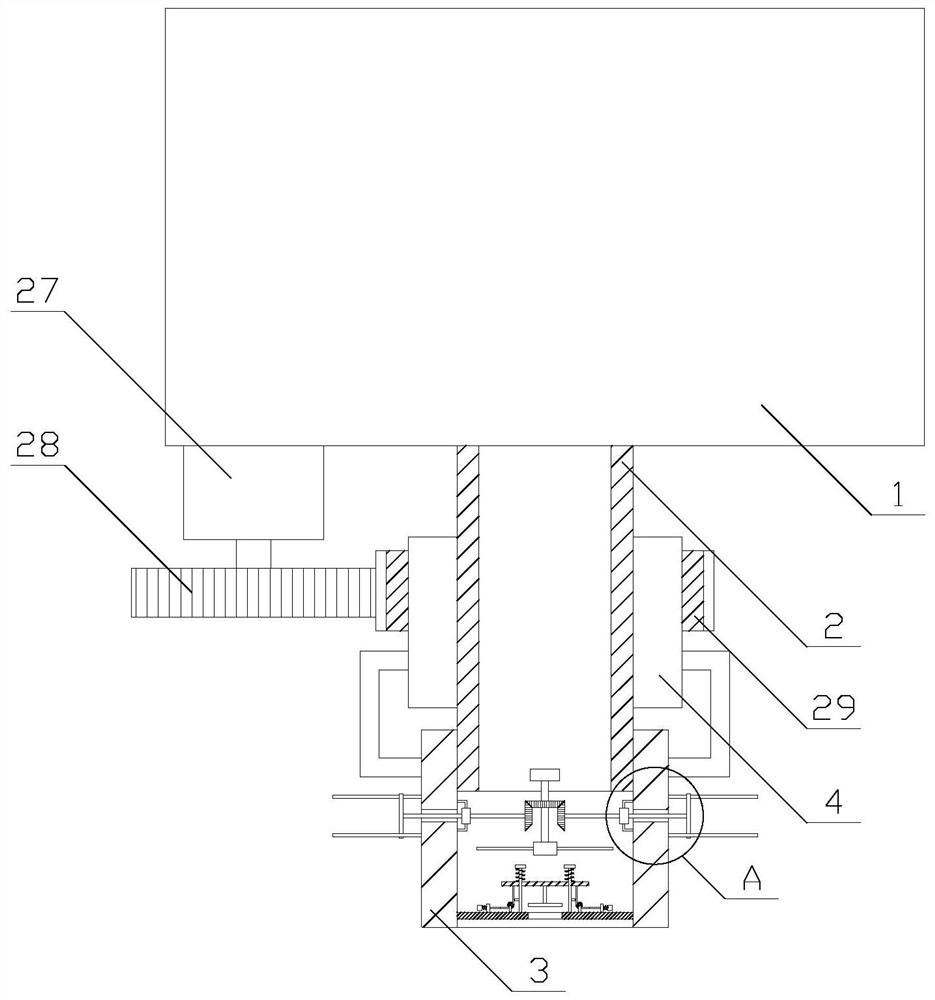

[0028] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] Such as Figure 1-2 所示,一种具有清除气泡功能的灌装设备,包括控制箱1和出料管2,所述出料管2竖向设置在控制箱1的底部,所述控制箱1内设有执行系统,所述出料管2上设有辅助机构和除泡机构;

[0030] 所述辅助机构包括转动管3、第一轴承4、动力组件和密封组件,所述第一轴承4的内圈安装在出料管2上,所述转动管3与出料管2同轴设置,所述出料管2的底端插入转动管3内,所述转动管3与出料管2滑动且密封连接,所述转动管3与第一轴承4的外圈固定连接,所述动力组件设置在控制箱1上且与第一轴承4的外圈传动连接,所述密封组件设置在转动管3内且位于出料管2的远离控制箱1的一侧;

