Microwave oven

A technology for a microwave oven and a bottom plate is applied in the field of microwave ovens, and can solve the problems of reduced performance of microwave ovens and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Various embodiments of the heat dissipation structure of the microwave oven according to the present invention will be specifically described below with reference to FIGS. 6 to 12 .

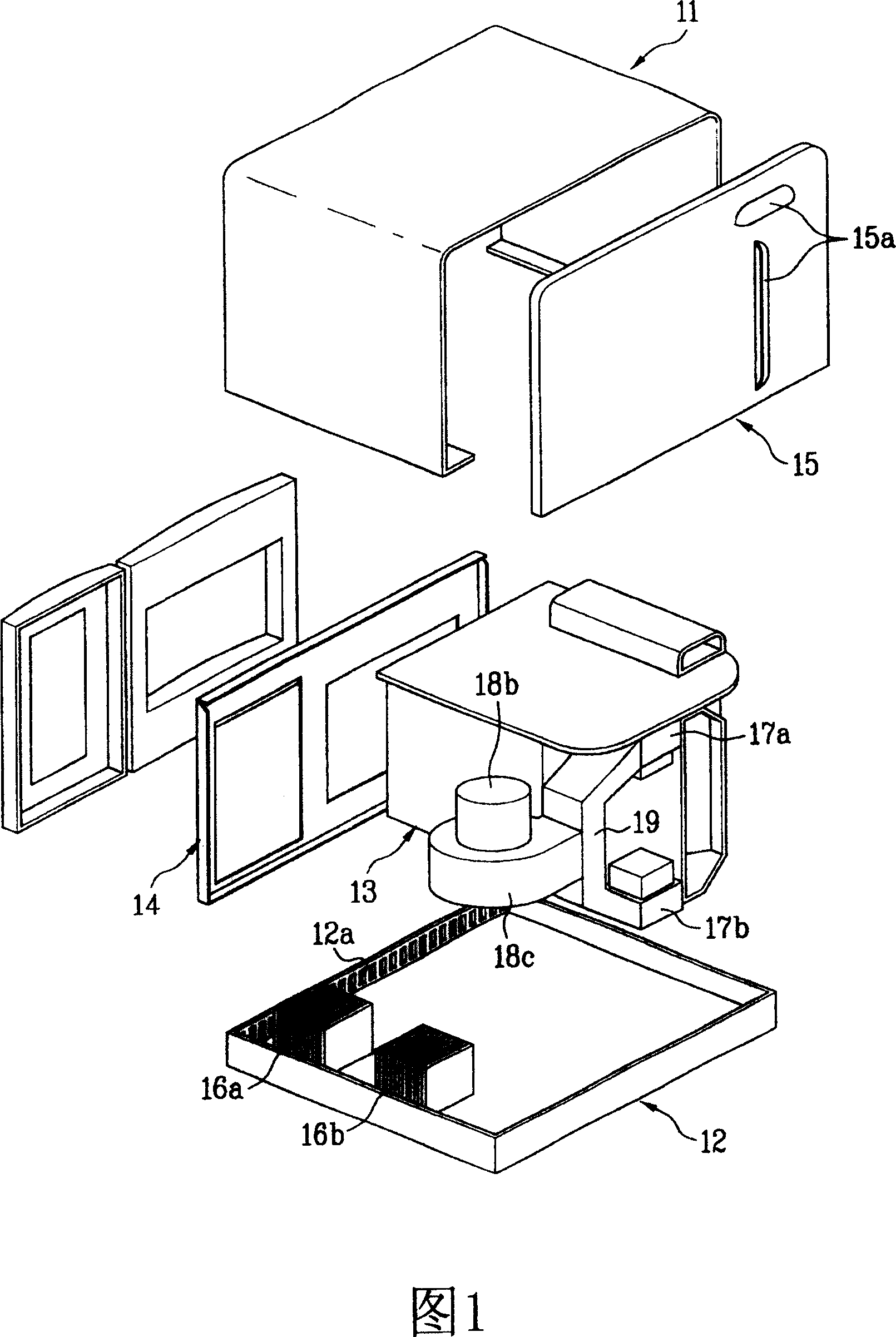

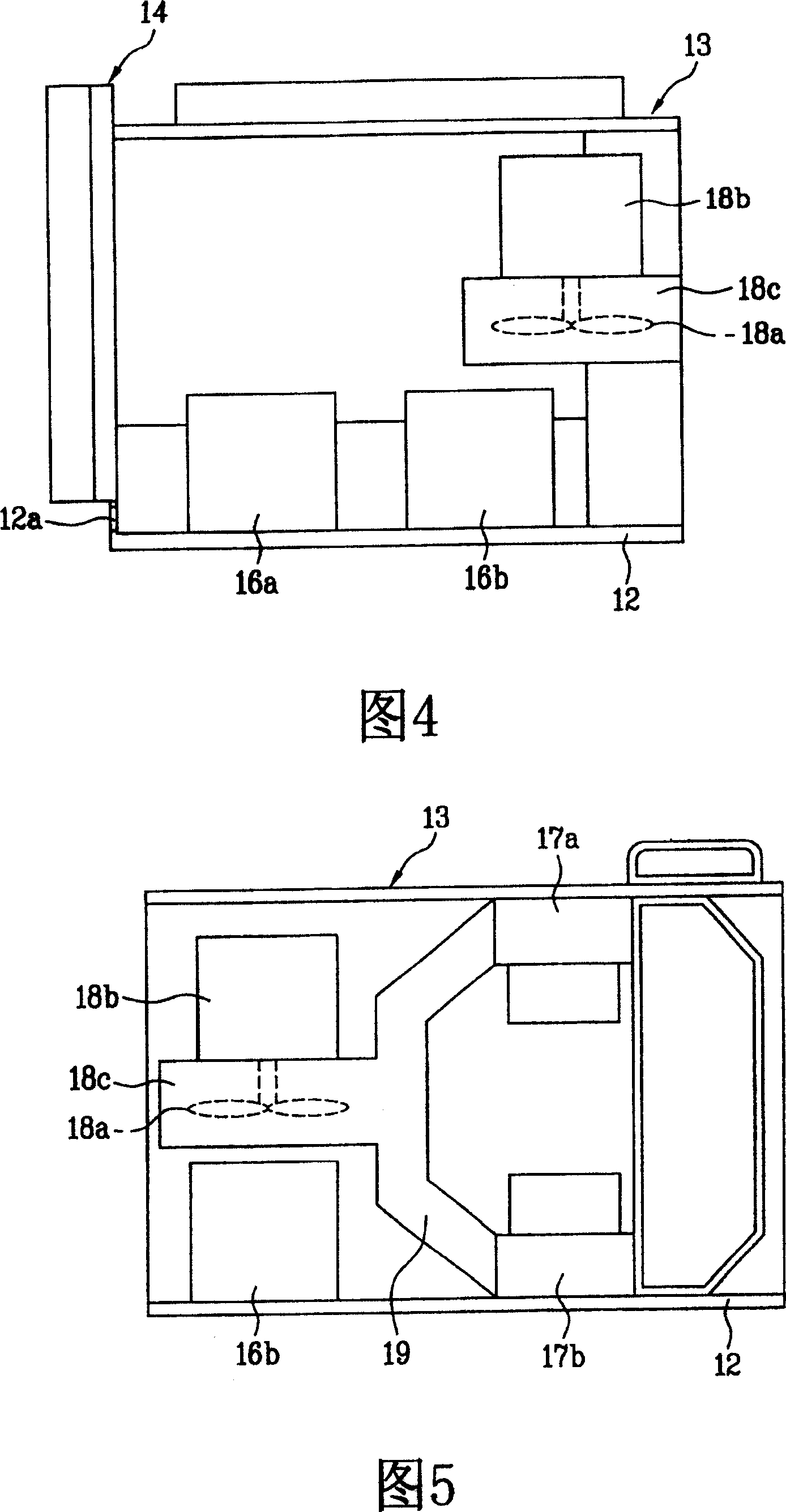

[0060] At first, adopt the first embodiment of the microwave oven of the present invention as shown in Figure 6, generally comprise the following parts, namely: shell 110, bottom plate 120, cavity 130, front panel 140, rear panel 150, a pair of transformers 161,162, A pair of magnetrons 171 , 172 , a blower fan 181 , a fan motor 182 , a fan cover 183 and an air duct 190 .

