An industrial ball valve

A ball valve and industrial technology, applied in the field of industrial ball valves, can solve problems affecting the use of ball valves, and achieve the effect of reducing the unusable valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

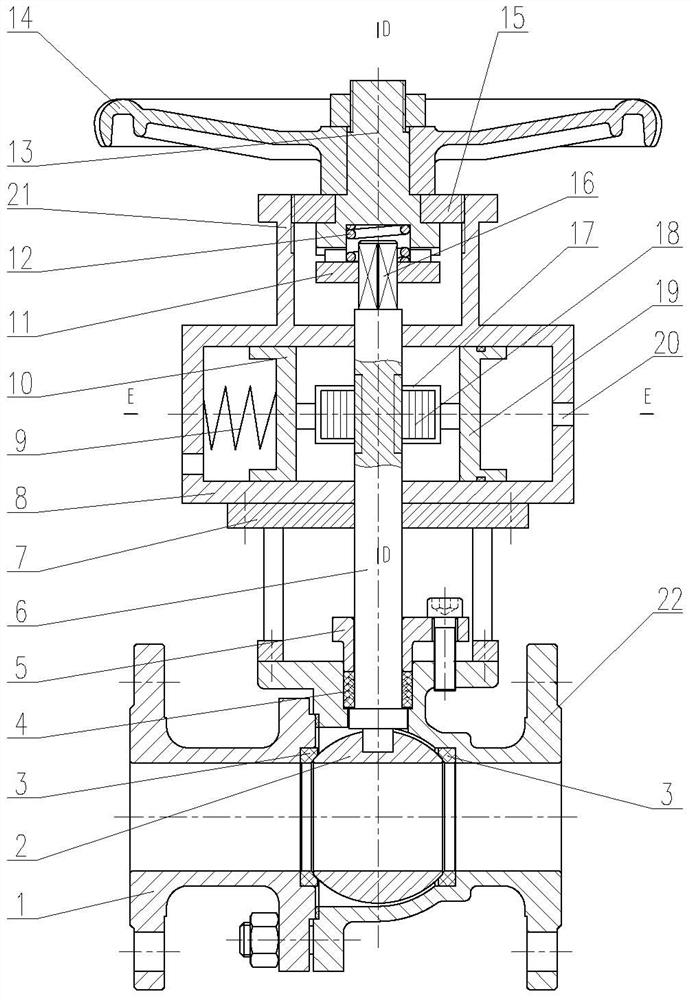

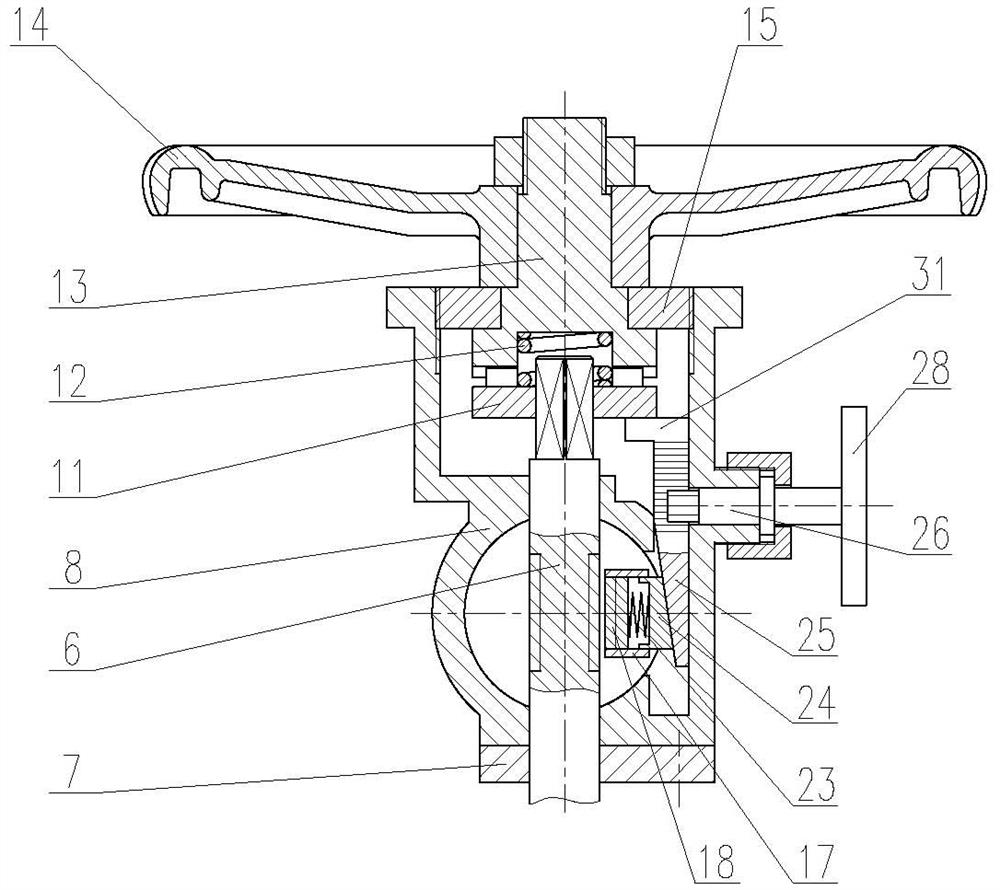

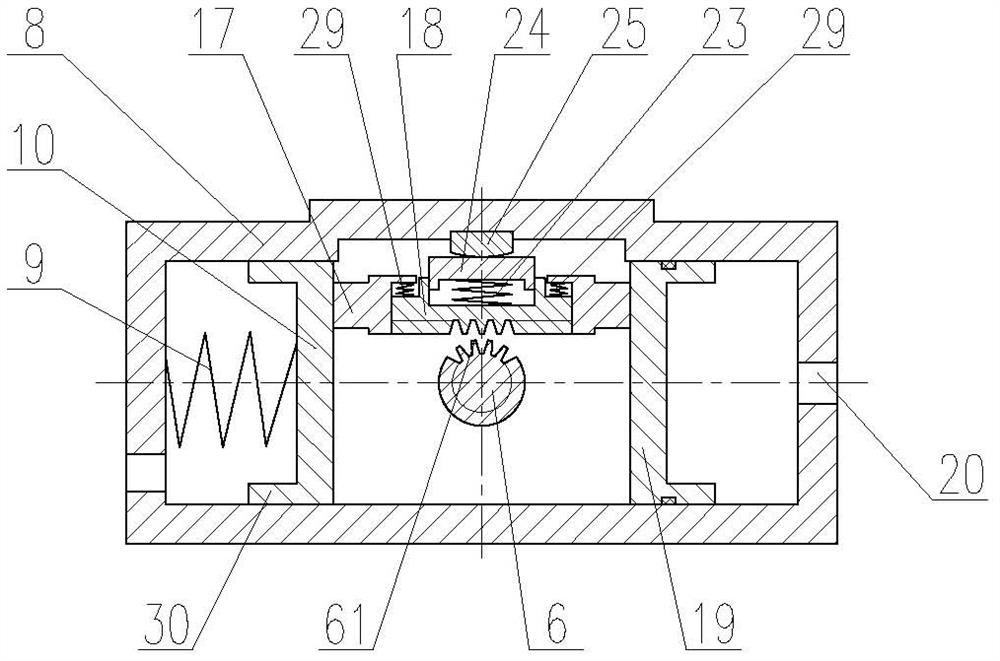

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The directional terms mentioned in the present invention, such as: up, down, left, right, inside, outside and other directional terms, are only for reference figure 1 direction. Accordingly, the directional terms used are for illustration only and not for limitation of the present invention.

[0038] Such as Figure 1-5 As shown, the present invention discloses an industrial ball valve, which includes a valve body, a ball 2 and a valve stem 6; The valve body includes a first valve body 1 and a second valve body 22 , and a valve seat 3 is provided between the first valve body 1 , the second valve body 22 and the ball 2 . The upper part of the second valve body 22 close to the side of the first valve body 1 is provided with a valve stem opening matching with the valve stem 6 , and the lower end of the valve stem 6 is connected to the ball 2 thro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap