A kind of plate shape control method of titanium plate

A technology of plate shape control and titanium plate, applied in the field of metallurgy, which can solve the problems of waste products, many waste products, buckle heads and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment rolls titanium plate Ti3111, and the coil number is 99A109001.

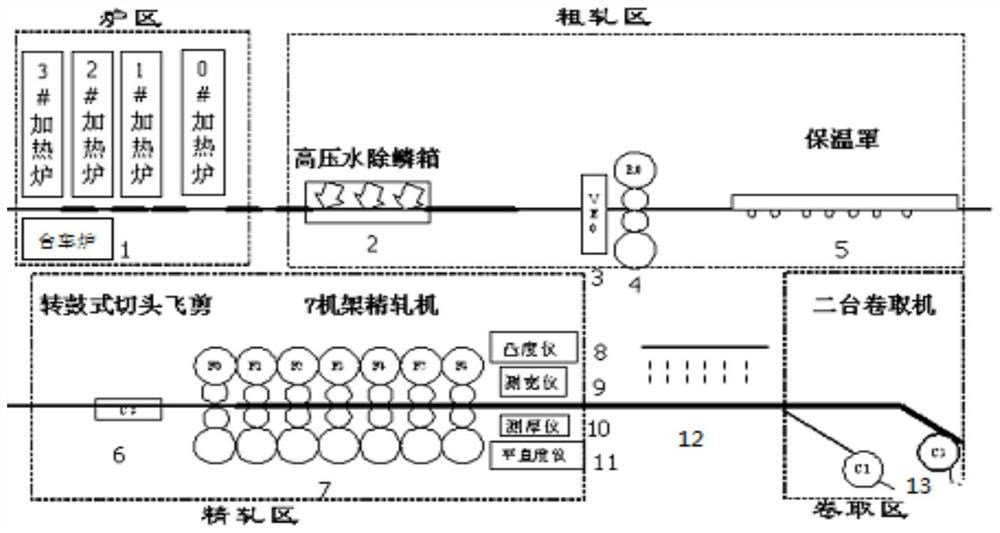

[0063] The specifications of the billet are: thickness 172mm, width 1078mm, length 8040mm; the thickness of the rough rolling exit is 35mm, and the specifications of the finished product are: thickness 5.2mm, width 1084mm, and the target temperature is 690°C.

[0064] The titanium plate billet is heated in a trolley furnace, and the target temperature for exiting the furnace is 880°C. After exiting the furnace, the rough rolling adopts seven-pass rolling, and the exit thickness is 35mm.

[0065] 1) Calculation of rough rolling parameters:

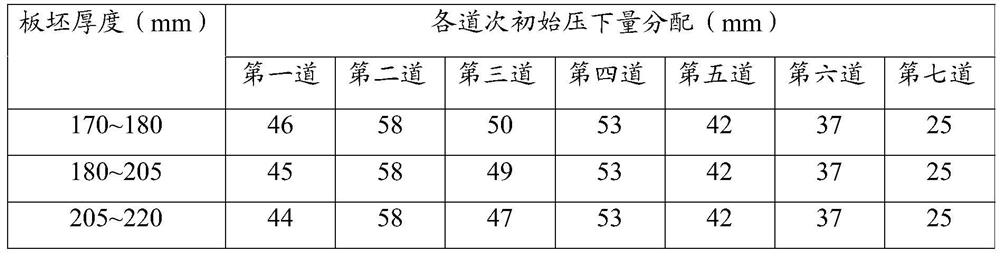

[0066] The thickness of the blank is 172mm. According to Table 1, the initial reductions (mm) of the seven passes are determined to be 46, 58, 50, 53, 42, 37, and 25, respectively. The total lateral pressure is -6mm. According to Table 2, determine the maximum lateral pressure (mm) of the 1st, 3rd, 5th, and 7th passes as: 5, 10, 10, and 10, respectively...

Embodiment 2

[0077] In this embodiment, the rolled titanium plate TA3 has a coil number of 99A139502.

[0078] The specifications of the billet are: thickness 201mm, width 1138mm, length 7110mm; rough rolling exit thickness 35mm, finished product specification: thickness 7.0mm, width 1132mm, target temperature 690°C.

[0079] The titanium plate billet is heated in a trolley furnace, and the target temperature for exiting the furnace is 880°C. After exiting the furnace, the rough rolling adopts seven-pass rolling, and the exit thickness is 35mm.

[0080] 1) Calculation of rough rolling parameters:

[0081] The thickness of the billet is 201 mm. According to Table 1, the initial reductions (mm) of the seven passes are determined to be 45, 58, 49, 53, 42, 37, and 25, respectively. The total lateral pressure is 6mm. According to Table 2, the maximum lateral pressure (mm) of the 1st, 3rd, 5th, and 7th passes is determined to be 20, 20, 20, and 15, respectively. The rolling parameters of rough...

Embodiment 3

[0092] In this embodiment, the rolled titanium plate TA1 has a coil number of 99B100101.

[0093] The specifications of the billet are: thickness 209mm, width 1235mm, length 8001mm; rough rolling exit thickness 35mm, finished product specification: thickness 8.1mm, width 1220mm, target temperature 690°C.

[0094] The titanium plate billet is heated in a trolley furnace, and the target temperature for exiting the furnace is 880°C. After exiting the furnace, the rough rolling adopts seven-pass rolling, and the exit thickness is 35mm.

[0095] 1) Calculation of rough rolling parameters:

[0096] The thickness of the blank is 209mm. According to Table 1, the initial reductions (mm) of the seven passes are determined to be 44, 58, 47, 53, 42, 37, and 25, respectively. The total lateral pressure is 15mm. According to Table 2, the maximum lateral pressure (mm) of the 1st, 3rd, 5th, and 7th passes is determined to be 25, 30, 20, and 20, respectively. The rolling parameters of rough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com