A kind of pipeline quick connection flange and pipeline quick connection method

A quick connection and flange technology, applied in the direction of pipe/pipe joint/pipe fitting, flange connection, reduction of greenhouse gases, etc., can solve the problems of production and environmental loss, long construction period, large investment, etc., and achieve easy operation, convenience and speed. The effect of simple structure and connection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

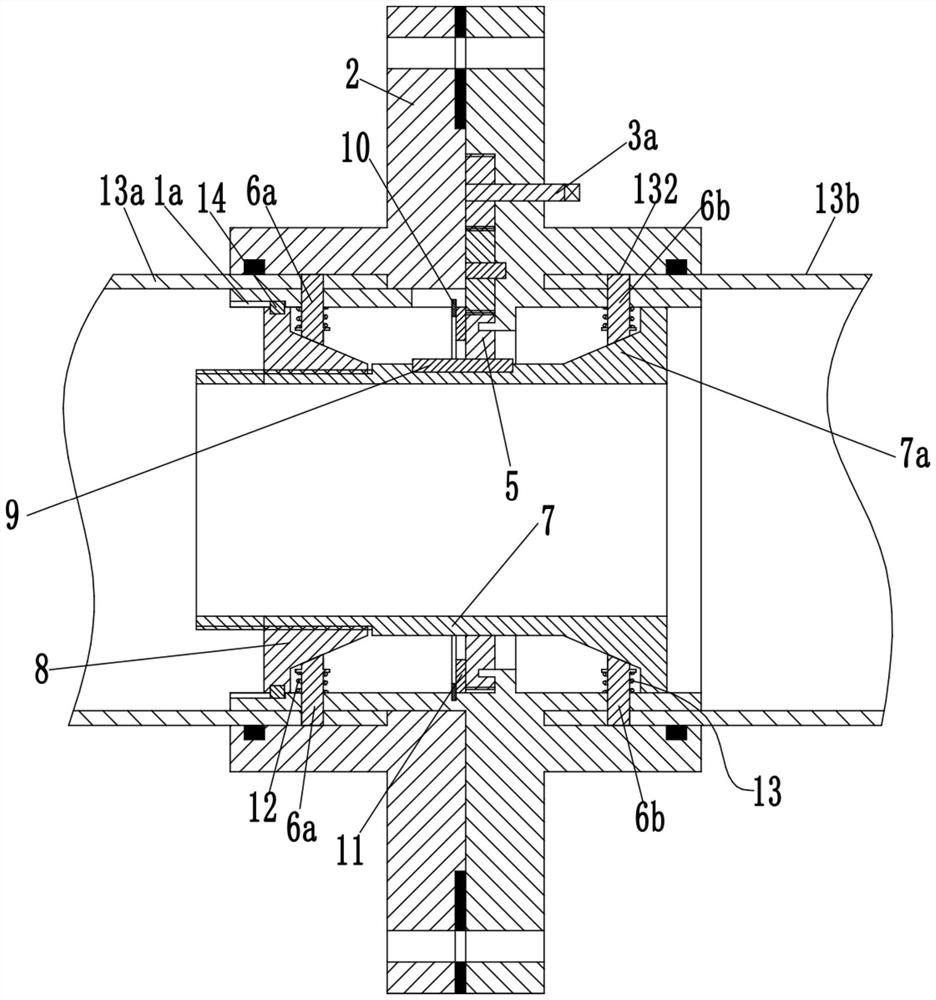

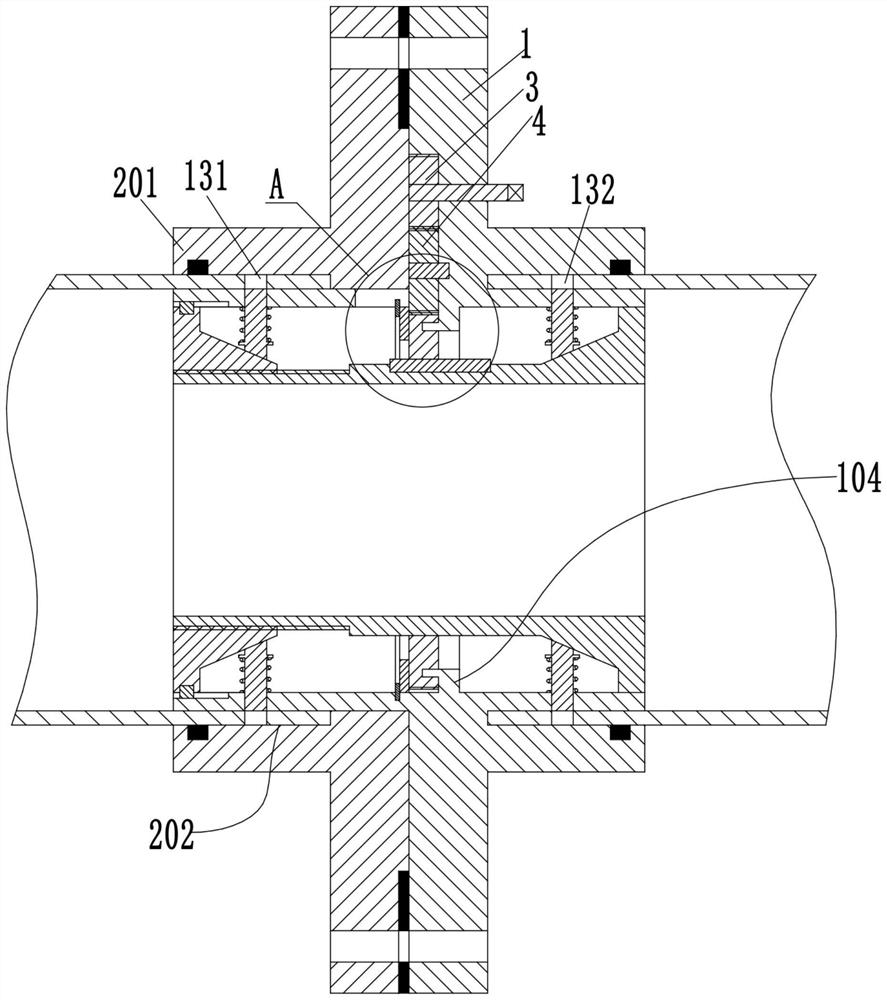

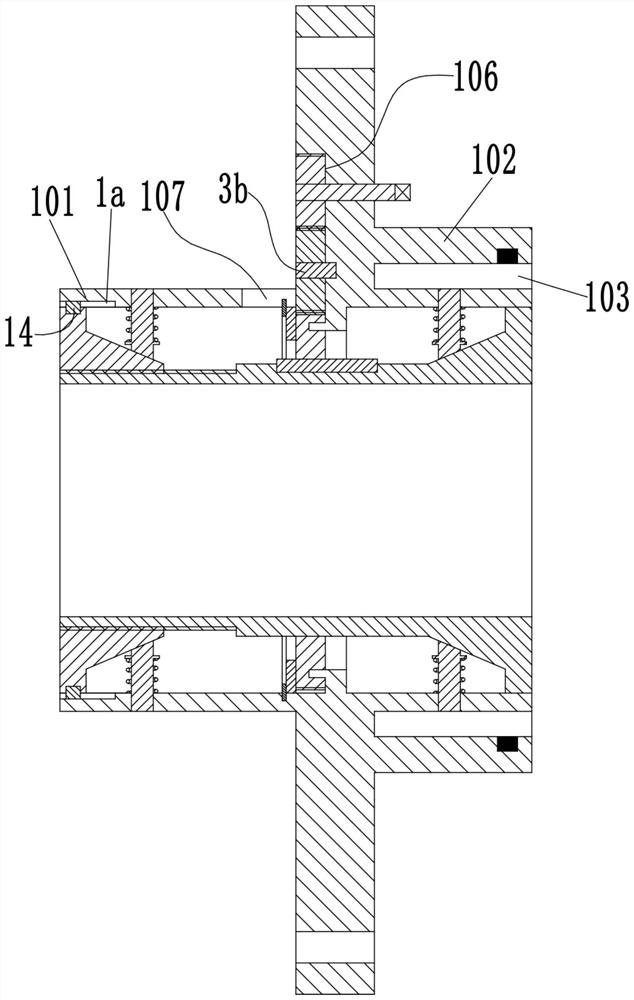

[0025] see Figure 1-5 As shown, a pipeline quick connection flange includes a first flange 2 and a second flange 1, the first flange 2 is detachably fixed on the second flange 1 through bolts; the second flange The left end of the flange 1 is extended to the left with a left cylinder 101, and the right end is extended to the right with a right cylinder 102; the left end of the first flange 2 is extended to the left and is sleeved on the outside of the left cylinder 101 The left second cylinder body 201, the left insertion slot 202 is formed between the left first cylinder body 101 and the left second cylinder body 201, and the right cylinder body 102 is provided with a right insertion slot 103 with an open right end; The inner hole side wall of the second flange 1 is provided with a convex edge 104 extending inwardly, and the left side of the convex edge 104 is rotatably connected with a gear ring 5 , and a transmission cylinder 7 is arranged in the gear ring 5 . The side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com