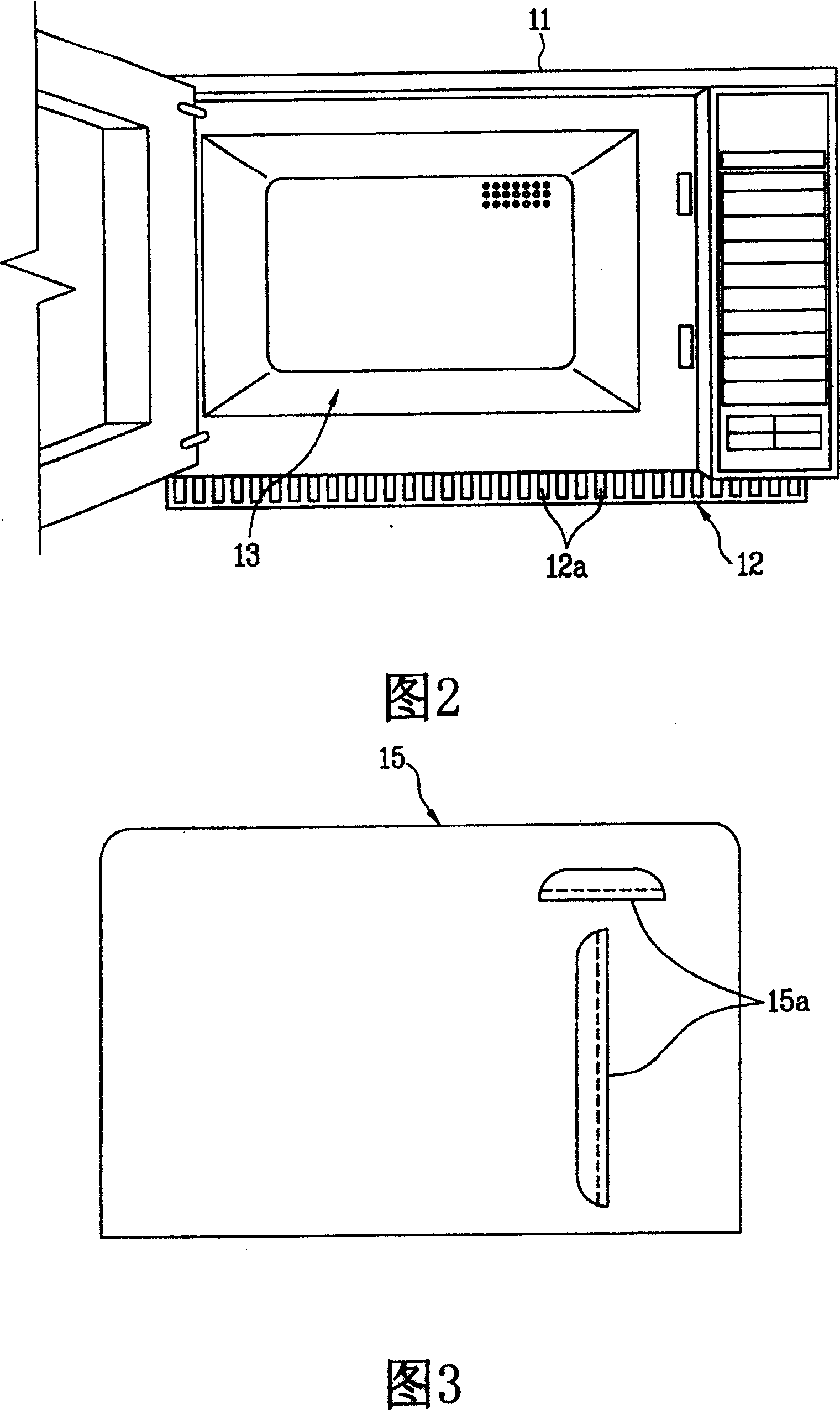

[0061] The shell 110 forms the two sides and the top of the microwave oven, and the bottom plate 120 , the front panel 140 and the rear panel 150 are respectively connected to the top of the shell 110 .

[0062] In addition, the bottom plate 120 forms the bottom surface of the microwave oven, on which a cavity 130 is disposed, and an electric control room is formed on one side of the cavity 130 .

[0063] Here, various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com