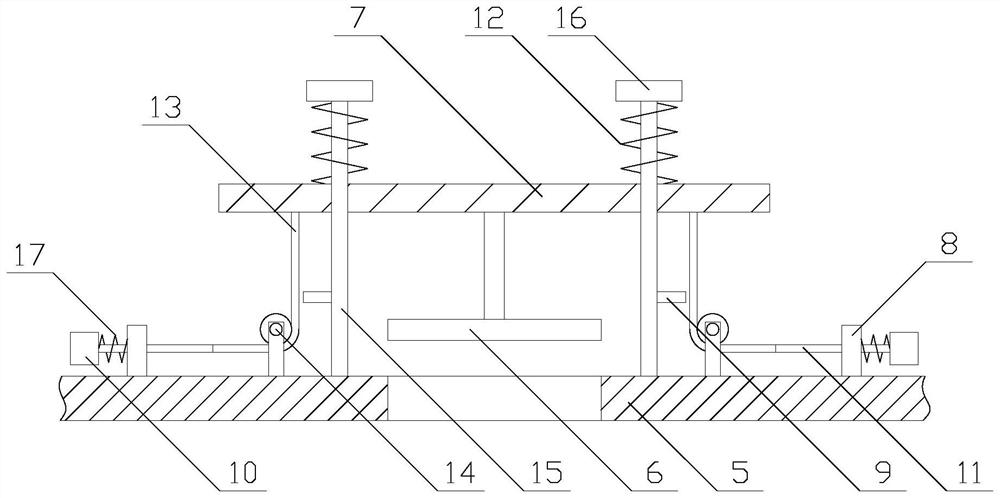

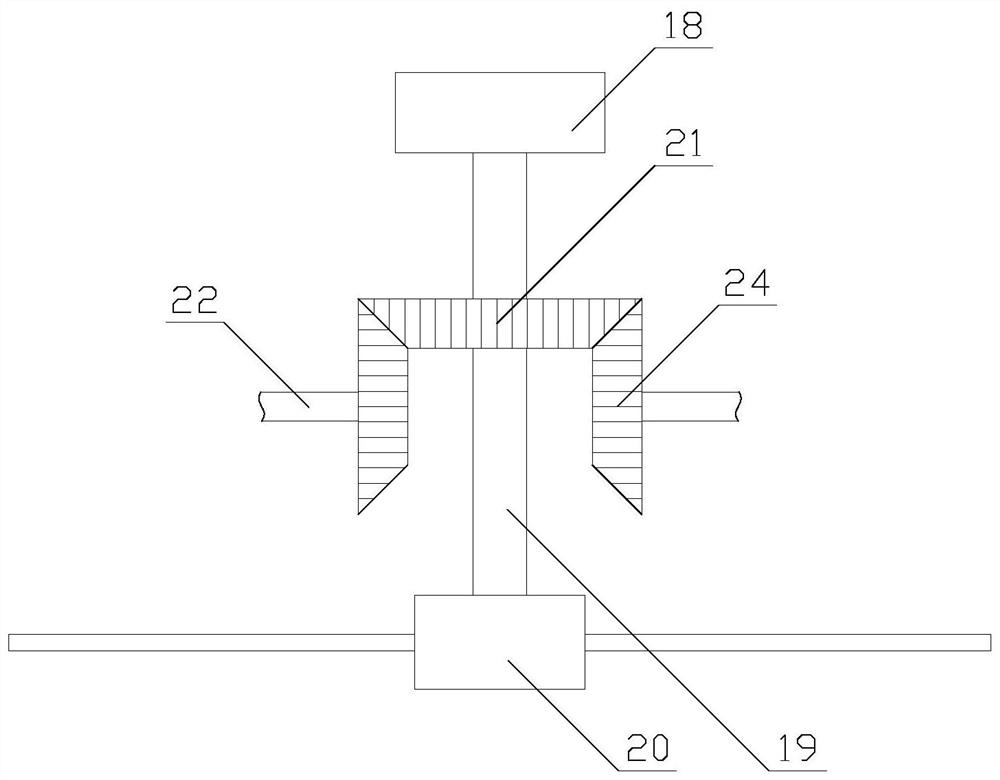

[0031] 所述密封组件包括密封环5、密封塞6、移动杆7和两个移动单元,所述密封环5与转动管3同轴设置,所述密封环5与转动管3的内壁密封且固定连接,所述密封塞6位于出料管2和密封环5之间且与密封环5匹配,所述密封塞6与密封环5之间设有间隙,所述移动杆7的轴线与转动管3的轴线垂直且橡胶,所述移动杆7位于密封塞6和出料管2之间,所述移动杆7的中端与密封塞6固定连接,所述移动单元以转动管3的轴线为中心周向均匀分布在密封环5的靠近出料管2的一侧;

[0032]The moving unit includes a support block 8, a limit block 9, a connecting block 10, a connecting rod 11, a first spring 12, a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com