Discharging lifting cylinder lower limit detection device for lifting loading

A detection device, lifting drum technology, applied in the direction of measuring device, loading/unloading, utilization of re-radiation, etc., can solve the problem of placing it on the lower cargo box or cargo, the steel rope is detached from the reel, the lifting drum is stuck and is pulled by the car, etc. problem, to achieve the effect of preventing the copper rope from falling out of the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

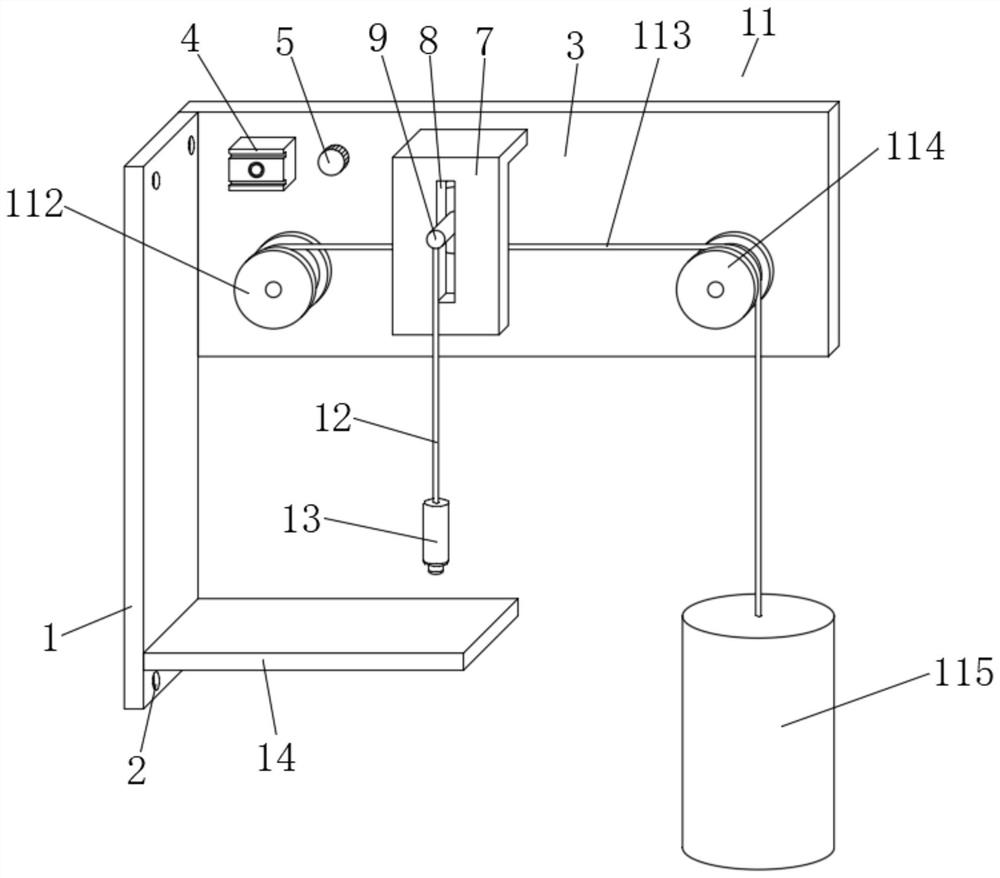

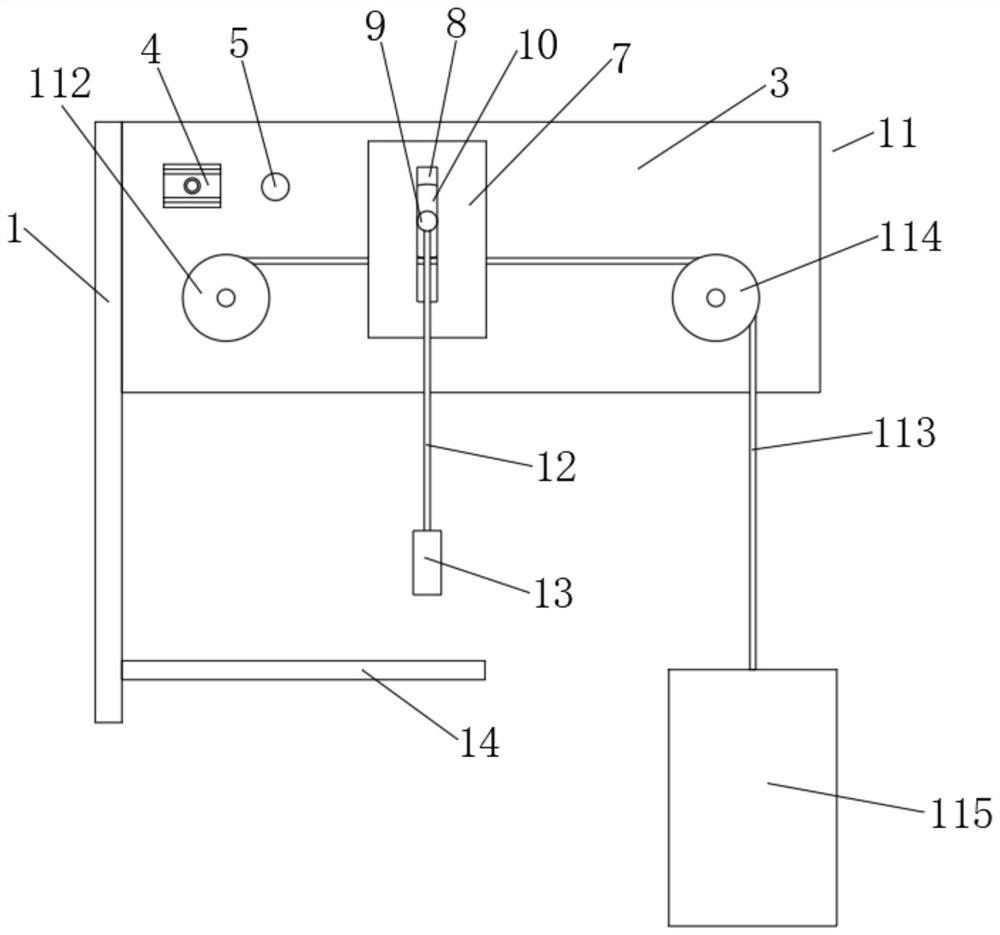

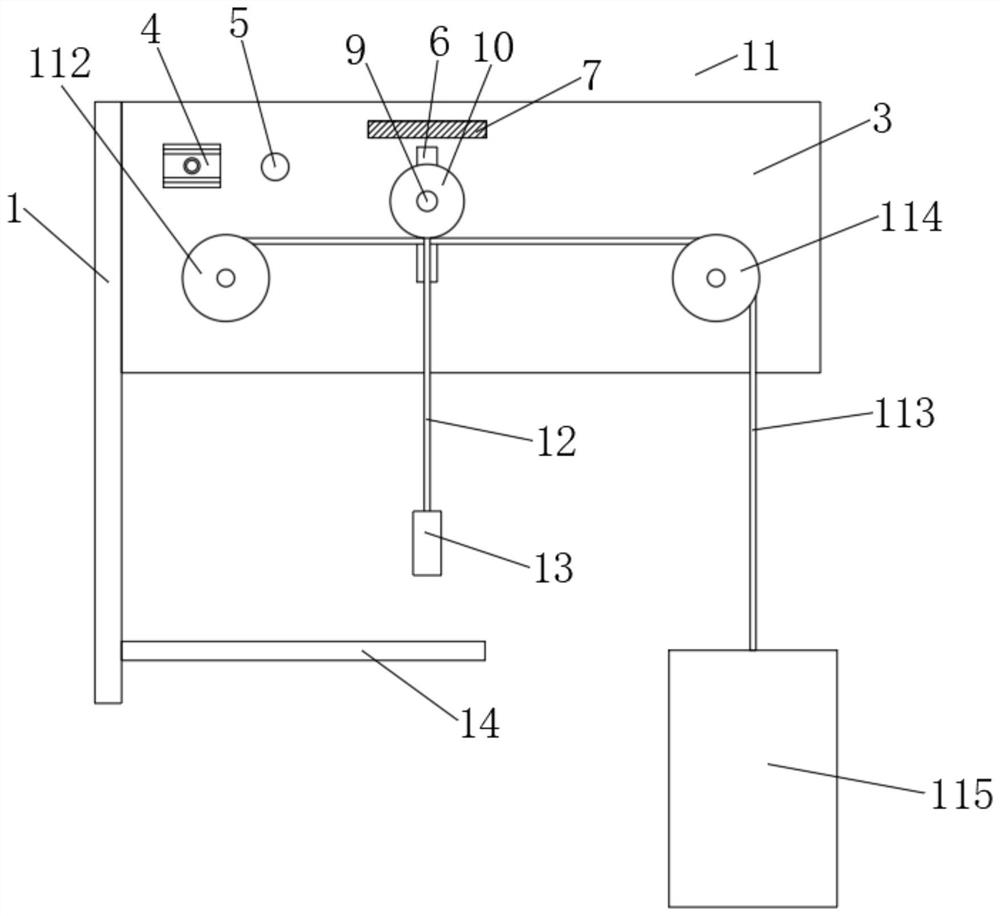

[0023] A device for detecting the lower limit of the blanking and lifting cylinder for lifting and loading vehicles, comprising a mounting plate 1, one side of the top of the mounting plate 1 is fixedly connected with a fixing plate 3, and the outer side of the fixing plate 3 is fixed and installed close to one end of the mounting plate 1 There is a processor 4, the middle part of the fixed plate 3 is provided with a first chute 6, and the outside of the fixed plate 3 is fixedly connected with a connecting plate 7 with an L-shaped structure above the first chute 6. A side of the plate 7 far away from the fixed plate 3 is provided with a second chute 8, and a slide bar 9 is slidably connected between the first chute 6 and the second chute 8, and the outside of the slide bar 9 is located on the fixed side. A detection pulley 10 is fixedly connected between the plate 3 and the connection plate 7, and a lifting mechanism 11 is arranged on the outside of the fixed plate 3 and below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com