Drawer type switch cabinet

A switch cabinet and drawer type technology, applied in the field of electrical cabinets, can solve the problem that the drawer cannot be matched with the rear bottom plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

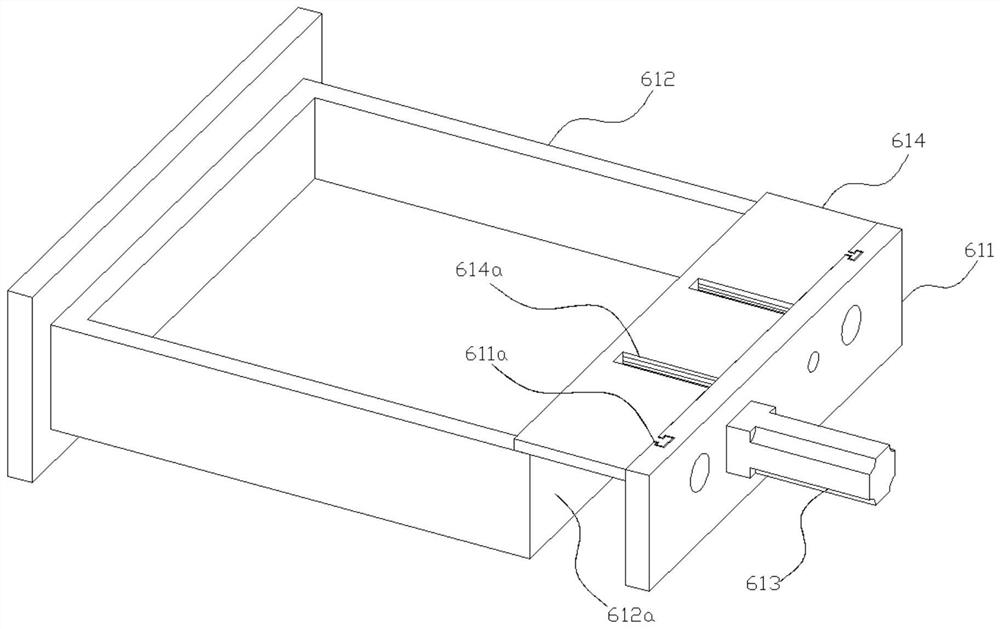

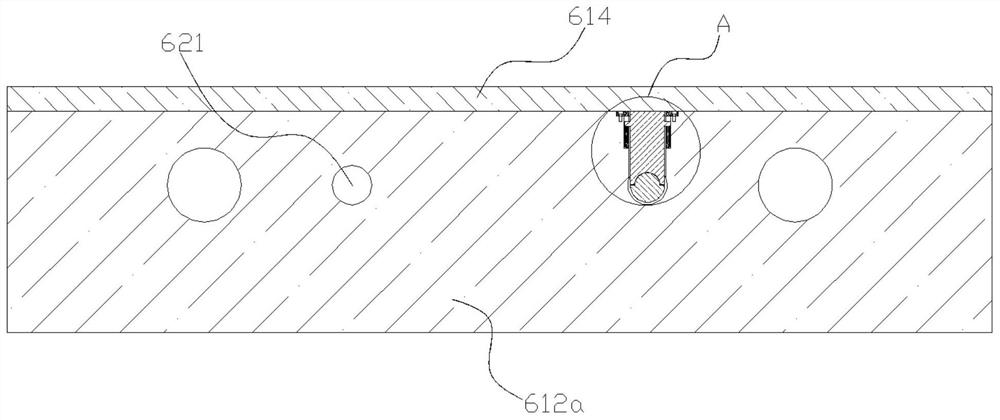

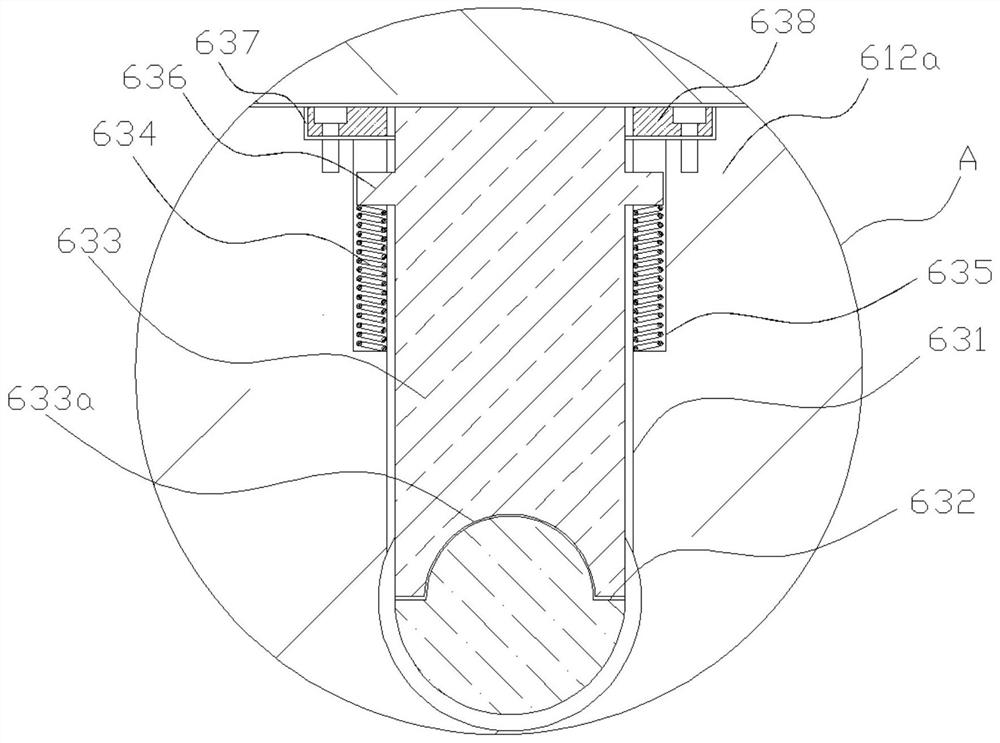

[0046] Such as Figure 1-9 As shown, the present embodiment provides a drawer-type switch cabinet, including a cabinet body, a rear bottom plate 611 fixedly connected with the cabinet body is provided in the cabinet body, and a drawer 612 located in the cabinet body is provided on one side of the rear bottom plate 611; 611 is provided with an electric push rod 613 on the end face away from the drawer 612, and the piston rod of the electric push rod 613 passes through the rear bottom plate 611 and can move toward the drawer end; the drawer 612 includes a rear side plate 612a close to the rear bottom plate 611, and There is a rear side plate through hole 621 that fits in clearance with the end of the piston rod of the electric push rod 613, and the rear side plate 612a is provided with a first elastic member that is located above the rear side plate through hole 621 and communicates with the rear side plate through hole 621 Mounting cavity 631, the end of the piston rod of the e...

Embodiment 2

[0065] Such as Figure 10-20 As shown, this embodiment provides a guide rail device, which includes a guide rail body 510, the longitudinal section of which is an "L" shape; The upper end of the 511 is provided with a mounting portion 512 perpendicular to the connecting portion 511. The mounting portion 512 is provided with a chute 512a. Block 512b; one end of the connecting portion 511 is provided with a first gear mounting cavity 521, and the first gear mounting cavity 521 is provided with a first gear 522 that can rotate along the sliding direction of the chute 512a; the bottom surface of the mounting portion 512 is installed with the first gear The cavities 521 communicate with each other, and the bottom end of the second slider 512b is provided with a second rack 531 matched with the first gear 522 .

[0066] Through the setting of the guide rail body 510, the first gear 522 and the second rack 531 in this embodiment, the connecting part 511 can be installed on the side ...

Embodiment 3

[0086] Such as Figure 1-20 As shown, this embodiment provides a switch cabinet, the cabinet body includes the guide rail drawer structure and the guide rail device described in Embodiment 1 and Embodiment 2, using the above structure, the cabinet body in this embodiment can be It is more stable and has better security when used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com