Zigzag sewing machine

A sewing machine, a zigzag technology, applied in the direction of sewing machine components, sewing machine needle holder, sewing machine ring mechanism, etc., can solve the problems such as inability to sew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

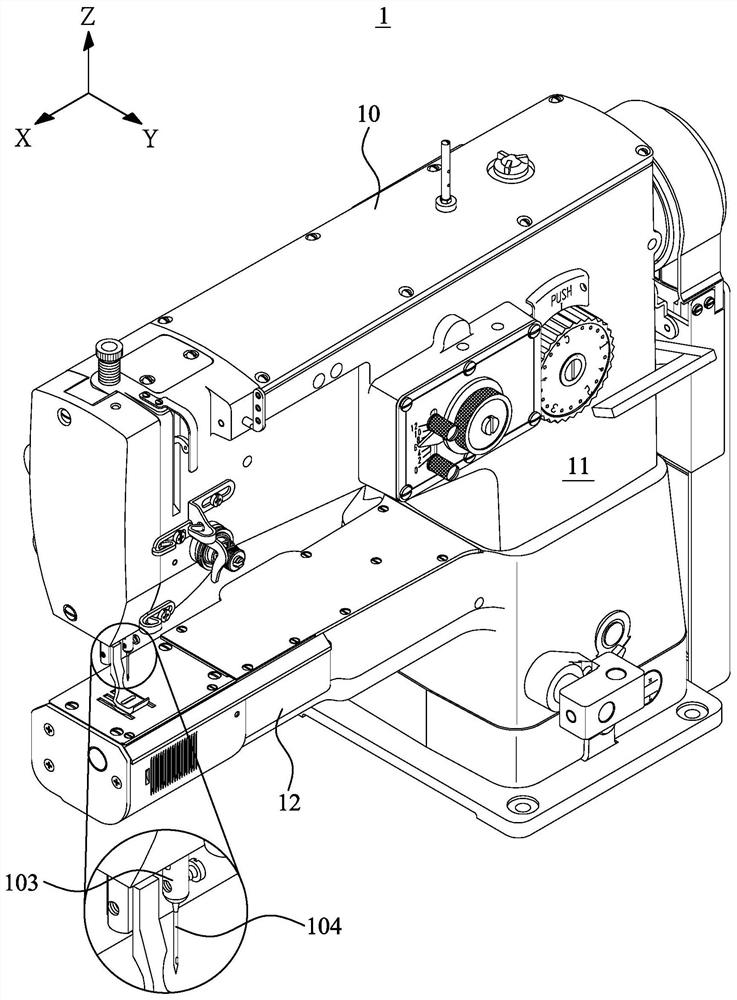

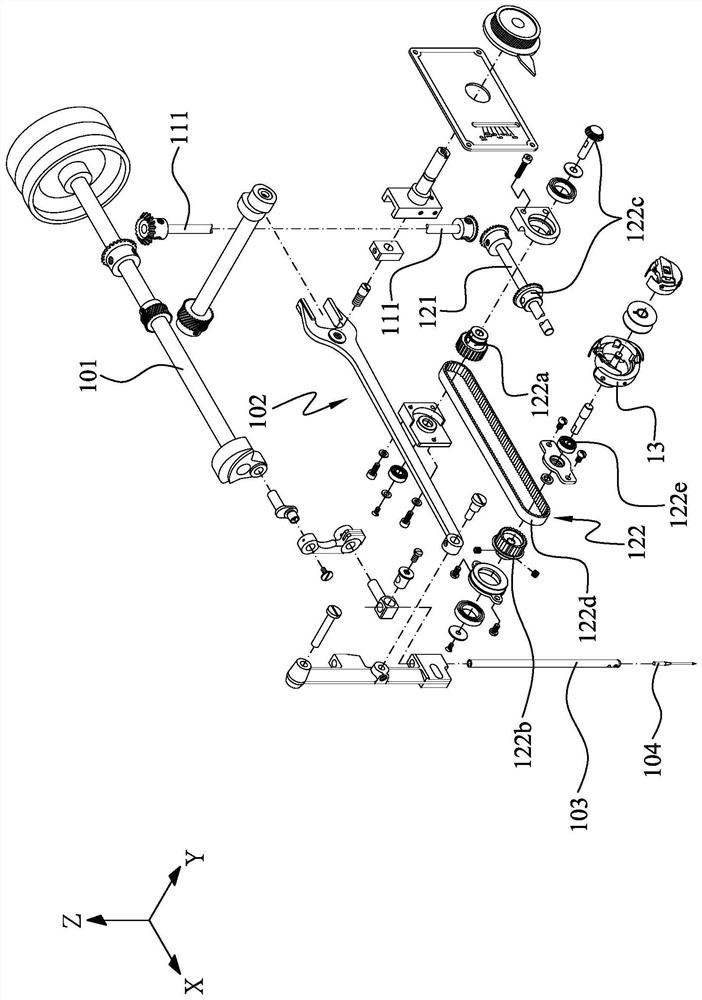

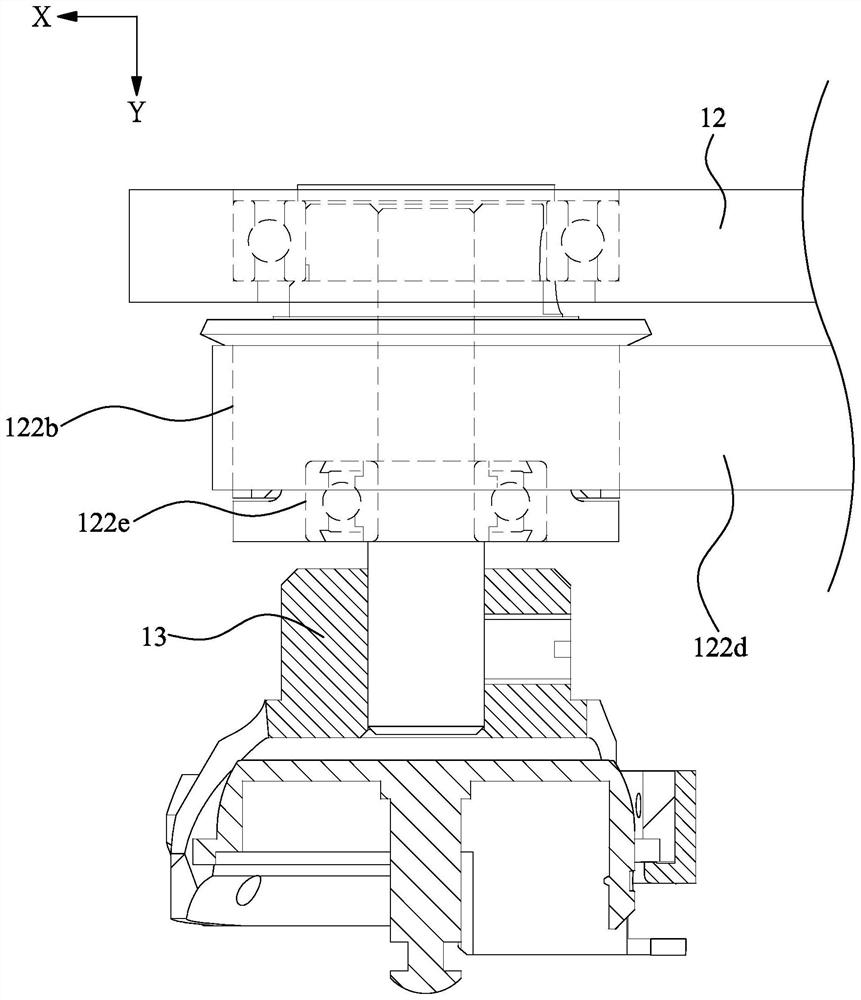

[0029] see Figure 4 and Figure 5 As shown, the zigzag sewing machine 2 of the present invention has a body 20, the body 20 has a head 21 and a pillar 22, the inside of the head 21 has an upper shaft 23 parallel to the X axis, and the upper shaft 23 is connected to a needle bar 24, when the upper shaft 23 rotates around the X-axis direction, the upper shaft 23 can drive the needle bar 24 to move up and down along the Z-axis direction, so that a machine needle 25 connected to the needle bar 24 is synchronously moved along the Move back and forth along the Z-axis direction, as shown in the figure, the needle bar 24 is equipped with a swing mechanism 26 located inside the headstock 21, the swing mechanism 26 is connected to the upper shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com